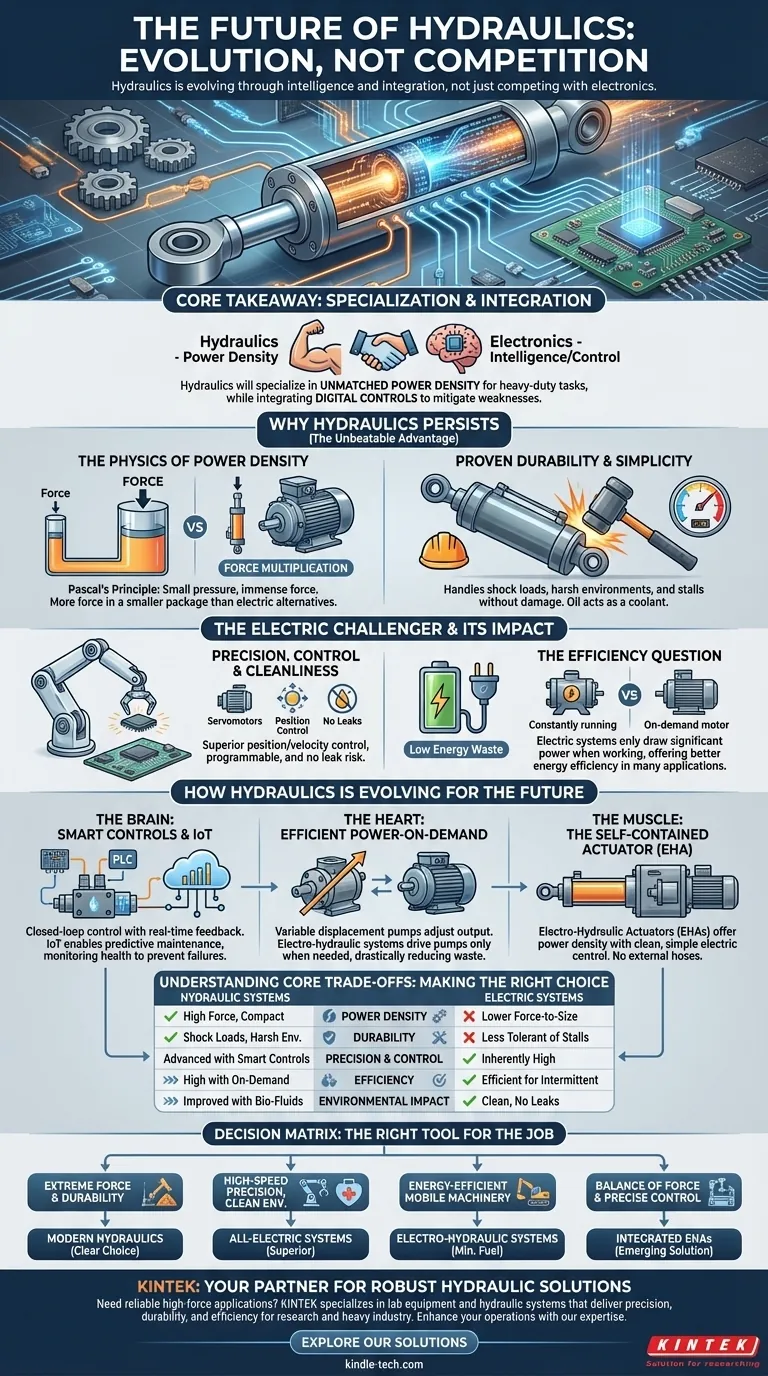

Yes, hydraulics has a robust future, but it will not look like its past. While the rapid advancement of electric actuation has led many to question its relevance, the fundamental physics of fluid power gives it an unmatched advantage in force and power density. This physical reality ensures that hydraulics will not be replaced, but rather that its role will become more specialized, intelligent, and integrated.

The core takeaway is that the future of hydraulics is not about competing with electric systems, but about evolving. Hydraulics will specialize in its core strength—unmatched power density for heavy-duty tasks—while integrating digital controls and electrification to mitigate its traditional weaknesses in efficiency and control.

The Unbeatable Advantage: Why Hydraulics Persists

To understand the future of hydraulics, we must first appreciate why it has dominated heavy industry for over a century. Its core value proposition is rooted in a simple principle of physics that electronics cannot replicate.

The Physics of Power Density

Hydraulic systems are masters of force multiplication. Based on Pascal's principle, a small amount of pressure applied to a contained fluid can generate immense force over a larger area.

This allows for the creation of actuators that are remarkably small and lightweight relative to the colossal forces they can exert. An electric motor and gearbox system capable of producing the same force would be significantly larger, heavier, and more complex.

Proven Durability and Simplicity

Hydraulic components like cylinders and pumps are mechanically simple and incredibly robust. They can withstand shock loads, operate in harsh environments, and tolerate stalls without damage—conditions that can destroy an electric motor or gearbox.

Oil also acts as a coolant, allowing hydraulic systems to dissipate heat effectively under continuous heavy loads.

The Electric Challenger and Its Impact

The rise of all-electric actuation is the primary driver of change. Electric systems have brought significant advantages that have forced the hydraulics industry to innovate.

