The sustainability of plastic pyrolysis is highly conditional and a subject of intense debate. While it is often presented as a modern solution for plastic waste, its true environmental credentials depend heavily on the specific technology used, the type and cleanliness of the plastic feedstock, and how the energy and material outputs are managed. In the best-case scenario, the process can be energy-efficient by using its own outputs to power the operation, but this ideal is not always met in practice.

While plastic pyrolysis offers a potential route for managing non-recyclable waste, its claim to sustainability is fragile. The process is energy-intensive and its environmental benefits hinge entirely on operational efficiency and whether its products are used for true circularity or simply burned as a low-grade fuel.

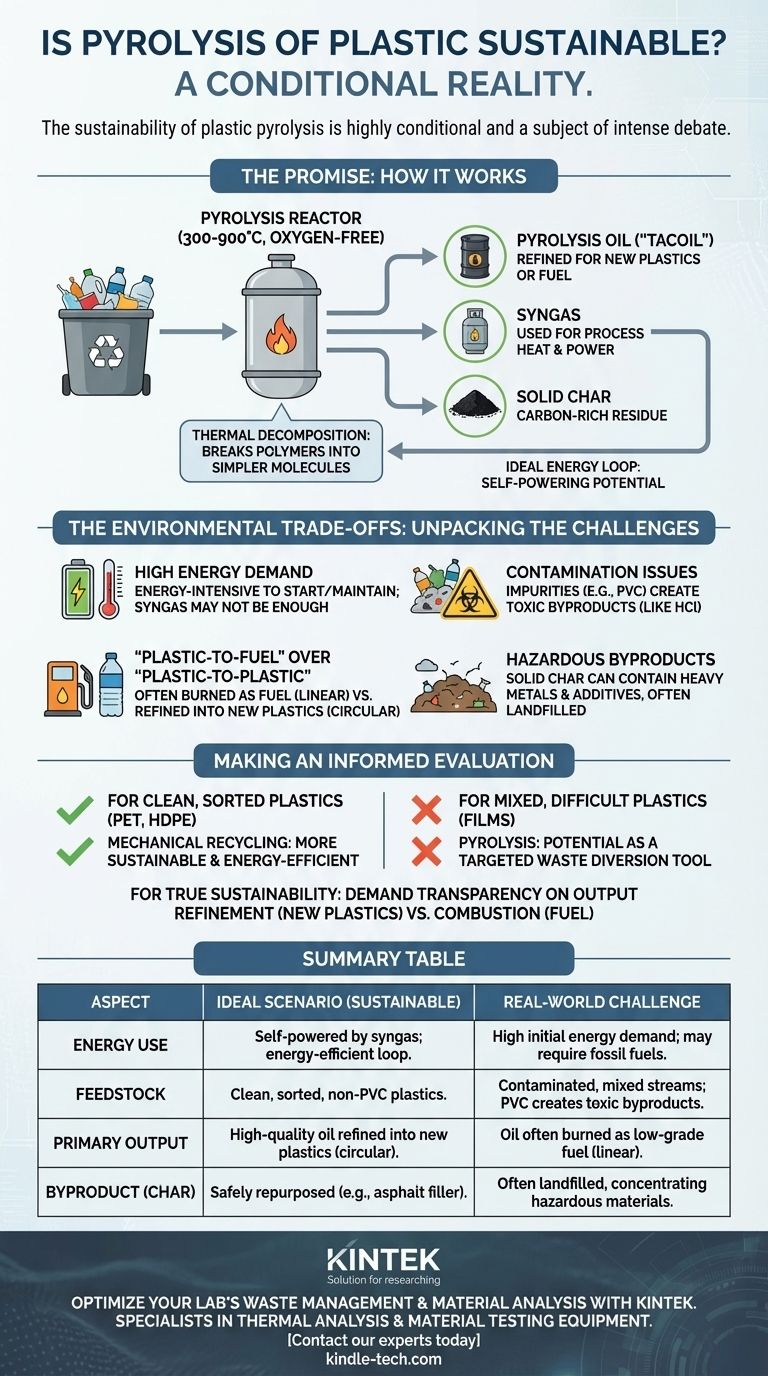

The Promise: How Pyrolysis Aims for Sustainability

Plastic pyrolysis is a form of advanced, or chemical, recycling. It's designed to handle plastics that traditional mechanical recycling cannot.

The Core Process: Thermal Decomposition

Pyrolysis is the process of heating materials, like plastic, to high temperatures (300 to 900°C) in an oxygen-free environment.

Without oxygen, the material doesn't combust. Instead, the long polymer chains that make up plastic break down into smaller, simpler molecules.

The Intended Outputs

This process typically yields three main products:

- Pyrolysis Oil (or "Tacoil"): A synthetic crude oil that can be refined into new plastics or fuels.

- Syngas: A mixture of combustible gases (like hydrogen and methane) that can be used to generate heat and power for the pyrolysis plant itself.

- Solid Char: A carbon-rich solid residue, similar to charcoal.

The Ideal Energy Loop

The sustainability argument often centers on energy efficiency. The syngas produced can be burned to generate the heat required to run the pyrolysis furnace.

If this loop is efficient, the energy produced from the outputs can offset the energy required to run the process, making it appear self-sustaining. This is the core claim from which much of the sustainability narrative is built.

Unpacking the Environmental Trade-offs

The idealized vision of a self-powering, waste-eliminating system often clashes with real-world operational challenges. True sustainability requires looking beyond the basic chemical equation.

High Initial Energy Demand

Starting and maintaining a pyrolysis reactor at optimal temperature is an energy-intensive process. If the feedstock quality is poor or the system is inefficient, the energy generated from the syngas may not be enough to power the operation, requiring a constant input of external energy, often from fossil fuels.

The Challenge of Contamination

Plastic waste streams are rarely pure. Contaminants like food residue, paper, and different plastic types (especially PVC) can disrupt the process.

PVC, for example, releases chlorine, which creates highly corrosive and toxic hydrochloric acid, damaging equipment and creating hazardous byproducts that must be managed.

From "Plastic-to-Plastic" to "Plastic-to-Fuel"

The most sustainable outcome for pyrolysis is true "plastic-to-plastic" recycling, creating a circular economy. However, purifying pyrolysis oil to the high standard needed for new plastic production is complex and expensive.

As a result, a common and less sustainable pathway is to burn the oil as a fuel. This is essentially a form of energy recovery, not recycling. It converts a solid waste problem into an air emissions problem, releasing the carbon stored in the plastic into the atmosphere.

The Problem of Byproducts

The solid char byproduct is not always a benign material. It can contain heavy metals, toxic additives, and other contaminants from the original plastic waste.

Unless this char can be safely repurposed (e.g., as asphalt filler), it often ends up in a landfill, simply concentrating the hazardous materials from the original waste.

Making an Informed Evaluation

Pyrolysis is not a simple "good" or "bad" technology. It is a complex industrial process with specific applications and significant trade-offs that must be weighed against other waste management options like mechanical recycling and waste-to-energy incineration.

- If your primary focus is diverting difficult-to-recycle plastics (like films and mixed polymers) from landfills: Pyrolysis can be a viable tool, as mechanical recycling often cannot process these materials effectively.

- If your primary focus is minimizing carbon footprint and energy use: For clean, sorted plastic streams like PET bottles and HDPE jugs, mechanical recycling is almost always the more sustainable and energy-efficient choice.

- If your primary focus is creating a truly circular economy: Scrutinize any pyrolysis project's claims. Demand transparency on whether the output is being refined for new plastics ("plastic-to-plastic") or simply being burned as fuel.

Ultimately, viewing pyrolysis as a targeted industrial solution for specific waste problems, rather than a universal panacea for all plastic, is the first step toward making a responsible decision.

Summary Table:

| Aspect | Ideal Scenario (Sustainable) | Real-World Challenge |

|---|---|---|

| Energy Use | Self-powered by syngas; energy-efficient loop. | High initial energy demand; may require fossil fuel input. |

| Feedstock | Clean, sorted, non-PVC plastics. | Contaminated, mixed streams; PVC creates toxic byproducts. |

| Primary Output | High-quality oil refined into new plastics (circular). | Oil often burned as low-grade fuel (linear economy). |

| Byproduct (Char) | Safely repurposed (e.g., asphalt filler). | Often landfilled, concentrating hazardous materials. |

Ready to Optimize Your Lab's Waste Management or Material Analysis?

As you evaluate complex processes like pyrolysis, having the right equipment for accurate analysis is crucial. KINTEK specializes in high-quality lab equipment and consumables, providing the reliable tools you need for thermal analysis, material testing, and process development.

Whether you're researching alternative recycling methods or ensuring product quality, our solutions help you achieve precise, reproducible results. Let KINTEK be your trusted partner in advancing your laboratory's capabilities.

Contact our experts today to discuss how we can support your specific needs and drive your projects forward.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Muffle Oven Furnace for Laboratory

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Lab-Scale Vacuum Induction Melting Furnace

People Also Ask

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process