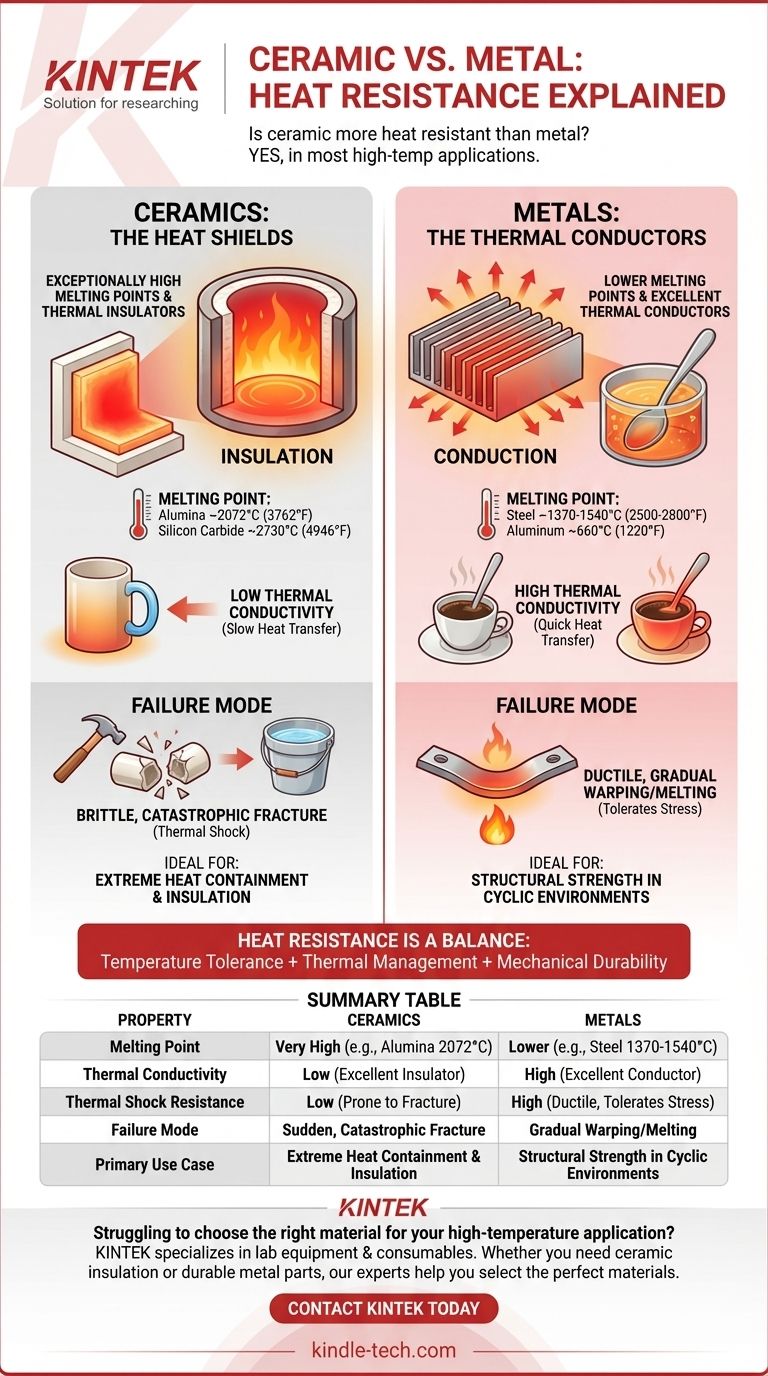

In almost all high-temperature applications, yes, ceramics are significantly more heat resistant than metals. This is because engineering ceramics possess exceptionally high melting points and act as thermal insulators, meaning they transfer heat very slowly. In contrast, most metals have lower melting points and are excellent thermal conductors, readily absorbing and distributing heat throughout their structure.

True heat resistance is more than just a high melting point. It's a complex interplay between a material's ability to withstand temperature, its reaction to sudden temperature changes (thermal shock), and its capacity to transfer heat.

What "Heat Resistance" Really Means

The term "heat resistance" is not a single property but a combination of several distinct material characteristics. Understanding these is key to selecting the right material for a high-temperature environment.

Melting Point: The Absolute Limit

The most direct measure of heat resistance is the temperature at which a material transitions from a solid to a liquid. Here, ceramics have a clear advantage.

Most common structural metals, like steel, melt around 1370-1540°C (2500-2800°F). Aluminum melts at a much lower 660°C (1220°F).

In contrast, technical ceramics can withstand far higher temperatures. Alumina oxide melts at 2072°C (3762°F), and silicon carbide doesn't even melt at atmospheric pressure—it decomposes at 2730°C (4946°F).

Thermal Conductivity: The Speed of Heat Transfer

Thermal conductivity measures how quickly heat passes through a material. This is where the functional difference between metals and ceramics becomes most apparent.

Metals are thermal conductors. They have high thermal conductivity, which is why a metal spoon in hot coffee quickly becomes hot to the touch. This property is useful for heat sinks, where the goal is to draw heat away from a component.