Precision, Control, and Cleanliness

Servomotors offer superior position and velocity control right out of the box. Their movements are highly repeatable and easily programmable, making them ideal for high-speed, precision applications like robotics and packaging.

Furthermore, electric systems eliminate the risk of oil leaks, a critical advantage in sensitive environments like food processing or medical device manufacturing.

The Efficiency Question

A traditional, simple hydraulic circuit with a fixed-displacement pump can be notoriously inefficient. Much of the energy is converted into heat as oil is forced past relief valves or through throttling controls, especially when the actuator is idle or under partial load.

Electric systems, by contrast, only draw significant power when they are actively doing work, giving them a major efficiency advantage in many applications.

How Hydraulics is Evolving for the Future

The future of hydraulics is defined by its response to the challenges posed by electric systems. Modern hydraulics is becoming smarter, more efficient, and more integrated.

The Brain: Smart Controls and IoT

Modern hydraulic systems are increasingly equipped with sophisticated sensors and programmable logic controllers (PLCs). This allows for closed-loop control, where real-time feedback on pressure, flow, and position enables a level of precision that was previously impossible.

IoT integration also enables predictive maintenance, with sensors monitoring fluid condition, temperature, and vibration to alert operators to potential failures before they happen.

The Heart: Efficient Power-on-Demand

The inefficient, constantly-running pump is being replaced. Variable displacement pumps automatically adjust their output to match the exact flow and pressure required by the load at any given moment.

Even more advanced are electro-hydraulic systems, where a dedicated electric motor drives the pump. The motor can slow down or turn off completely when no power is needed, drastically reducing energy waste and approaching the efficiency of all-electric systems.

The Muscle: The Self-Contained Actuator

The lines are blurring with the rise of electro-hydraulic actuators (EHAs). These are integrated units that contain a cylinder, a compact pump, and a dedicated electric servomotor in a single, sealed package.

EHAs offer the best of both worlds: the extreme power density and robustness of hydraulics with the clean, precise, and simple control of an electric system. They eliminate the need for long hoses and a central power unit.

Understanding the Core Trade-offs

Choosing between hydraulic and electric systems is not about which is "better," but which is the right tool for a specific job.

Power Density

For applications requiring the highest possible force in the smallest possible space, hydraulics is the undisputed winner. This is its foundational advantage.

Energy Efficiency

For simple point-to-point motion with long idle times, all-electric systems often have the edge. However, for applications with heavy, sustained loads, a modern, power-on-demand hydraulic system can be highly efficient.

Control & Precision

For complex, high-speed motion profiles, electric servomotors generally offer more straightforward and precise control. Smart hydraulics with advanced feedback controls are closing this gap but often with more complexity.

Environmental Impact

Electric systems are inherently cleaner, with no risk of fluid leaks. However, the development of biodegradable and fire-resistant hydraulic fluids is mitigating this concern for many industries.

Durability and Overload Capacity

For handling unpredictable shock loads and stalls without damage, hydraulics remains superior. Its ability to absorb energy and relieve pressure provides a natural ruggedness.

Making the Right Choice for Your Application

Your decision must be driven by the primary demands of your task.

- If your primary focus is extreme force and durability: For applications like large presses, construction equipment, or mining machinery, modern hydraulics remains the clear and most cost-effective choice.

- If your primary focus is high-speed precision in a clean environment: For tasks like packaging, pick-and-place robotics, or medical automation, all-electric systems are almost always the superior solution.

- If your primary focus is energy-efficient mobile machinery: Look to the latest electro-hydraulic systems that combine electric drives with variable displacement pumps to minimize fuel consumption.

- If you need a balance of high force and precise control: Integrated electro-hydraulic actuators (EHAs) are the emerging solution, offering the power of hydraulics with the simple controls of electrics.

The future isn't a battle between oil and wires; it's about intelligently combining them to build more powerful, efficient, and capable machines.

Summary Table:

| Aspect | Hydraulic Systems | Electric Systems |

|---|---|---|

| Power Density | Unmatched for extreme force in compact spaces | Lower force-to-size ratio |

| Durability | Superior for shock loads and harsh environments | Less tolerant of stalls and overloads |

| Precision & Control | Advanced with smart controls and IoT integration | Inherently high out-of-the-box |

| Efficiency | High with modern power-on-demand systems | Efficient for intermittent tasks |

| Environmental Impact | Improved with biodegradable fluids | Clean, no risk of leaks |

Need a reliable solution for high-force applications? KINTEK specializes in lab equipment and consumables, serving laboratory needs with robust hydraulic systems that deliver precision, durability, and efficiency. Whether you're in research, manufacturing, or heavy industry, our expertise ensures you get the right equipment for your demanding tasks. Contact us today to explore how our hydraulic solutions can enhance your operations!

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Touchscreen Automatic Vacuum Heat Press

People Also Ask

- What is a sintering process? A Guide to Fusing Powders into High-Performance Parts

- What does a hydraulic heat press do? Achieve Industrial-Scale, Consistent Pressure for High-Volume Production

- What is a hot hydraulic press? Harness Heat and Pressure for Advanced Manufacturing

- How much force can a hydraulic press exert? Understanding its immense power and design limits.

- How is the pressure and temperature process used to make a synthetic diamond? Replicate Earth's Diamond Formation in a Lab