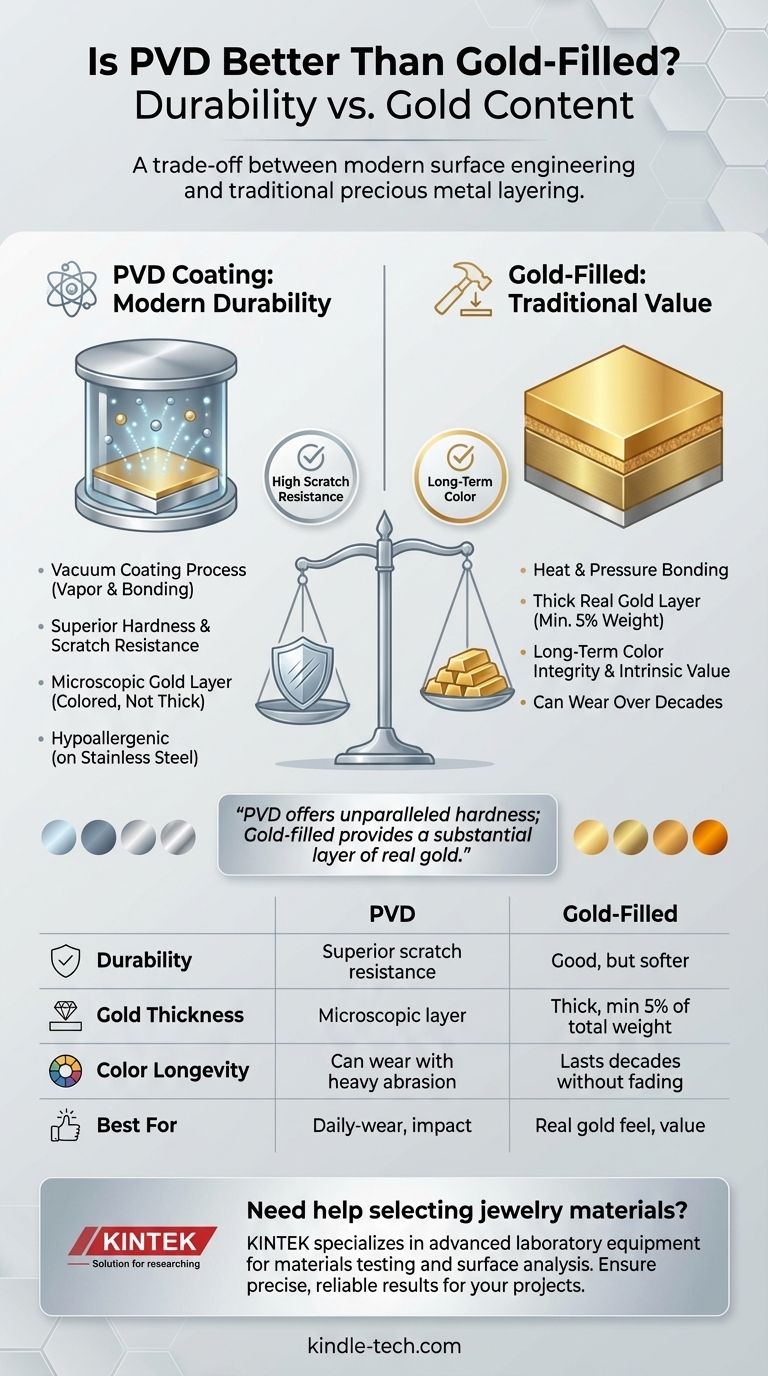

For durability and scratch resistance, PVD is better. However, for a thicker layer of real gold and long-term color integrity, gold-filled is superior. The "better" choice depends entirely on whether your priority is surface hardness or precious metal content.

Choosing between PVD and gold-filled jewelry is a trade-off between modern surface engineering and traditional precious metal layering. PVD offers unparalleled hardness and resistance to scratches, while gold-filled provides a substantial layer of real gold that resists wear over many years.

What is PVD Coating?

Physical Vapor Deposition (PVD) is a modern vacuum coating process that bonds a very thin but extremely durable film to a base metal, most commonly stainless steel. It represents a technological approach to surface finishing.

