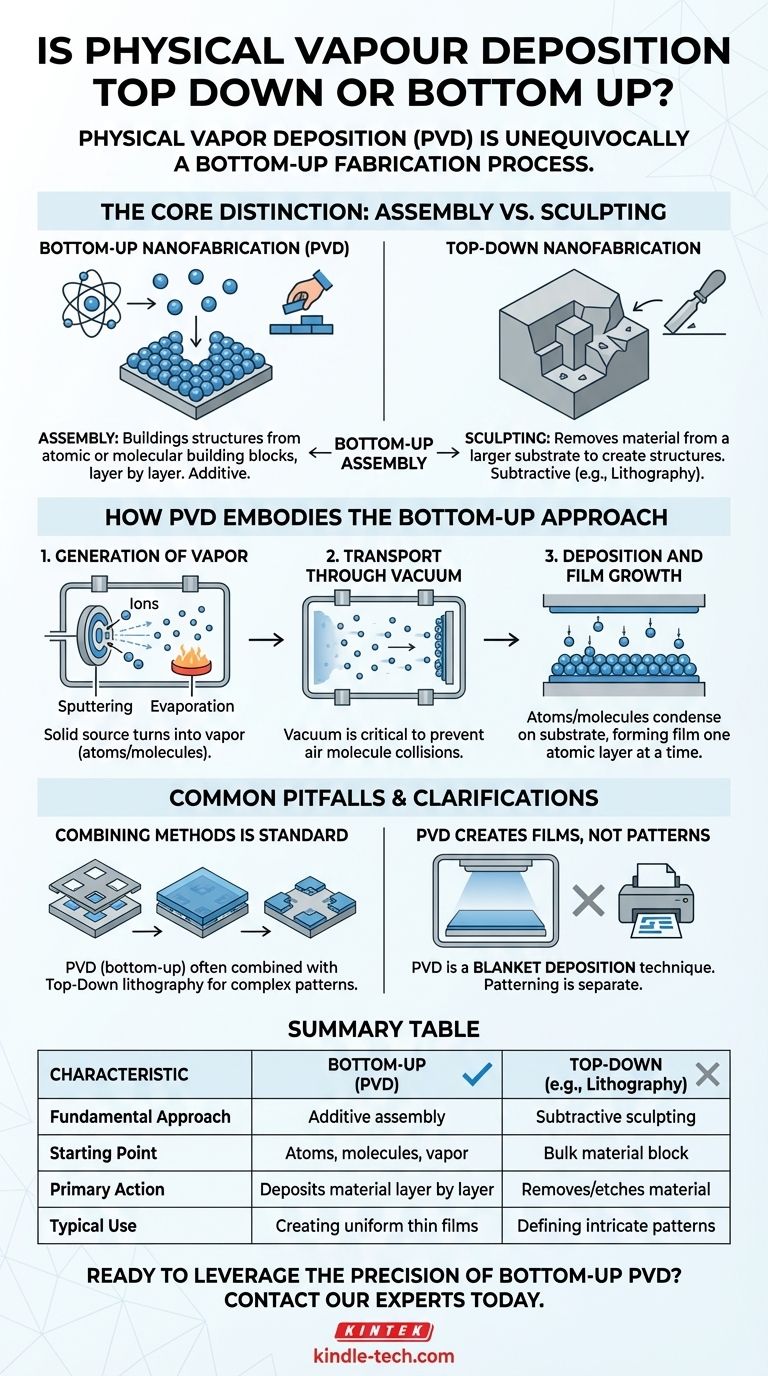

To be clear: Physical Vapor Deposition (PVD) is unequivocally a bottom-up fabrication process. This classification comes from its fundamental mechanism, which involves building a material layer by layer from its most basic constituents—atoms or molecules—rather than carving a structure out of a larger block.

The core distinction is one of strategy: bottom-up techniques like PVD assemble structures from atomic or molecular building blocks, while top-down techniques sculpt structures by removing material from a larger substrate.

The Core Principle: Assembly vs. Sculpting

To understand why PVD fits where it does, it's crucial to grasp the two fundamental approaches to nanofabrication.

Defining "Bottom-Up" Nanofabrication

Bottom-up fabrication starts with the smallest possible units—atoms, molecules, or clusters—and systematically assembles them into a larger, more complex structure.

Think of it as building a wall with individual bricks. Each brick (an atom) is placed precisely to create the final, desired form (the thin film). This method is additive by nature.

Defining "Top-Down" Nanofabrication

Top-down fabrication takes the opposite approach. It begins with a large piece of bulk material and uses subtractive processes, like carving or etching, to remove material until only the desired structure remains.

This is analogous to a sculptor starting with a block of marble and chipping away everything that isn't the final statue. Photolithography, the cornerstone of the semiconductor industry, is the classic example.

How PVD Embodies the Bottom-Up Approach

The PVD process is a perfect illustration of the bottom-up, or additive, manufacturing principle. It generally consists of three key stages.

1. Generation of Vapor

A solid source material, known as the "target," is converted into a vapor of individual atoms or molecules. This is typically achieved through sputtering (bombarding the target with energetic ions) or thermal evaporation (heating the material until it vaporizes).

2. Transport Through Vacuum

These vaporized particles travel through a low-pressure vacuum chamber from the source to the target object, known as the "substrate." The vacuum is critical to prevent these particles from colliding with air molecules.

3. Deposition and Film Growth

The atoms or molecules land on the substrate's surface and condense, forming a thin, solid film. The film grows in thickness one atomic layer at a time as more particles arrive, perfectly embodying the "building with bricks" analogy.

Common Pitfalls and Clarifications

Understanding the distinction is key, but it's also important to recognize how these methods are used in practice.

Combining Methods is Standard Practice

In real-world applications, especially semiconductor manufacturing, bottom-up and top-down techniques are almost always used together. PVD is not used in isolation to create complex patterns.

For example, to create metal wiring on a chip, a top-down lithography step first creates a patterned mask. Then, a bottom-up PVD step deposits a layer of metal over the entire surface. Finally, another process (like "lift-off" or etching) removes the unwanted metal, leaving behind the desired circuit pattern.

PVD Creates Films, Not Patterns

A common point of confusion is thinking PVD "prints" patterns. It does not. PVD is a blanket deposition technique that coats everything in its line of sight. The patterning and intricate shaping are handled by the top-down lithography and etching steps that precede or follow it.

Applying This to Your Goal

Your understanding of this concept directly impacts how you would approach a fabrication challenge.

-

If your primary focus is creating a uniform, high-purity thin film: You are using a pure bottom-up method. PVD is the ideal tool for depositing materials with precise, atomic-level control over thickness and composition.

-

If your primary focus is fabricating a complex micro-scale device (like a transistor): You will use a combination of approaches. You'll rely on top-down photolithography to define the pattern and bottom-up PVD to deposit the functional material layers within that pattern.

-

If your primary focus is controlling material properties at the nanoscale: The bottom-up nature of PVD is your advantage. By controlling deposition parameters, you directly influence the film's crystal structure, density, and stress at the atomic level.

Understanding the distinction between bottom-up assembly and top-down sculpting is fundamental to mastering modern fabrication.

Summary Table:

| Characteristic | Bottom-Up (PVD) | Top-Down (e.g., Lithography) |

|---|---|---|

| Fundamental Approach | Additive assembly | Subtractive sculpting |

| Starting Point | Atoms, molecules, vapor | Bulk material block |

| Primary Action | Deposits material layer by layer | Removes/etches material |

| Typical Use | Creating uniform thin films | Defining intricate patterns |

Ready to leverage the precision of bottom-up PVD in your lab? KINTEK specializes in high-performance lab equipment and consumables for all your deposition needs. Whether you're depositing uniform thin films or integrating PVD into a larger fabrication process, our expertise ensures you achieve superior material control and consistent results. Contact our experts today to discuss how our solutions can enhance your laboratory's capabilities!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- How does plasma vapor deposition work? A Low-Temperature Coating Solution for Sensitive Materials

- What is the difference between PECVD and sputter? Choose the Right Thin-Film Deposition Method

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the uses of PECVD? A Guide to Low-Temperature Thin-Film Deposition