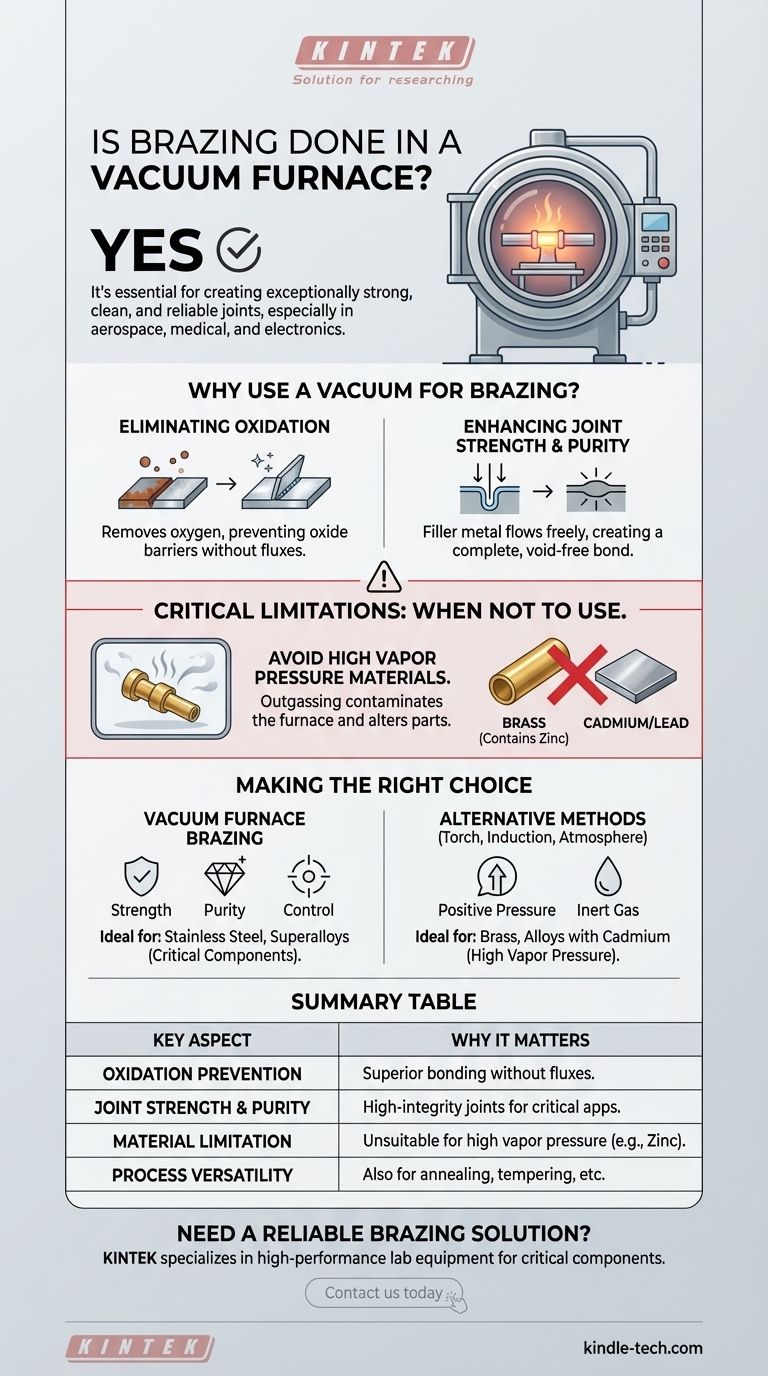

Yes, brazing is frequently performed in a vacuum furnace. This method is essential for creating exceptionally strong, clean, and reliable joints. Industries such as aerospace, medical, and electronics rely on vacuum furnace brazing for critical components where joint integrity and purity are non-negotiable.

The core purpose of using a vacuum furnace for brazing is not just to heat the parts, but to create a highly controlled, active environment. By removing oxygen and other reactive gases, the vacuum prevents oxidation, enabling the brazing alloy to form a superior metallurgical bond without the need for chemical fluxes.