The Process: Vapor and Bonding

In a vacuum chamber, a solid material (like titanium or other durable compounds) is vaporized into its atomic particles. A high-voltage current then directs these particles to bond with the surface of the jewelry, creating a seamless, integrated coating.

Key Benefit: Superior Hardness

The primary advantage of PVD is its exceptional hardness and wear resistance. Based on the principles from microchip and medical device manufacturing, these coatings are designed to resist corrosion, scratches, and high temperatures far better than traditional plating methods.

The Role of Gold in PVD

A PVD finish can be colored to look like yellow or rose gold. While it can use real gold in the coating process, the layer is microscopic. The durability comes from the hard compound material itself (like titanium nitride), not from the thickness of the gold.

What is Gold-Filled?

Gold-filled is a legally regulated term that refers to a traditional method of bonding a thick layer of real gold to a base metal core, typically jeweler's brass. It represents a value-based approach centered on precious metal content.

The Process: Heat and Pressure

To create gold-filled material, a solid layer of gold is bonded to a brass core using intense heat and pressure. This is a mechanical bond, not a plating or coating. By law, the gold must constitute at least 5% (or 1/20) of the total item weight.

Key Benefit: A Thick Gold Layer

This 5% minimum results in a layer of gold that is 50 to 100,000 times thicker than most gold plating and significantly thicker than the color layer in PVD. It can be worn daily for years or even decades without the gold wearing through to the base metal.

How It Wears Over Time

Because the outer layer is thick, solid gold, it wears just like a solid gold piece would. It will not fade or have its color rub off. With extreme and prolonged abrasion, the gold can eventually wear thin, but this takes a very long time.

Understanding the Trade-offs

Neither option is universally superior; they excel in different areas. Your choice depends on understanding their core strengths and weaknesses.

Durability and Scratch Resistance

PVD is the clear winner here. The vacuum-bonded coating is significantly harder than the surface of gold-filled jewelry. For items like watches or bracelets that see frequent impact, PVD provides better protection against scratches and dings.

Longevity of Gold Color

Gold-filled is superior for color longevity. With a much thicker layer of real gold, it is highly unlikely to ever wear through to the base metal with normal use. The color of a PVD coating, while durable, is microscopically thin and can eventually be scratched off with heavy wear, revealing the steel underneath.

Intrinsic Value

Gold-filled jewelry has more intrinsic value due to its significant real gold content. PVD's value is derived from its advanced manufacturing process and performance characteristics, not its precious metal content.

Hypoallergenic Properties

This often depends on the base metal. PVD is typically applied to surgical-grade stainless steel, which is highly hypoallergenic. Gold-filled uses a brass core, and if the gold layer were to wear through after many years, the brass could cause a reaction in people with sensitive skin.

Making the Right Choice for Your Goal

Ultimately, the best choice aligns with your lifestyle and what you value most in a piece of jewelry.

- If your primary focus is maximum scratch resistance: Choose PVD, especially for daily-wear items like watches or rings that are exposed to harsh contact.

- If your primary focus is the feel and long-term color of real gold: Choose gold-filled for its thick, durable layer of precious metal that will not fade.

- If you have very sensitive skin: PVD on a stainless steel base is generally the safest bet against skin irritation.

By understanding the difference between surface hardness and precious metal content, you can confidently select the jewelry that best meets your needs.

Summary Table:

| Feature | PVD Coating | Gold-Filled |

|---|---|---|

| Durability | Superior scratch resistance | Good durability, but softer surface |

| Gold Layer Thickness | Microscopic layer | Thick, legally required 5% of total weight |

| Color Longevity | Can wear off with heavy abrasion | Lasts for decades without fading |

| Intrinsic Value | Advanced manufacturing process | Significant real gold content |

| Best For | Daily-wear items exposed to impact | Jewelry where real gold feel matters |

Need help selecting the right jewelry materials for your project? At KINTEK, we specialize in providing advanced laboratory equipment and consumables for materials testing and surface analysis. Whether you're developing new coatings or testing precious metal alloys, our solutions help you achieve precise, reliable results. Contact our experts today to discuss how we can support your jewelry manufacturing or materials research needs!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition