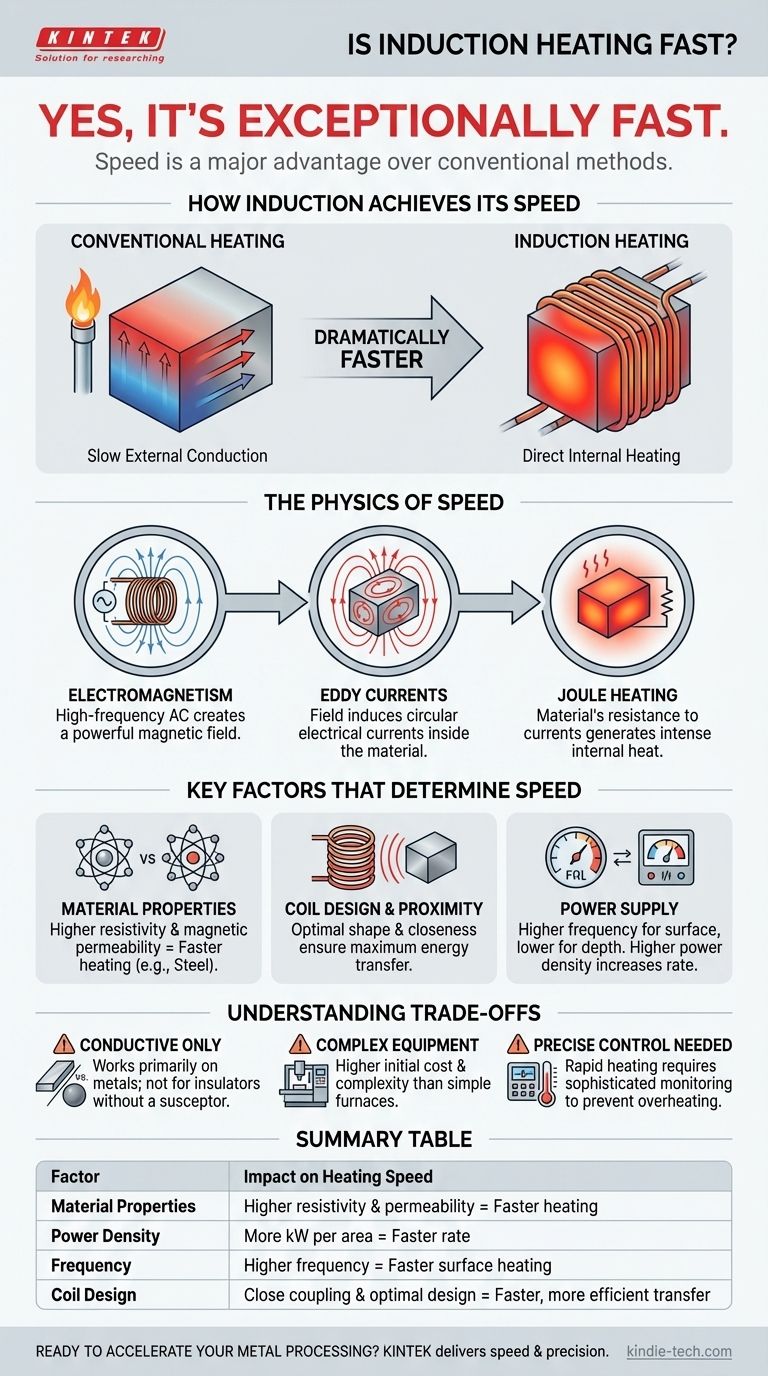

Yes, induction heating is exceptionally fast. Its speed is one of its most significant advantages over conventional heating methods. Unlike a furnace or flame that heats a material's surface and waits for that heat to conduct inward, induction generates heat directly inside the material itself, resulting in a dramatically faster and more efficient process.

The core reason for induction's speed is its unique mechanism: it uses a magnetic field to turn the workpiece into its own heat source. This bypasses the slow, inefficient process of thermal conduction from an external element, allowing for nearly instantaneous and highly localized heating.

How Induction Achieves Its Speed

To understand why induction is so rapid, we need to look at the physics that drive the process. It's a clean and direct conversion of electrical energy into heat within the target material.

The Principle of Electromagnetism

An induction heater uses a coil of conductive material (typically copper) through which a high-frequency alternating current (AC) is passed. This creates a powerful and rapidly changing magnetic field around the coil.

Generating Heat from Within (Eddy Currents)

When a conductive workpiece, like a piece of steel, is placed within this magnetic field, the field induces circular electrical currents inside the metal. These are known as eddy currents.

The Role of Electrical Resistance

The workpiece material naturally resists the flow of these eddy currents. This resistance converts the electrical energy into intense heat, a principle known as Joule heating. It's like microscopic friction, generating heat uniformly throughout the path of the currents.

