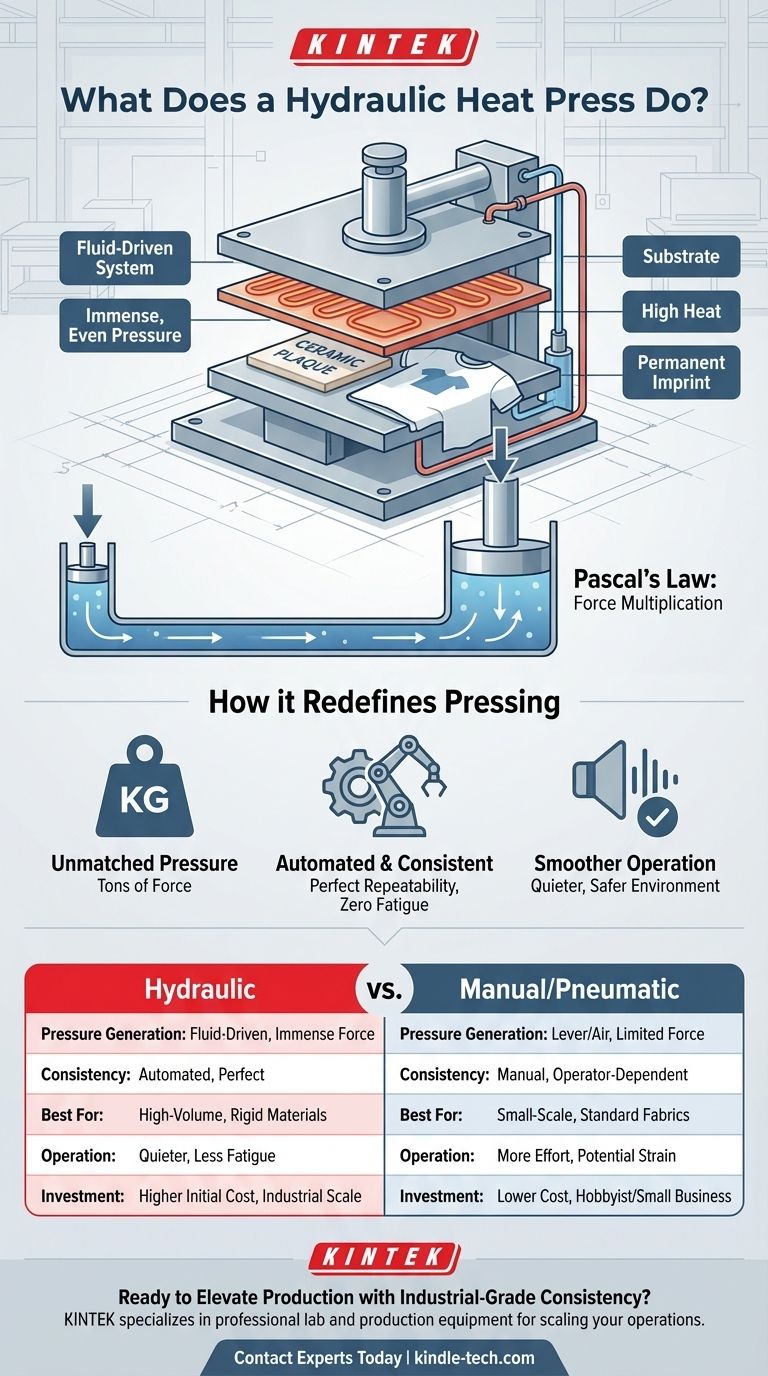

At its core, a hydraulic heat press is a commercial-grade machine that uses a fluid-driven system to apply immense, even pressure and high heat. This combination permanently imprints a design onto a substrate, such as apparel, ceramics, or plaques. Unlike manual presses that rely on human strength, a hydraulic press provides automated, perfectly repeatable pressure for a professional-quality finish every time.

A hydraulic heat press is not just about heat; it's about control and power. By using fluid dynamics (Pascal's Law) to generate force, it provides unparalleled pressure consistency, making it the definitive choice for high-volume production and demanding materials where other presses fall short.

How a Hydraulic System Redefines Pressing

A standard heat press has three variables: temperature, time, and pressure. While most presses control temperature and time electronically, the application of pressure is what separates the different types. The hydraulic model excels at mastering this third variable.

The Principle of Force Multiplication

A hydraulic press operates on Pascal's Law, a fundamental principle in fluid dynamics. This law states that pressure applied to a confined fluid is transmitted equally in all directions.

The press uses a small piston to apply a modest force to hydraulic fluid. This pressure is transmitted through the fluid to a much larger piston, which multiplies the initial force significantly. The result is the ability to generate immense compressive force with very little effort from the system's motor.

Automated and Consistent Operation

The key advantage is automation. The operator simply sets the desired pressure, and the hydraulic system engages, applies that exact force, and maintains it for the duration of the timer.

This removes the variables of operator fatigue or inconsistent force common with manual presses. Every single item receives the exact same pressure, ensuring product uniformity across a large production run.

Key Advantages Over Manual and Pneumatic Presses

Choosing a hydraulic press is a decision rooted in the need for industrial-scale power, consistency, and efficiency. It offers distinct benefits over simpler manual or air-powered pneumatic alternatives.

Unmatched Pressure for Demanding Jobs

Hydraulic systems can generate far more pressure, often measured in tons, than any manual or most pneumatic presses. This high tonnage is critical for ensuring proper adhesion on thick or challenging substrates like wood plaques, ceramic tiles, and other rigid materials.

Reduced Operator Fatigue

In a commercial setting, manually opening and closing a press hundreds of times a day leads to significant physical strain and potential inconsistencies. A hydraulic press automates this strenuous part of the process, allowing the operator to focus on loading and unloading garments, thereby increasing throughput and reducing labor costs.

Quieter, Smoother Operation

Compared to pneumatic (air-compressor-driven) presses, hydraulic systems are often significantly quieter and produce a smoother, less jarring motion. This can contribute to a better and safer working environment, especially in smaller workshops.

Understanding the Trade-offs

While powerful, a hydraulic press is not the right tool for every situation. Its industrial capabilities come with specific considerations.

Higher Initial Cost

The technology and engineering involved in a hydraulic system—including the pump, pistons, and reinforced frame—make these presses significantly more expensive upfront than manual models. This is a capital investment best suited for established, high-volume operations.

Size, Weight, and Maintenance

Hydraulic presses are heavy, robust machines that require dedicated floor space and cannot be easily moved. While built for longevity, they also require periodic maintenance of the hydraulic fluid and seals to prevent leaks and ensure optimal performance.

Overkill for Standard Applications

For a small business or hobbyist primarily printing on standard t-shirts and fabrics, the immense pressure of a hydraulic press is often unnecessary. A high-quality manual or auto-open clamshell press can deliver excellent results for these applications at a fraction of the cost.

Making the Right Choice for Your Operation

The decision to invest in a hydraulic heat press must be aligned with your specific production goals and the materials you work with.

- If your primary focus is high-volume commercial production: The automation, consistency, and reduction in operator fatigue make a hydraulic press an invaluable asset for maximizing output and ensuring quality control.

- If you work with thick, rigid, or unusual substrates: The immense and evenly distributed pressure of a hydraulic system is often required for a successful, permanent transfer on materials where manual presses fail.

- If you are a hobbyist or run a small-scale business: The cost and industrial scale of a hydraulic press are likely unnecessary; a high-quality manual press is a more practical and cost-effective solution.

Ultimately, understanding the hydraulic mechanism empowers you to select the right tool that aligns with your production scale, material needs, and long-term business goals.

Summary Table:

| Feature | Hydraulic Heat Press | Manual/Pneumatic Press |

|---|---|---|

| Pressure Generation | Fluid-driven (Pascal's Law), immense force (tons) | Lever/air pressure, limited force |

| Pressure Consistency | Automated, perfectly repeatable every time | Prone to operator fatigue and inconsistency |

| Best For | High-volume production, rigid materials (wood, ceramic) | Small-scale shops, standard fabrics (t-shirts) |

| Operation | Quieter, smoother, reduces operator fatigue | More manual effort, potential for strain |

| Investment | Higher initial cost, industrial-scale | Lower initial cost, hobbyist/small business scale |

Ready to elevate your production with industrial-grade consistency?

If your business demands high-volume output, works with challenging materials like wood or ceramic, and requires flawless, repeatable results, a hydraulic heat press is the definitive solution. KINTEK specializes in professional lab and production equipment, offering the robust machinery you need to scale your operations efficiently.

Contact our experts today to discuss how a hydraulic heat press can transform your workflow and boost your bottom line.

Visual Guide

Related Products

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Double Plate Heating Press Mold for Lab

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is a hot press used for? Bonding, Forming, and Transforming Materials with Precision

- What is the role of a temperature-controlled hydraulic press in Li6PS5Cl pellet preparation? Optimize Battery Density

- Why is a laboratory hot press essential for PTFE and nickel foam Zinc-Air electrodes? Precision Microstructure Control

- What is the standard temperature for heat press? Master the Perfect Settings for Durable Transfers

- What role does a heated hydraulic press play in Cold Sintering (CSP)? Enhancing LATP-Halide Densification

- What is hot press vs cold press machine? Choose the Right Method for Your Materials

- How does the presence of air in steam affect the hot pressing process? Eliminate Cold Spots and Maximize Efficiency

- What are the different types of press machines? Choose the Right Heating Tech for Your Application