Ceramics are thermal insulators. They have very low thermal conductivity, which is why a ceramic coffee mug keeps your drink hot while the handle stays cool. This makes them ideal for applications like furnace linings or heat shields, where the goal is to contain heat and prevent it from transferring.

Thermal Expansion and Thermal Shock

All materials expand when heated and contract when cooled. How a material manages this movement is critical.

Metals generally have a higher coefficient of thermal expansion but are also ductile. This means they can bend and deform without breaking, allowing them to tolerate the internal stresses caused by temperature changes.

Ceramics typically have lower thermal expansion but are extremely brittle. If heated or cooled too quickly, different parts of the material expand or contract at different rates, creating immense internal stress that can cause it to crack or shatter. This phenomenon is known as thermal shock.

Understanding the Trade-offs: Brittleness vs. Ductility

The choice between ceramic and metal is rarely about a single property. It is almost always a trade-off between the ceramic's temperature tolerance and the metal's durability.

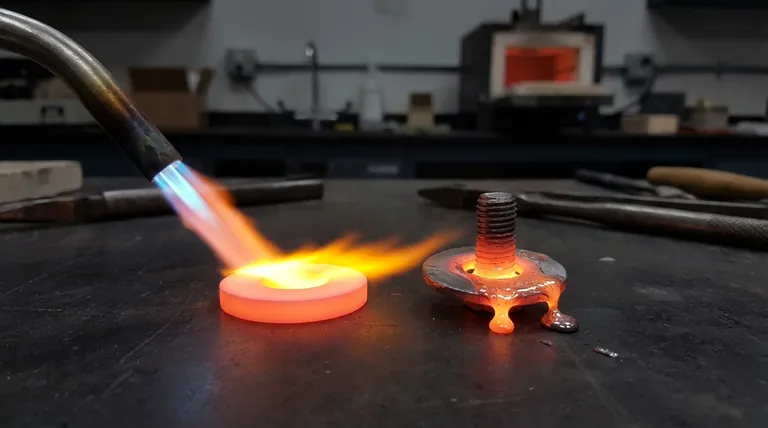

The Failure Mode of Metals: Bending and Melting

When a metal part is pushed beyond its temperature limit, it typically fails in a predictable way. It will first lose its strength (a process called creep), then begin to warp, bend, and eventually melt. This failure is often gradual, providing warning signs.

The Failure Mode of Ceramics: Catastrophic Fracture

When a ceramic fails due to thermal stress, the failure is sudden, complete, and catastrophic. Think of a hot glass dish shattering when cold water is poured into it. There is no bending or warning—just a fracture. This makes ceramics unsuitable for applications involving rapid temperature cycles or high mechanical impact.

Machinability and Cost

Metals are relatively easy to machine, form, weld, and repair. This makes manufacturing complex metal components cost-effective.

Ceramics are extremely hard and brittle, making them very difficult and expensive to shape. They are typically formed into a near-final shape and then fired (sintered), with any final shaping requiring difficult and costly diamond grinding.

Making the Right Choice for Your Application

Selecting the right material requires you to define your primary goal. Is it pure temperature survival, or is it mechanical reliability under thermal stress?

- If your primary focus is containing extreme heat and providing insulation: Technical ceramics are the superior choice due to their exceptionally high melting points and low thermal conductivity.

- If your primary focus is structural strength in a high-heat, high-vibration, or cycling environment: A specialized metal superalloy (like Inconel) is often better, as its ductility prevents catastrophic failure from thermal shock and mechanical stress.

- If your primary focus is cost-effectiveness for a moderate-heat application: Standard metals like steel or aluminum are almost always the most practical and economical solution.

Ultimately, selecting the right material depends on understanding that heat resistance is a balance between temperature tolerance, thermal management, and mechanical durability.

Summary Table:

| Property | Ceramics | Metals |

|---|---|---|

| Melting Point | Very High (e.g., Alumina: 2072°C) | Lower (e.g., Steel: 1370-1540°C) |

| Thermal Conductivity | Low (Excellent Insulator) | High (Excellent Conductor) |

| Thermal Shock Resistance | Low (Prone to Fracture) | High (Ductile, Tolerates Stress) |

| Failure Mode | Sudden, Catastrophic Fracture | Gradual Warping/Melting |

| Primary Use Case | Extreme Heat Containment & Insulation | Structural Strength in Cyclic Environments |

Struggling to choose the right material for your high-temperature application? KINTEK specializes in lab equipment and consumables, providing expert solutions for your laboratory needs. Whether you require ceramic components for superior heat insulation or durable metal parts for mechanical reliability, our team can help you select the perfect materials to enhance your lab's efficiency and safety. Contact us today to discuss your specific requirements and discover how KINTEK can support your high-temperature challenges!

Visual Guide

Related Products

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Hexagonal Boron Nitride HBN Ceramic Ring

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is the role of zirconia fiber felt in Si2N2O synthesis? Ensuring Thermal Efficiency and Electrical Safety

- What is ceramic insulation used for? Master High-Temperature Solutions for Industrial Efficiency

- Can ceramic withstand high temperatures? Discover the Superior Materials for Extreme Heat

- What are the disadvantages of ceramic fiber? Key Handling & Durability Risks Explained

- What insulating materials can tolerate maximum temperature? Select the Right High-Temp Insulator for Your Application