Why Use a Vacuum for Brazing?

The decision to braze in a vacuum furnace is driven by the need for ultimate control over the joining process. The vacuum itself is a critical tool that fundamentally changes how the metals interact at high temperatures.

Eliminating Oxidation and Contamination

At brazing temperatures, most metals react instantly with oxygen in the air, forming oxides on the surface. These oxide layers act as a barrier, preventing the brazing filler metal from properly wetting and bonding with the parent materials.

A vacuum furnace removes virtually all the air, eliminating the risk of oxidation. This results in bright, clean parts straight from the furnace, with no discoloration or scaling.

Enhancing Joint Strength and Purity

Because the metal surfaces remain perfectly clean, the filler metal can flow freely into the joint through capillary action. This creates a complete, void-free metallurgical bond, maximizing the strength and reliability of the final assembly.

Furthermore, the process is inherently clean because it doesn't require the use of chemical fluxes, which can leave behind corrosive residues and become points of failure.

Enabling Other Thermal Processes

Vacuum furnaces are versatile. The same equipment can be used for other critical thermal processes like annealing, tempering, and stress-relieving. This allows for multi-step manufacturing sequences to be performed with exceptional control in a single environment.

Critical Limitations: When Not to Use a Vacuum Furnace

While powerful, vacuum furnace brazing is not a universal solution. The physics of operating in a vacuum introduces specific limitations that make it unsuitable for certain materials.

The Problem with High Vapor Pressure

A vacuum dramatically lowers the boiling point of elements. Materials that contain elements with a high vapor pressure will "boil off" or outgas at brazing temperatures when under a vacuum.

This outgassing contaminates the inside of the furnace and, more importantly, can alter the chemical composition and structural integrity of the parts being brazed.

Why Brass and Similar Alloys are Unsuitable

This is precisely why brass should never be brazed in a vacuum furnace. Brass is an alloy of copper and zinc, and zinc has a very high vapor pressure.

When heated in a vacuum, the zinc will vaporize out of the brass alloy. This damages the workpiece and coats the furnace interior with zinc deposits, which can ruin subsequent jobs. The same rule applies to materials containing cadmium or lead.

Making the Right Choice for Your Goal

Selecting the correct brazing method depends entirely on your materials and the performance requirements of the final joint.

- If your primary focus is maximum joint purity and strength for critical components (like stainless steel or superalloys): Vacuum furnace brazing is the ideal choice for its clean, fluxless, and highly controlled environment.

- If your primary focus is joining materials containing high vapor pressure elements (like brasses or alloys with cadmium): You must use an alternative method like torch, induction, or furnace brazing with a positive pressure of an inert gas atmosphere.

Ultimately, understanding the interaction between your materials and the brazing environment is the key to producing a successful joint.

Summary Table:

| Key Aspect | Why It Matters for Brazing |

|---|---|

| Oxidation Prevention | Eliminates surface oxides, enabling superior metallurgical bonding without fluxes. |

| Joint Strength & Purity | Creates clean, void-free, high-integrity joints for critical applications. |

| Material Limitation | Unsuitable for materials with high vapor pressure elements (e.g., zinc in brass). |

| Process Versatility | The same furnace can be used for annealing, tempering, and stress-relieving. |

Need a reliable brazing solution for your critical components? KINTEK specializes in high-performance lab equipment, including vacuum furnaces ideal for brazing stainless steel, superalloys, and other demanding materials. Our experts can help you select the right equipment to achieve maximum joint strength, purity, and process control. Contact us today to discuss your specific application and ensure flawless results.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What metals can be joined by brazing? Discover the Versatility of Modern Brazing Techniques

- What are vacuum furnaces used for? Unlock Ultimate Material Purity and Performance

- What is the major advantage that brazing has over welding? Joining Dissimilar Metals with Ease

- What is the difference between welding and vacuum brazing? Choose the Right Joining Method for Your Project

- What is the process of a vacuum furnace? Achieve Purity and Precision in High-Temp Processing