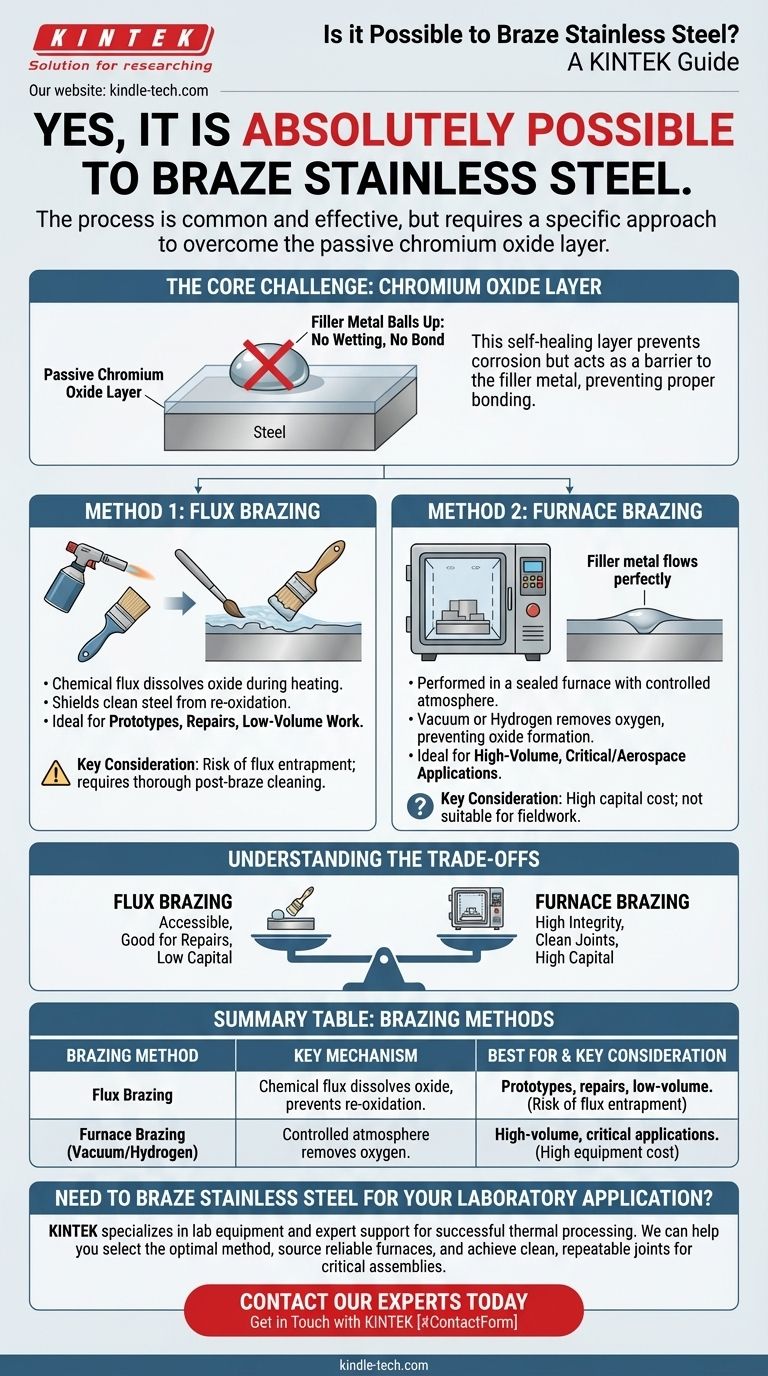

Yes, it is absolutely possible to braze stainless steel. The process is common and highly effective, but it requires a specific approach. Unlike plain carbon steel, stainless steel has a passive, self-healing layer of chromium oxide that gives it corrosion resistance, but this same layer prevents the molten braze filler metal from properly bonding to the surface.

Brazing stainless steel is a standard industrial practice, but success is entirely dependent on overcoming the tenacious chromium oxide layer on its surface. This is typically achieved using either a specialized chemical flux or a controlled atmosphere furnace.

The Core Challenge: The Chromium Oxide Layer

The key to understanding how to braze stainless steel is to first understand why it's "stainless." The solution to the brazing challenge lies in temporarily defeating this protective property.

What is This Protective Layer?

The chromium within the stainless steel alloy reacts with oxygen in the air to form a very thin, dense, and transparent layer of chromium oxide.

This passive layer is what prevents rust and corrosion. If scratched, it instantly reforms, providing continuous protection.

Why It Prevents a Good Braze Joint

Brazing works when a molten filler metal is drawn into a joint by capillary action and "wets" the surfaces of the parent metals. Wetting is the process of the liquid filler spreading out and making intimate contact with the base metal.

The chromium oxide layer acts as a barrier, preventing the filler metal from actually touching and bonding with the steel beneath. The filler will simply ball up and fail to flow, resulting in a weak or nonexistent joint.

Proven Methods for Brazing Stainless Steel

To create a strong brazed joint, the oxide layer must be removed and the surface kept clean during the heating process. There are two primary ways to accomplish this.

Method 1: Using a Brazing Flux

For torch brazing or induction brazing in open air, a chemical flux is required.

The flux is a chemical compound applied to the joint area before heating. It melts at a temperature below that of the filler metal, dissolving the chromium oxide layer and shielding the now-clean steel from re-oxidizing as it is heated.

Method 2: Controlled Atmosphere Furnace Brazing

For higher volume production or applications requiring maximum cleanliness, parts are brazed inside a sealed furnace. The air is removed and replaced with a specific atmosphere that manages the oxides.

Vacuum Brazing is a common technique where a powerful vacuum pump removes virtually all oxygen from the furnace. With no oxygen present, the oxide layer cannot form or re-form during the heating cycle, allowing the filler metal to wet the surface perfectly.

Hydrogen Brazing is another furnace method that uses a "reducing" atmosphere. The hydrogen gas actively reacts with and removes the chromium oxide from the steel's surface, leaving it perfectly clean for the brazing alloy.

Understanding the Trade-offs

Choosing between flux and furnace brazing depends entirely on your application, volume, and quality requirements. Neither method is universally superior.

Flux Brazing: Pros and Cons

This is the most accessible method, often done with a simple hand torch. It is ideal for repairs, one-off assemblies, and low-volume work.

The primary disadvantage is the risk of flux entrapment. If flux becomes trapped inside the finished joint, it can lead to corrosion over time. Thorough post-braze cleaning is mandatory to remove all residual flux, which can be difficult in complex geometries.

Furnace Brazing: Pros and Cons

This method produces extremely clean, high-integrity joints with excellent repeatability, making it ideal for critical applications and mass production. Since no flux is used, there is no risk of post-braze corrosion from entrapped chemicals.

The main drawback is the high capital cost and complexity of the equipment. Furnace brazing is a batch process that is not suitable for fieldwork or quick repairs.

Making the Right Choice for Your Goal

Your decision should be driven by the specific demands of your project.

- If your primary focus is a simple prototype or a one-off repair: Use a high-quality black brazing flux designed specifically for stainless steel and a standard torch.

- If your primary focus is high-volume production or aerospace-grade quality: Furnace brazing in a vacuum or a reducing atmosphere is the correct choice for its cleanliness and repeatability.

- If your primary focus is joining stainless steel to another metal (like copper): Brazing is an excellent method, but the rule remains the same—you must use a flux or atmosphere that can manage the stainless steel's oxide layer.

Success in brazing stainless steel comes down to selecting the right technique to manage its protective oxide layer for the duration of the heating process.

Summary Table:

| Brazing Method | Key Mechanism | Best For | Key Consideration |

|---|---|---|---|

| Flux Brazing | Chemical flux dissolves oxide layer and prevents re-oxidation. | Prototypes, repairs, low-volume work. | Risk of flux entrapment; requires thorough cleaning. |

| Furnace Brazing | Vacuum or hydrogen atmosphere removes oxygen, preventing oxide formation. | High-volume production, critical/aerospace applications. | High equipment cost; not suitable for fieldwork. |

Need to Braze Stainless Steel for Your Laboratory Application?

Brazing stainless steel components for your lab equipment requires precision and the right technique to ensure joint integrity and prevent corrosion. KINTEK specializes in providing the lab equipment and expert support needed for successful thermal processing.

We can help you:

- Select the optimal brazing method for your specific stainless steel alloy and application.

- Source reliable furnaces and accessories for controlled atmosphere brazing.

- Achieve clean, strong, and repeatable joints for your critical laboratory assemblies.

Contact our experts today to discuss your project and ensure your brazing process is a success.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is the purpose of performing high vacuum heating treatment on titanium substrates? Ensure Superior Coating Adhesion

- How do you maintain a hot zone vacuum furnace? Extend Lifespan and Ensure Process Quality

- What type of brazing works at lower temperature? Silver Alloys for Heat-Sensitive Materials

- What is vacuum heat treatment process? Achieve Superior Control, Cleanliness, and Quality

- What is the function of a vacuum oven in fluorinated graphene electrode sheets? Enhance Battery Performance & Safety

- What temperature is brazing copper? Master the Heat for Perfect Joints

- What is the purpose of radiation as a heat transfer? Achieve Non-Contact Heating in a Vacuum

- What are the advantages of using a vacuum brazing furnace for TLP bonding? Achieve Superior Joint Integrity