Key Factors That Determine Heating Speed

While induction is inherently fast, the exact speed depends on several critical factors. Optimizing these variables is key to achieving maximum performance for a specific application.

Material Properties

The electrical resistivity and magnetic permeability of the workpiece are paramount. Materials with higher resistivity generate more heat. For ferrous metals like iron and steel, their high magnetic permeability below a certain temperature (the Curie point) greatly enhances the heating effect, making them ideal candidates for rapid induction heating.

Coil Design and Proximity

The induction coil is the component that transfers energy to the part. Its design—shape, number of turns, and proximity to the workpiece—is critical. A well-designed coil that is closely coupled to the part ensures the maximum amount of magnetic flux is intercepted, leading to more efficient and faster heating.

Power Supply Frequency and Density

The frequency of the alternating current determines the depth at which the eddy currents circulate. Higher frequencies lead to shallower heating, which is perfect for rapid surface hardening. Lower frequencies penetrate deeper for applications like through-heating or forging. Higher power density (more kilowatts applied to a smaller area) will, of course, also increase the heating rate.

Understanding the Trade-offs of Speed

The remarkable speed of induction comes with specific requirements and limitations that must be considered. It is not a universal solution for all heating tasks.

Material Limitations

The most significant constraint is that induction heating only works directly on electrically conductive materials, primarily metals. It cannot heat insulators like plastics, glass, or most ceramics unless a conductive susceptor is used to transfer heat indirectly.

Equipment Complexity and Cost

Induction systems, consisting of a power supply and a custom-designed coil, are more technologically complex and typically have a higher initial capital cost than a simple resistance furnace or gas torch.

The Need for Precise Control

Because the heating is so rapid and localized, precise control is essential to prevent overheating, warping, or melting the workpiece. This requires sophisticated power controls and often thermal monitoring systems, adding to the system's complexity.

Making the Right Choice for Your Application

Selecting the right heating method depends entirely on your specific goals for speed, precision, material, and budget.

- If your primary focus is rapid, repeatable surface hardening or brazing: Induction heating is almost certainly the superior choice due to its speed and precise control.

- If your primary focus is bulk heating large batches or non-metallic materials: A conventional convection or radiation furnace is a more practical and effective solution.

- If your primary focus is low-cost, simple heating without tight process control: A simpler method like a gas forge or resistance oven may be more economical, despite being significantly slower.

By understanding the principles behind its speed, you can leverage induction heating as a powerful tool for modern manufacturing where it delivers the most impactful results.

Summary Table:

| Factor | Impact on Heating Speed |

|---|---|

| Material Properties | Higher resistivity & permeability = Faster heating |

| Power Density | More kW per area = Faster rate |

| Frequency | Higher frequency = Faster surface heating |

| Coil Design | Close coupling & optimal design = Faster, more efficient transfer |

Ready to Accelerate Your Metal Processing?

Induction heating from KINTEK delivers the speed and precision your laboratory or production line needs. Our expertise in lab equipment and consumables ensures you get a system tailored for rapid hardening, brazing, or heating applications.

Contact us today to discuss how our induction solutions can enhance your efficiency and results.

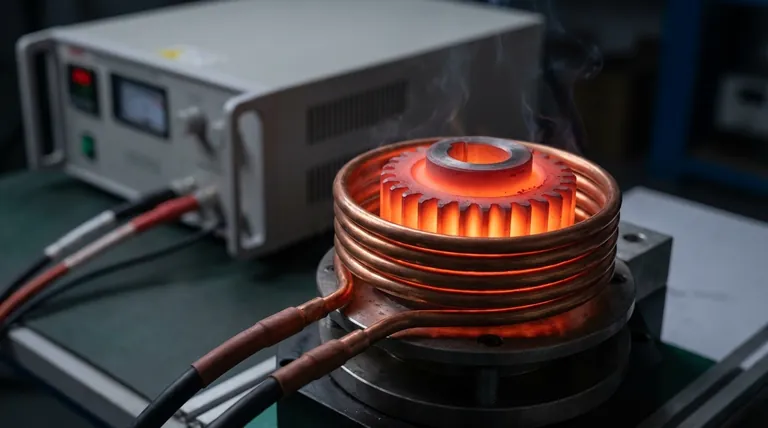

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- How does a vacuum hot press furnace improve the density of Ti2AlN ceramics? Achieve 98.5%+ Density & Superior Strength

- What role does a vacuum hot pressing sintering furnace play in the fabrication of CuCrFeMnNi alloys? Achieve High Purity

- Why is it necessary to maintain a high-vacuum environment within a vacuum hot press furnace? Optimize Cu-SiC Sintering

- What is the primary role of the Vacuum Hot Pressing Sintering Furnace? Prepare High-Purity W-Si Alloy Targets

- What role does the pressure system of a vacuum hot pressing furnace play? Optimize Ti-Al Laminated Composite Density