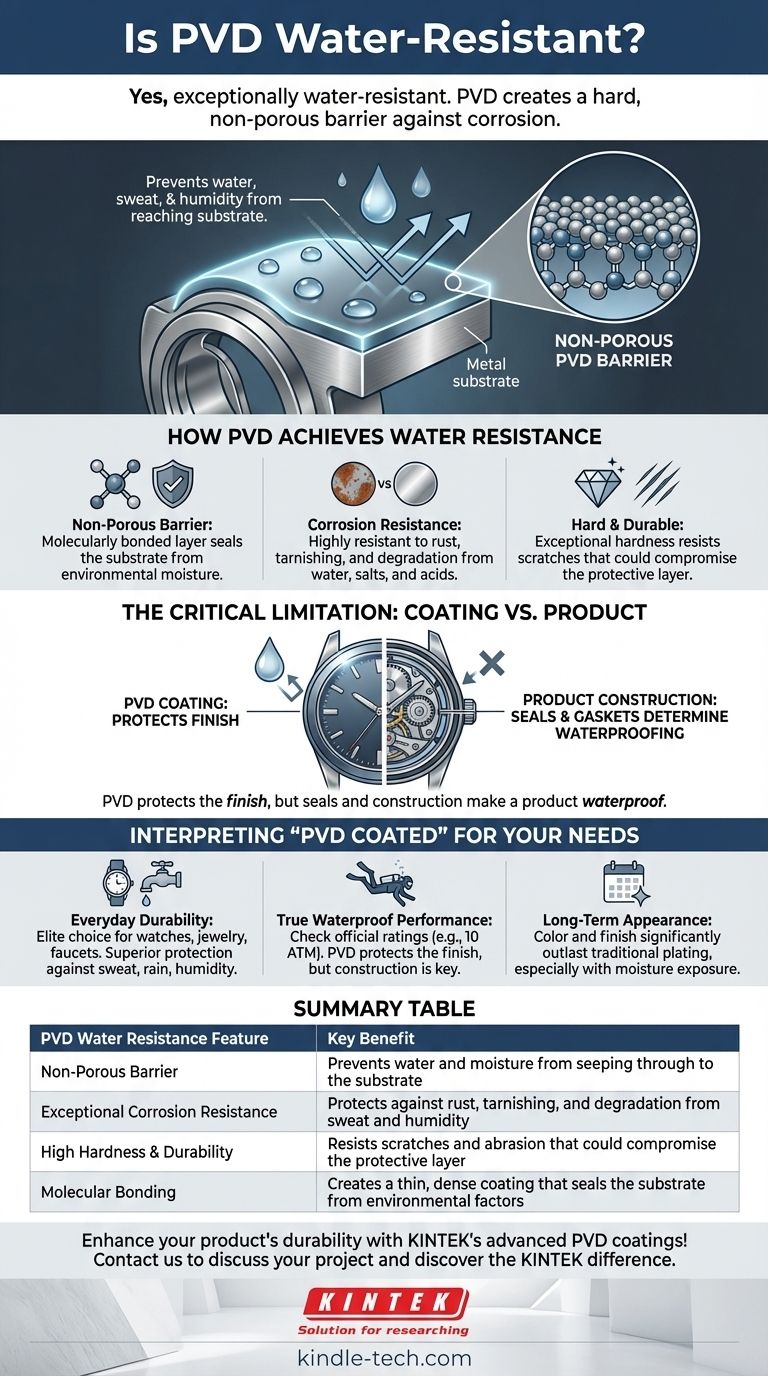

Yes, PVD is exceptionally water-resistant. Physical Vapor Deposition (PVD) coatings create a very hard, dense, and non-porous barrier on the surface of an object. This barrier is highly resistant to corrosion, meaning it effectively prevents water, sweat, and humidity from reaching and reacting with the underlying metal.

The core function of a PVD coating is not to make a product waterproof, but to make its finish incredibly durable and resistant to corrosion caused by water and other environmental factors.

How PVD Achieves Water Resistance

The term "water-resistant" in the context of coatings refers to its ability to prevent corrosion, tarnishing, and degradation when exposed to moisture. PVD excels at this.

It Creates a Protective, Non-Porous Barrier

A PVD coating is molecularly bonded to the base material, known as the substrate. This process creates an incredibly thin but dense layer with no pores for water to seep through.

This layer effectively seals the substrate from the outside environment, including moisture.

The Key is Corrosion Resistance

The primary way water damages metal is through corrosion, such as rust or tarnishing. The references highlight that PVD coatings are highly resistant to corrosion.

This means the coating itself does not react with water, salts, or acids commonly found in sweat and the atmosphere. By preventing this chemical reaction, it keeps the product's finish pristine.

It's Physically Hard and Durable

PVD coatings are known for their exceptional hardness and resistance to scratches and abrasion.

This physical toughness is critical for water resistance. It ensures the protective barrier doesn't easily scratch or wear off, which would expose the vulnerable metal underneath to moisture.

Understanding the Critical Limitation

While the coating is water-resistant, it's crucial to distinguish between the coating's properties and the overall product's design.

The Coating vs. The Complete Product

A PVD-coated watch case is highly protected against corrosion from sweat or rain. However, the PVD coating does not make the watch itself waterproof.

The waterproof capability of a watch depends on its construction—the seals, gaskets, and crown assembly. The coating protects the finish, while the gaskets keep water out of the internal mechanism.

The Substrate Still Matters

PVD provides a powerful shield, but it is a very thin layer. If the coating is compromised by a deep gouge or impact that exposes the substrate metal, that exposed area can then corrode.

Fortunately, due to its extreme hardness, significantly damaging a quality PVD coating is difficult to do through normal wear.

How to Interpret "PVD Coated" for Your Needs

- If your primary focus is everyday durability (watches, jewelry, faucets): PVD is an elite choice. It provides superior protection against corrosion from handwashing, sweat, rain, and humidity, ensuring the finish remains vibrant for years.

- If your primary focus is true waterproof performance (dive watches, marine hardware): Look for the product's official water resistance rating (e.g., 10 ATM, IP68). The PVD coating is a valuable feature that protects the finish, but the product's construction is what makes it truly waterproof.

- If your primary focus is long-term appearance: PVD's combination of corrosion and scratch resistance means the color and finish will dramatically outlast traditional plating, especially when regularly exposed to moisture.

Ultimately, a PVD coating provides your product's finish with elite-level armor against the corrosive effects of water.

Summary Table:

| PVD Water Resistance Feature | Key Benefit |

|---|---|

| Non-Porous Barrier | Prevents water and moisture from seeping through to the substrate |

| Exceptional Corrosion Resistance | Protects against rust, tarnishing, and degradation from sweat and humidity |

| High Hardness & Durability | Resists scratches and abrasion that could compromise the protective layer |

| Molecular Bonding | Creates a thin, dense coating that seals the substrate from environmental factors |

Enhance your product's durability with KINTEK's advanced PVD coatings!

Whether you're manufacturing watches, jewelry, faucets, or marine hardware, our PVD solutions provide elite-level armor against water, sweat, and corrosion—ensuring long-lasting finishes that stand up to daily wear.

As a specialist in lab equipment and consumables, KINTEK delivers precision coatings tailored to your specific needs. Let us help you protect your products and impress your customers.

Contact us today to discuss your project and discover the KINTEK difference!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Vacuum Cold Trap Direct Cold Trap Chiller

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

People Also Ask

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating