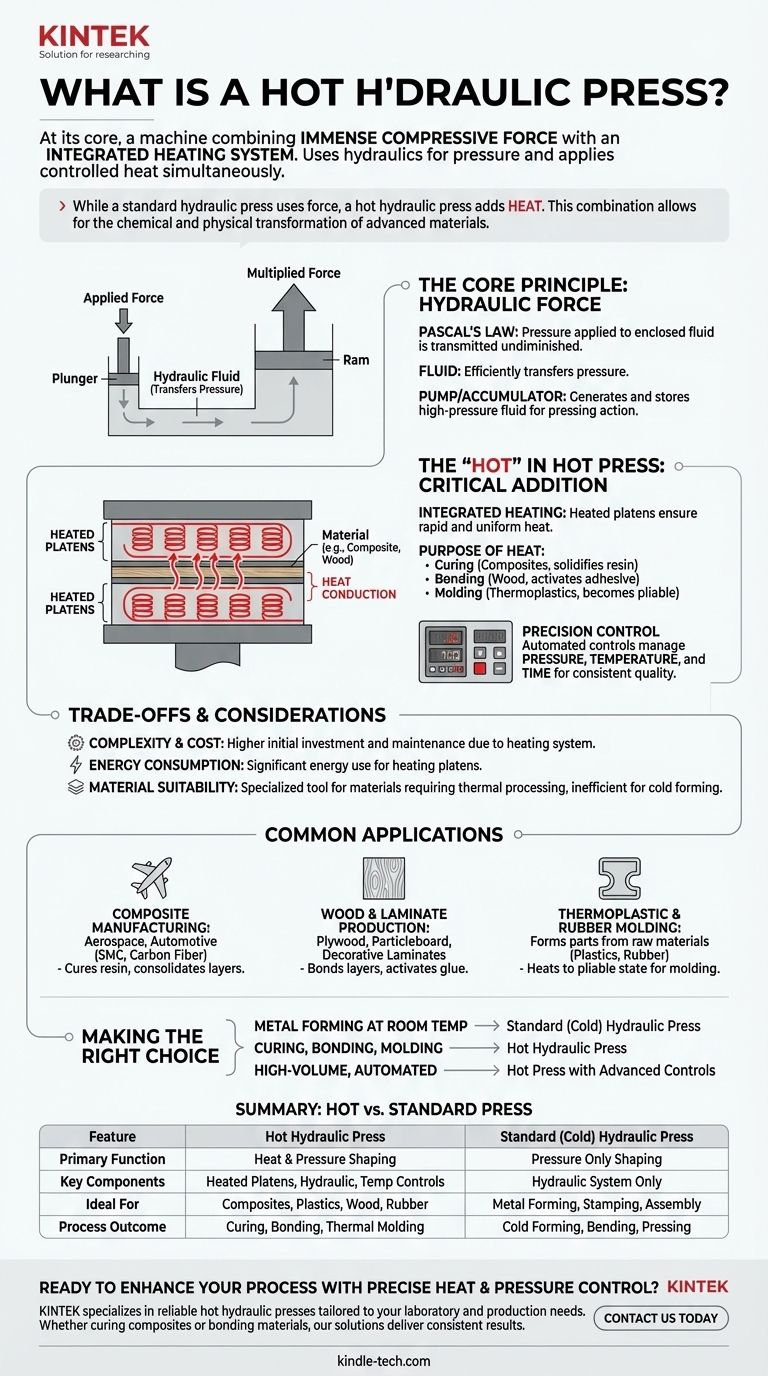

At its core, a hot hydraulic press is a machine that combines immense compressive force with an integrated heating system. It uses the principles of hydraulics to generate significant pressure, while simultaneously applying controlled heat to the material being processed. This dual-action capability makes it indispensable for manufacturing processes that require both pressure and thermal energy to shape, bond, or cure materials.

While a standard hydraulic press uses force to shape materials, a hot hydraulic press adds a critical second element: heat. This combination fundamentally changes the process, allowing for the chemical and physical transformation of advanced materials like composites, plastics, and wood products.

The Core Principle: How a Hydraulic Press Generates Force

A hot press is, first and foremost, a hydraulic press. Understanding its foundation in hydraulics is key to appreciating its power.

The Foundation: Pascal's Law

The machine operates on a principle known as Pascal's Law. This law states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

In a press, a small amount of force is applied to a small piston (the plunger), which pressurizes the hydraulic fluid (typically oil). This pressure is then transmitted to a much larger piston (the ram), multiplying the initial force significantly.

