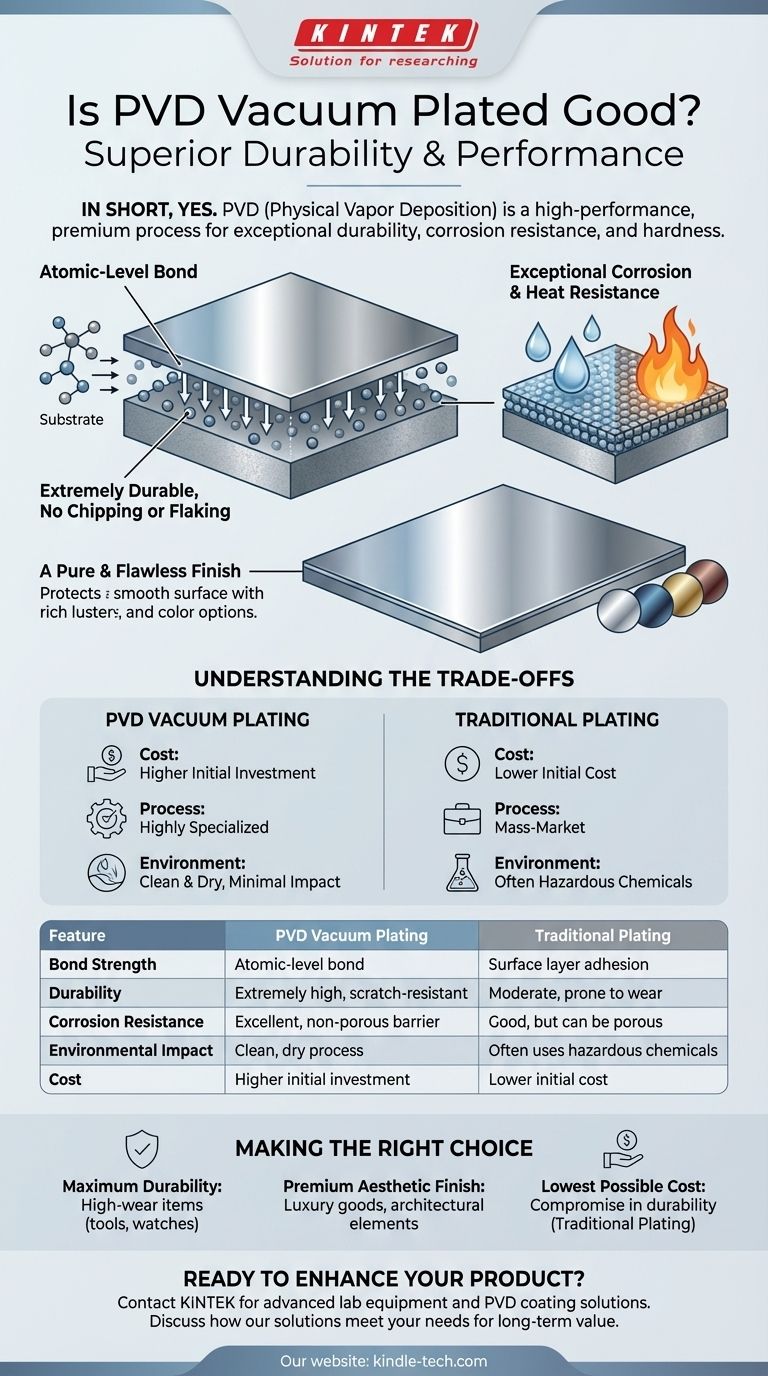

In short, yes. PVD (Physical Vapor Deposition) is an exceptionally good coating technology, widely regarded as a high-performance, premium process. It creates a finish that is significantly more durable, corrosion-resistant, and harder than traditional plating methods. This is because PVD forms a powerful, atomic-level bond with the surface of the base material rather than simply layering a coat on top.

While many coating methods simply apply a surface layer, PVD fundamentally alters the properties of the surface itself. It is a process where you trade higher initial cost for vastly superior durability, long-term performance, and environmental safety compared to conventional alternatives.

What Makes PVD a Superior Coating Technology?

The "goodness" of PVD comes from the physics of its application process. By depositing material vapor in a high-vacuum environment, it creates a bonded layer with unique characteristics.

An Atomic-Level Bond for Extreme Durability

Unlike electroplating, which adheres a layer on top of a substrate, PVD integrates the coating material with the substrate at a molecular level.

This creates an incredibly strong bond that is not prone to chipping or flaking. The materials used, such as titanium nitride, are inherently hard, resulting in a finish that is highly resistant to scratches and wear.

Exceptional Corrosion and Heat Resistance

The PVD coating creates a dense, non-porous barrier that seals the base material from the environment.

This provides powerful protection against oxidation, tarnish, and corrosion. Furthermore, these coatings are able to withstand significantly higher temperatures than paint or traditional plating.

A Pure and Flawless Finish

Because the process occurs in a vacuum, the coating is extremely pure and free from contaminants that can cause imperfections.

The result is a smooth, fine surface with a rich metallic luster that is difficult to achieve with other methods. This also allows for a wide range of consistent and repeatable color choices.

Understanding the Trade-offs

No technology is perfect for every application. To make an informed decision, you must understand the limitations of PVD.

The Matter of Cost

The primary drawback of PVD is its cost. The process requires complex, specialized vacuum chamber equipment and is slower than mass-market methods like electroplating.

This higher upfront investment makes PVD better suited for products where performance and longevity are critical priorities that justify the expense.

The Process is Highly Specialized

PVD is not a simple dipping process. It requires a controlled environment, including a reliable cooling system and routine maintenance of the machinery.

This operational complexity contributes to both the cost and the high quality of the final product. It is a high-tech solution for applications that demand high-tech results.

An Environmentally Conscious Choice

A significant advantage of PVD is its minimal environmental impact. Unlike electroplating, which often involves hazardous chemicals and produces toxic waste, PVD is a clean, dry vacuum process.

This makes it the responsible choice for manufacturers and consumers focused on sustainability.

Making the Right Choice for Your Goal

PVD is a superior technology, but its suitability depends entirely on your project's priorities.

- If your primary focus is maximum durability and longevity: PVD is the definitive choice for high-wear items like tools, watches, medical devices, or high-end hardware.

- If your primary focus is a premium aesthetic finish: PVD provides a flawless, long-lasting decorative surface that justifies its cost for luxury goods and architectural elements.

- If your primary focus is the lowest possible cost: Traditional electroplating or painting may be more economical, but you must accept the significant compromise in durability and wear resistance.

Ultimately, choosing PVD is an investment in unparalleled performance and a finish that is engineered to last.

Summary Table:

| Feature | PVD Vacuum Plating | Traditional Plating |

|---|---|---|

| Bond Strength | Atomic-level bond | Surface layer adhesion |

| Durability | Extremely high, scratch-resistant | Moderate, prone to wear |

| Corrosion Resistance | Excellent, non-porous barrier | Good, but can be porous |

| Environmental Impact | Clean, dry process | Often uses hazardous chemicals |

| Cost | Higher initial investment | Lower initial cost |

Ready to enhance your product's durability and finish with PVD technology? KINTEK specializes in advanced lab equipment and consumables, including PVD coating solutions tailored for laboratory and industrial applications. Our expertise ensures you get a coating that is engineered to last, providing superior wear resistance and a flawless aesthetic. Contact us today to discuss how our PVD solutions can meet your specific needs and deliver long-term value for your projects.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition