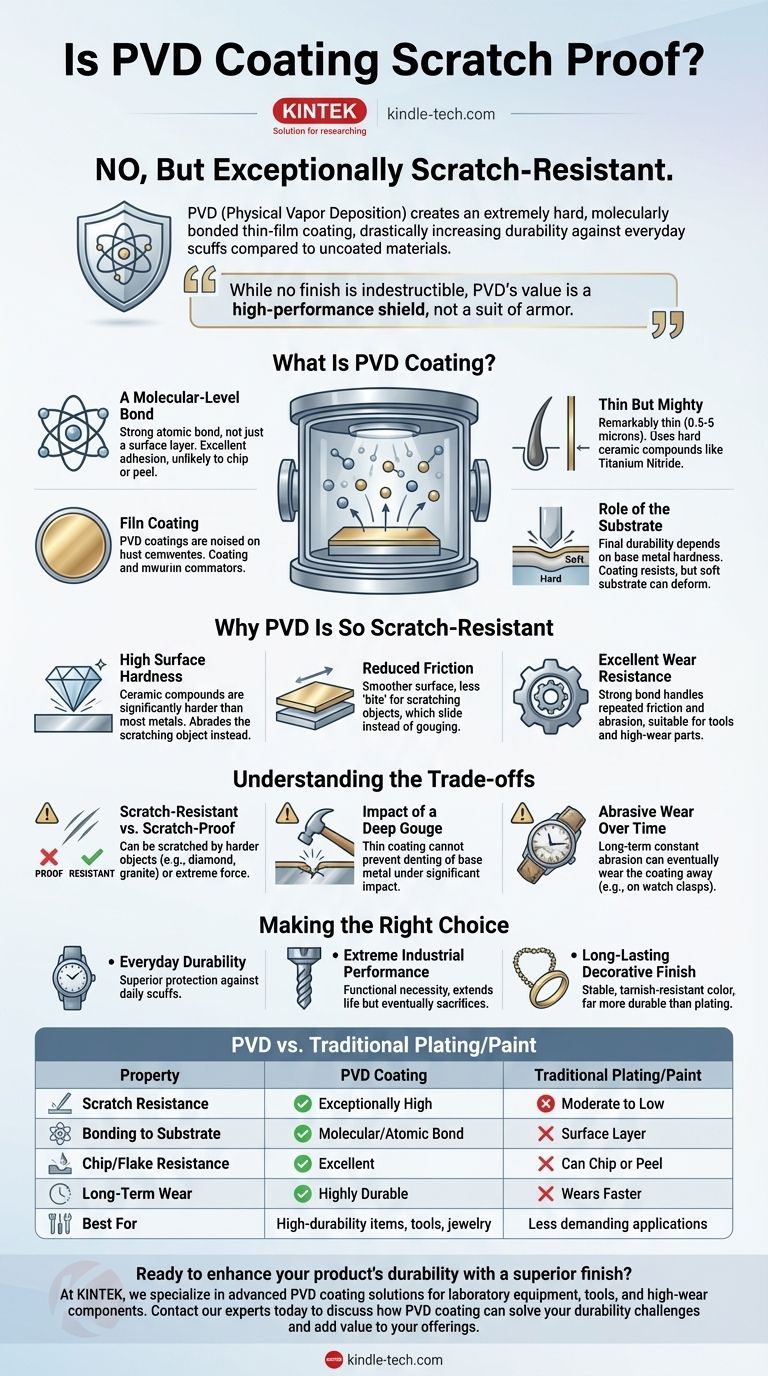

No, PVD coating is not scratch-proof, but it is exceptionally scratch-resistant. The process of Physical Vapor Deposition (PVD) creates an extremely hard, thin-film coating that molecularly bonds to the surface of a metal. This provides a dramatic increase in durability against the scuffs and scrapes of everyday use compared to an uncoated or traditionally plated material.

While no finish is truly indestructible, PVD's value lies in its ability to create a surface that is significantly harder and more durable than the underlying metal. True understanding comes from seeing it as a high-performance shield that resists damage, not a suit of armor that makes an object invincible.

What Is PVD Coating?

Physical Vapor Deposition is an advanced vacuum coating process. It works by vaporizing a solid material in a vacuum and depositing it, one atom or molecule at a time, onto the surface of a substrate.

A Molecular-Level Bond

Unlike paint or traditional plating, PVD coating is not just a layer sitting on top of the metal. The process creates a strong, atomic bond between the coating and the substrate.

This results in a finish that has excellent adhesion and is highly unlikely to chip, flake, or peel.

Thin But Mighty

PVD coatings are remarkably thin, typically ranging from 0.5 to 5 microns (a human hair is about 70 microns thick).

Despite being so thin, the specific materials used—often hard ceramic compounds like Titanium Nitride—give the surface its powerful new properties without altering the part's dimensions or texture.

The Role of the Substrate

The final durability of a PVD-coated object is heavily dependent on the hardness of the base metal it's applied to.

A hard PVD coating on a soft metal like aluminum will still allow the object to dent under impact. The coating itself will resist scratching, but the underlying material can deform, compromising the coating in that spot.

Why PVD Is So Scratch-Resistant

The impressive durability of PVD comes from a combination of three key physical properties.

A Dramatic Increase in Hardness

The primary reason PVD is so resistant to scratches is its high surface hardness. The ceramic compounds used for the coating are significantly harder than most metals, including stainless steel.

When a less-hard object attempts to scratch the surface, it is the object itself that is more likely to be abraded, not the PVD coating.

Reduced Friction

PVD coatings create a smoother, lower-friction surface. This means that when an object scrapes across it, there is less "bite."

Instead of digging in and creating a gouge, the object is more likely to slide harmlessly across the surface, leaving no mark.

Excellent Wear Resistance

Because the coating is bonded so tightly to the substrate, it stands up exceptionally well to repeated friction and abrasive wear over long periods.

This is why PVD is not only used for decorative items like watches and jewelry but also for high-performance industrial applications like machine cutting tools, which operate under intense friction and heat.

Understanding the Trade-offs

Building trust means being objective. It is critical to understand that even PVD has its limits.

Scratch-Resistant vs. Scratch-Proof

The distinction is crucial. A PVD coating can and will be scratched by an object that is harder than the coating itself or by an object applied with extreme force.

For example, a sharp edge of a diamond, sapphire crystal, or piece of granite can certainly scratch a PVD finish.

The Impact of a Deep Gouge

PVD coatings are thin. They cannot protect the base metal from denting or deforming under a significant impact.

If you drop a PVD-coated watch on concrete, the steel case may dent. The PVD coating in the impacted area will be damaged along with the metal beneath it.

Abrasive Wear Over Time

While highly resistant, the coating can eventually be worn away by constant, long-term abrasion.

On a watch bracelet, for example, the areas that constantly rub against a desk—such as the corners of the clasp—may show signs of wear after several years of daily use.

Making the Right Choice for Your Goal

The decision to choose a PVD-coated product depends entirely on your performance expectations.

- If your primary focus is everyday durability for items like watches, jewelry, or faucets: PVD is an outstanding choice that provides superior protection against the minor scuffs and scratches of daily life.

- If your primary focus is extreme industrial performance for tools: PVD is a functional necessity that significantly extends tool life, but it should be viewed as a sacrificial layer that will eventually wear and may require recoating.

- If your primary focus is a long-lasting decorative finish: PVD provides a stable, tarnish-resistant color that is far more durable than other coloring methods, making it ideal for lasting aesthetic appeal.

Ultimately, viewing PVD as a high-performance shield for your material, rather than an indestructible suit of armor, is the key to understanding its true value.

Summary Table:

| Property | PVD Coating | Traditional Plating/Paint |

|---|---|---|

| Scratch Resistance | Exceptionally High | Moderate to Low |

| Bonding to Substrate | Molecular/Atomic Bond | Surface Layer |

| Chip/Flake Resistance | Excellent | Can Chip or Peel |

| Long-Term Wear | Highly Durable | Wears Faster |

| Best For | High-durability items, tools, jewelry | Less demanding applications |

Ready to enhance your product's durability with a superior finish?

At KINTEK, we specialize in advanced PVD coating solutions for laboratory equipment, tools, and high-wear components. Our coatings provide the exceptional scratch and wear resistance your products need to last longer and perform better.

Contact our experts today to discuss how PVD coating can solve your durability challenges and add value to your offerings.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance