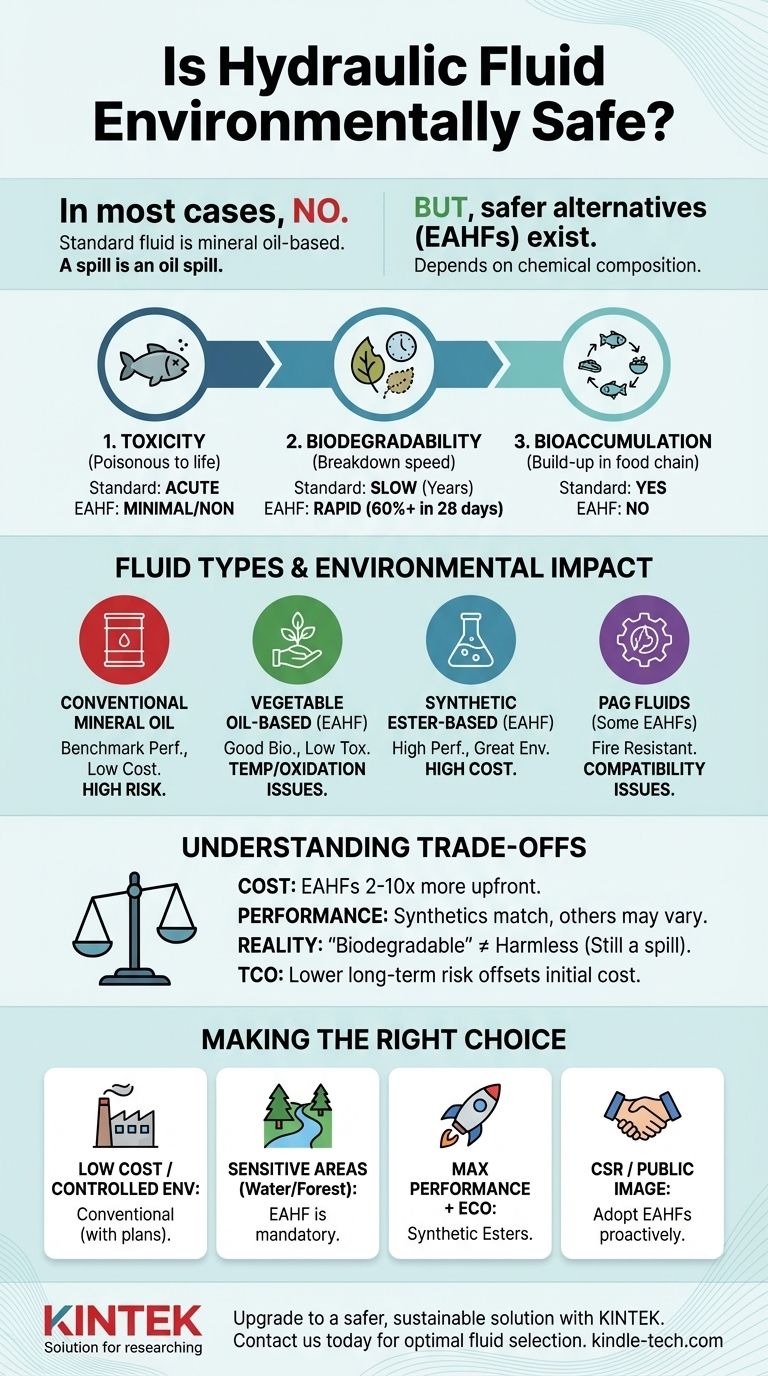

In most cases, no. Standard hydraulic fluid is mineral oil-based, derived from petroleum. A spill of this conventional fluid is effectively an oil spill, posing a significant threat to soil, groundwater, and aquatic life due to its toxicity and persistence in the environment. However, a class of "environmentally acceptable" fluids now offers a much safer alternative.

The environmental safety of a hydraulic fluid is not a simple yes or no question; it depends entirely on its chemical composition. While conventional fluids are hazardous pollutants, Environmentally Acceptable Hydraulic Fluids (EAHFs) are specifically designed to be less toxic and readily biodegradable, though they come with distinct performance and cost considerations.

What Determines a Fluid's Environmental Impact?

To understand the risks, we must look at the three primary metrics used to evaluate a fluid's impact on the environment following a leak or spill. These factors are determined by the fluid's base oil.

The Role of the Base Oil

The foundation of any hydraulic fluid is its base oil. Conventional fluids use mineral oil (petroleum), while environmentally acceptable fluids use base oils like vegetable oils (canola, sunflower) or engineered synthetic esters. This fundamental difference is the primary driver of its environmental profile.

Key Environmental Metric: Toxicity

Toxicity measures how poisonous the substance is to life, particularly aquatic organisms like fish and invertebrates. Conventional mineral oils are acutely toxic, meaning exposure can cause immediate harm or death. EAHFs are formulated to be minimally toxic or non-toxic.

Key Environmental Metric: Biodegradability

Biodegradability is the speed at which microorganisms can break the fluid down into harmless substances like carbon dioxide and water. Mineral oils are not readily biodegradable and can persist in the environment for years. EAHFs, by contrast, must be readily biodegradable, typically breaking down by over 60% within 28 days.

Key Environmental Metric: Bioaccumulation

Bioaccumulation is the tendency for a substance to build up in an organism's tissues over time, concentrating as it moves up the food chain. The persistent chemicals in mineral oil can bioaccumulate, posing a long-term threat. EAHFs are designed to be non-bioaccumulative.

A Breakdown of Hydraulic Fluid Types

Understanding the main categories is crucial for making an informed choice. Each has a different profile balancing performance, cost, and environmental impact.

Conventional Mineral Oil-Based Fluids

This is the default and most common type of hydraulic fluid. It is highly effective, well-understood, and the least expensive option. Its performance is the benchmark against which all others are measured, but its environmental record is poor. Think of it as the gasoline of the hydraulics world: powerful and cheap, but hazardous if spilled.

Vegetable Oil-Based Fluids

Often derived from canola (rapeseed) or sunflower oils, these fluids are a common type of EAHF. They offer excellent biodegradability and low toxicity. However, their primary weakness can be poor performance at temperature extremes and a tendency to oxidize (break down) faster than other types.

Synthetic Ester-Based Fluids

These are high-performance EAHFs engineered in a lab for both durability and environmental safety. They offer the best of both worlds: excellent performance across a wide temperature range, long service life, and the required low toxicity and high biodegradability. They are, however, the most expensive option.

Polyalkylene Glycol (PAG) Fluids

PAGs are another category of synthetics known for excellent lubricity and fire resistance. Certain water-soluble PAGs are also readily biodegradable and have low toxicity, making them an EAHF option for specific applications. However, they are often incompatible with standard seals and paints, requiring careful system consideration.

Understanding the Trade-offs: EAHFs vs. Conventional Fluids

Choosing an environmentally acceptable fluid is not a simple swap. You must weigh the benefits against clear operational trade-offs.

The Cost Factor

There is no avoiding it: EAHFs are more expensive upfront. Vegetable-oil-based fluids can be 2-3 times the cost of mineral oil, while high-performance synthetic esters can be 5-10 times more expensive.

Performance and Compatibility

While synthetic EAHFs can match or exceed the performance of mineral oils, some vegetable-based fluids may not offer the same service life or protection in high-pressure, high-temperature systems. Furthermore, switching fluid types may require flushing the system and checking for compatibility with seals and hoses to prevent leaks.

The Reality of "Biodegradable"

"Biodegradable" does not mean "harmless." A spill of EAHF is still a spill. It must be reported and cleaned up according to regulations. The key benefit is that any unrecovered fluid will break down much faster and cause significantly less long-term ecological damage than a mineral oil spill.

Total Cost of Ownership

The higher initial price of an EAHF can be offset by a lower total cost of ownership. In the event of a spill, cleanup costs, regulatory fines, and reputational damage can be dramatically lower. For some organizations, this risk mitigation is worth the premium price.

Making the Right Choice for Your Operation

The decision to use an EAHF should be based on a clear-eyed assessment of your operational risk, budget, and environmental goals.

- If your primary focus is minimizing upfront cost and equipment operates in a controlled environment with low spill risk: Conventional mineral oil is a viable choice, provided you have stringent spill-control plans in place.

- If your equipment operates near waterways, in forestry, or on other sensitive land: An Environmentally Acceptable Hydraulic Fluid (EAHF) is often mandatory and the only responsible option.

- If your primary focus is maximizing performance while also meeting environmental goals: High-performance synthetic esters offer the best balance of durability and biodegradability, justifying their premium cost in critical applications.

- If your corporate social responsibility (CSR) and public image are key drivers: Adopting EAHFs across your fleet demonstrates a proactive commitment to environmental stewardship that goes beyond simple compliance.

Ultimately, choosing the right hydraulic fluid is a strategic decision that balances operational needs with environmental responsibility.

Summary Table:

| Fluid Type | Base Oil | Biodegradability | Toxicity | Best Use Case |

|---|---|---|---|---|

| Conventional Mineral Oil | Petroleum | Not Readily Biodegradable | High (Acutely Toxic) | Low-risk, cost-sensitive operations |

| Vegetable Oil-Based (EAHF) | Canola, Sunflower | Readily Biodegradable | Low/Non-Toxic | Sensitive environments, moderate performance needs |

| Synthetic Ester-Based (EAHF) | Engineered Esters | Readily Biodegradable | Low/Non-Toxic | High-performance, extreme temperatures |

| PAG Fluids (Some EAHFs) | Synthetic Glycols | Readily Biodegradable (Water-Soluble) | Low/Non-Toxic | Specific applications requiring fire resistance |

Upgrade to a safer, more sustainable hydraulic solution with KINTEK.

Choosing the right hydraulic fluid is critical for both your equipment's performance and your environmental responsibilities. At KINTEK, we specialize in providing high-quality laboratory equipment and consumables, including environmentally acceptable hydraulic fluids (EAHFs) tailored to your specific operational needs. Whether you're working in sensitive ecosystems or aiming to enhance your corporate sustainability profile, our experts can help you select the optimal fluid to minimize environmental risk while maximizing efficiency.

Let KINTEK support your commitment to a greener future—contact us today for a personalized consultation!

Visual Guide

Related Products

- Hexagonal Boron Nitride HBN Ceramic Ring

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

- E Beam Crucibles Electron Gun Beam Crucible for Evaporation

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

People Also Ask

- What is the purpose of boron nitride spray on graphite foil in titanium hot pressing? Enhance Purity and Release

- What role does a Boron Nitride (BN) sleeve play in cold sintering mold assemblies? Essential Electrical Insulation

- What is the function of a BN inner liner in a graphite mold during Flash Sintering? Master Precise Current Control

- What is the purpose of applying a boron nitride (BN) coating to graphite molds? Enhance Sintering Release & Precision

- Why is Boron Nitride utilized as a coating for graphite molds? Protect Your Mo-Na Powder During Sintering