The Role of Hydraulic Fluid

The hydraulic fluid is the lifeblood of the system. Its primary job is not to be compressed, but to transfer pressure from the small plunger to the large ram efficiently and evenly.

The Mechanical Components

A pump pushes the fluid into the system. In some high-demand systems, a hydraulic accumulator stores this high-pressure fluid, releasing it rapidly when a strong, immediate thrust is needed. This force drives the ram, which performs the pressing action.

The "Hot" in Hot Press: The Critical Addition

The defining feature of a hot press is its ability to introduce heat into the pressing process. This is what separates it from a standard "cold" press.

Integrated Heating Systems

Hot presses are equipped with heated plates, known as platens. These platens typically contain a network of heating pipes or electrical elements that ensure rapid and uniform heat conduction across the entire surface of the material.

Why Heat Matters

The addition of heat is not arbitrary; it serves a specific purpose depending on the material.

- For composites (like carbon fiber), heat cures the resin matrix, solidifying the part.

- For wood products (like plywood), heat activates the adhesives that bond the layers together.

- For thermoplastics, heat brings the material to a pliable or molten state, allowing it to be molded into a new shape.

Precision Control

Modern hot presses feature automated control panels. These are critical for managing the three key variables of the process: pressure, temperature, and time. Precise control ensures consistent quality and repeatable results, which is vital in industrial manufacturing.

Understanding the Trade-offs and Considerations

While incredibly capable, a hot press introduces complexities and costs not present in a standard press.

Complexity and Cost

The integration of a heating system, thermal management components, and more sophisticated controls makes a hot press more complex. This translates directly to a higher initial investment and potentially higher maintenance costs over the machine's life.

Energy Consumption

The heating system is a significant source of energy use. For any operation, the energy required to bring the platens to temperature and maintain it during a cycle is a major operational cost that must be factored in.

Material Suitability

A hot press is a specialized tool. It is designed for materials that require thermal energy to be processed correctly. Using it for simple cold-forming operations is inefficient and not cost-effective.

Common Applications for Hot Hydraulic Presses

The unique combination of heat and pressure makes hot presses essential in several advanced manufacturing sectors.

Composite Manufacturing

Hot presses are used to mold Sheet Molded Composites (SMC), Glass Mat Transfer (GMT) plastics, and carbon fiber parts for the aerospace and automotive industries. The pressure consolidates the material layers while the heat cures the resin, creating strong, lightweight components.

Wood and Laminate Production

The manufacturing of plywood, particleboard, and decorative laminates relies on hot presses. Heat and pressure work together to activate the glue and bond the wood veneers or particles into a solid, stable sheet.

Thermoplastic and Rubber Molding

Hot presses are used to form parts from raw thermoplastics or rubber. The material is heated until it is pliable and then pressed into a mold, where it cools and hardens into the final desired shape.

Making the Right Choice for Your Application

Selecting the right press depends entirely on your material and your end goal.

- If your primary focus is forming or shaping metals at room temperature: A standard (cold) hydraulic press is the correct, more cost-effective tool for the job.

- If your primary focus is curing composites, bonding laminates, or molding plastics: A hot hydraulic press is essential, as the process itself relies on the combination of heat and pressure.

- If your primary focus is high-volume, automated production: Seek a hot press with advanced process controls and a robust hydraulic system to ensure consistent quality and cycle times.

Ultimately, understanding the fundamental interplay between heat and pressure is the key to leveraging this powerful technology for your specific manufacturing goal.

Summary Table:

| Feature | Hot Hydraulic Press | Standard (Cold) Hydraulic Press |

|---|---|---|

| Primary Function | Shapes materials using both heat and pressure | Shapes materials using pressure only |

| Key Components | Heated platens, hydraulic system, temperature controls | Hydraulic system only |

| Ideal For | Composites, plastics, wood laminates, rubber molding | Metal forming, stamping, assembly at room temperature |

| Process Outcome | Curing, bonding, thermal molding | Cold forming, bending, pressing |

Ready to enhance your manufacturing process with precise heat and pressure control?

KINTEK specializes in lab equipment and consumables, providing reliable hot hydraulic presses tailored to your laboratory and production needs. Whether you're curing advanced composites or bonding specialized materials, our solutions deliver consistent, repeatable results.

Contact us today to discuss how a KINTEK hot press can optimize your workflow and bring your material projects to life.

Visual Guide

Related Products

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating

- What is the function of a laboratory high-temperature hydraulic press? Optimize MEA Fabrication for HCl Electrolysis

- How much force can a hydraulic press exert? Understanding its immense power and design limits.

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing

- How does a heated laboratory hydraulic press facilitate densification in CSP? Optimize Mg-doped NASICON Sintering