To be clear, neither process is universally "better"—the optimal choice depends entirely on your specific application's requirements for durability, material, cost, and environmental impact. Generally, traditional chrome plating offers superior hardness and corrosion resistance for metal parts, while vacuum metalizing provides greater versatility for coating plastics and achieving a wider range of decorative finishes in a more environmentally friendly process.

The core decision comes down to a fundamental trade-off: Chrome plating provides maximum durability at a higher environmental cost, primarily for metals. Vacuum metalizing offers superior versatility and safety, making it ideal for decorative finishes on a wider range of materials, including plastics.

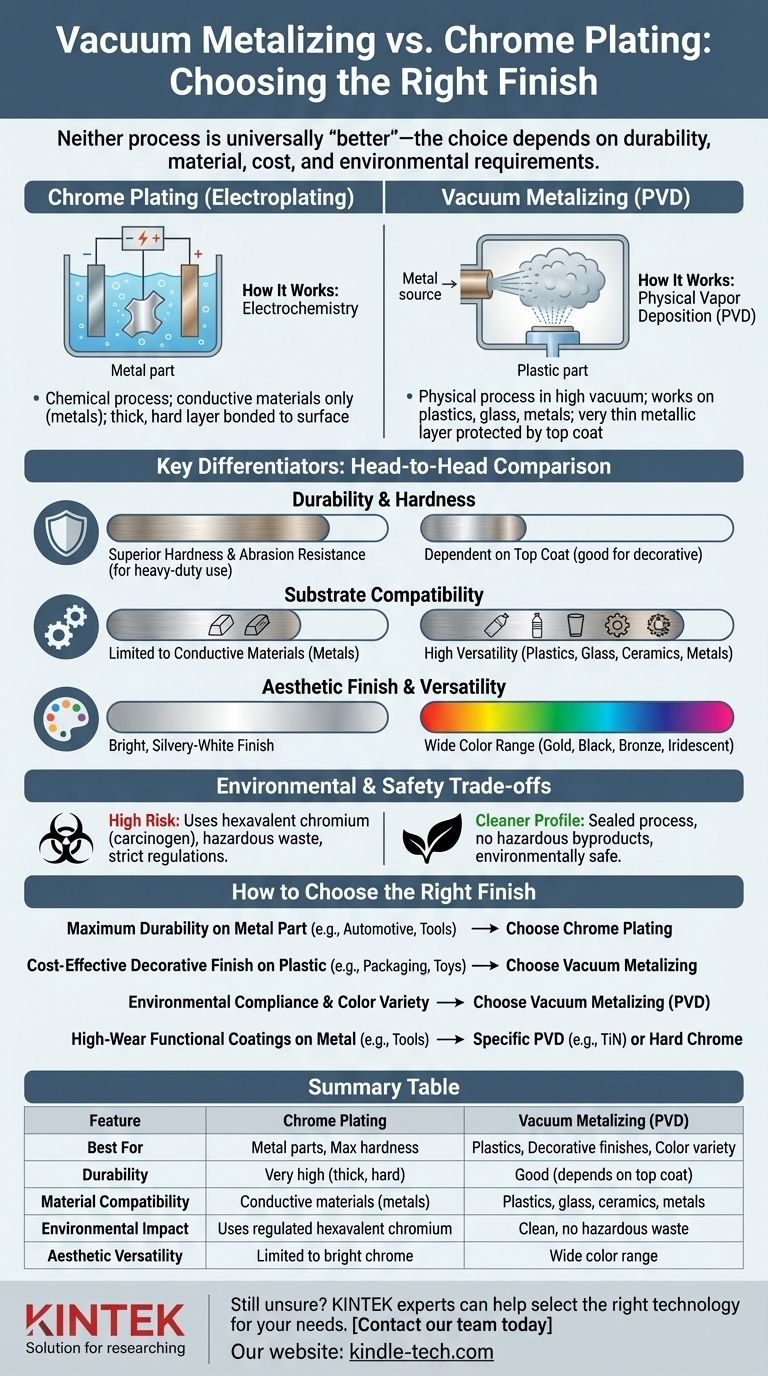

Understanding the Core Processes

To make an informed decision, you must first understand how fundamentally different these two technologies are. They achieve a similar look through completely different physical and chemical means.

How Chrome Plating Works: Electrochemistry in Action

Chrome plating is an electroplating process. The part, which must be conductive (typically a metal), is submerged in an electrolyte bath containing dissolved chromium.

An electric current is applied, causing the chromium ions in the solution to adhere to the part's surface, forming a strong, permanent metallic bond. This process builds a relatively thick, exceptionally hard outer layer.

How Vacuum Metalizing Works: Physical Vapor Deposition (PVD)

Vacuum metalizing, a form of Physical Vapor Deposition (PVD), is not a chemical process but a physical one. It occurs inside a high-vacuum chamber.

A solid metal, often aluminum, is vaporized into a cloud of atoms. The part to be coated is then passed through this cloud, and the metal vapor condenses onto its surface, forming a very thin, bright metallic layer. This layer is then almost always protected with a clear top coat for durability.

Key Differentiators: A Head-to-Head Comparison

Each process excels in different areas. Your choice will be dictated by which of these factors is most critical to your project's success.

Durability and Hardness

Chrome plating is the clear winner for heavy-duty applications. The electroplated layer is thick, hard, and directly bonded to the metal substrate, offering exceptional resistance to abrasion, impact, and wear.

Vacuum metalizing produces a much thinner coating. Its durability is almost entirely dependent on the hardness of the protective top coat applied over it. While suitable for decorative items, it will not withstand the harsh conditions that hard chrome plating is designed for.

Substrate Compatibility

This is a major point of difference. Chrome plating is effectively limited to conductive materials, meaning metals and alloys.

Vacuum metalizing is far more versatile. Because it's a physical deposition process, it works extremely well on plastics (like ABS, polycarbonate), glass, and ceramics in addition to metals. This makes it the default choice for adding a metallic finish to non-metal parts.

Aesthetic Finish and Versatility

While both can produce a brilliant, mirror-like "chrome" finish, vacuum metalizing offers a much broader aesthetic palette. By using different metals or alloys for deposition (like titanium or zirconium), PVD can create a wide spectrum of colors, including gold, black, bronze, and even iridescent rainbow finishes.

Chrome plating is largely limited to its signature bright, silvery-white appearance.

Understanding the Environmental and Safety Trade-offs

The operational and regulatory differences between these processes are significant and often drive the decision for modern manufacturing.

The Challenge of Hexavalent Chromium

Traditional chrome plating most often uses hexavalent chromium, a known carcinogen. The process creates hazardous waste and airborne emissions that are heavily regulated by environmental and health agencies worldwide (e.g., OSHA, EPA, REACH).

Managing these risks requires significant investment in safety equipment, ventilation, and waste treatment, which contributes to the higher cost of the process.

The Cleaner Profile of PVD

Vacuum metalizing (PVD) is, by comparison, an environmentally clean and safe process. It takes place in a sealed vacuum chamber and produces no hazardous byproducts, wastewater, or air pollutants.

This makes it a more sustainable and future-proof choice, free from the stringent regulatory burdens associated with hexavalent chromium.

How to Choose the Right Finish for Your Application

Selecting the correct process requires aligning its strengths with your product's primary goal.

- If your primary focus is maximum durability on a metal part: Choose chrome plating for its superior hardness and corrosion resistance, especially for automotive exteriors, industrial tools, or plumbing fixtures.

- If your primary focus is a cost-effective decorative finish on plastic: Choose vacuum metalizing for its unmatched ability to apply a brilliant metallic look to non-metal parts like cosmetic packaging, toys, or appliance logos.

- If your primary focus is environmental compliance and aesthetic choice: Choose vacuum metalizing (PVD) for its safe process and its ability to produce a wide range of colors beyond traditional chrome.

- If your primary focus is high-wear functional coatings on metal tools: A specific, high-performance type of PVD (like TiN coating) is often the modern choice, but for classic hardness, traditional hard chrome plating remains a benchmark.

Ultimately, your material and performance needs will make the choice clear.

Summary Table:

| Feature | Chrome Plating | Vacuum Metalizing (PVD) |

|---|---|---|

| Best For | Metal parts requiring maximum hardness | Plastics, decorative finishes, color variety |

| Durability | Very high (thick, hard layer) | Good (depends on top coat) |

| Material Compatibility | Conductive materials (metals) | Plastics, glass, ceramics, metals |

| Environmental Impact | Uses regulated hexavalent chromium | Clean, no hazardous waste |

| Aesthetic Versatility | Limited to bright chrome finish | Wide color range (gold, black, bronze, etc.) |

Still unsure which coating process is right for your materials and application?

At KINTEK, we specialize in lab equipment and consumables for surface treatment and coating analysis. Our experts can help you select the right technology for your specific needs, whether you're working with metals, plastics, or other substrates. We provide equipment and support for both traditional and advanced coating processes.

Contact our team today to discuss your project requirements and discover how we can help you achieve the perfect finish with optimal performance and efficiency.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Non Consumable Vacuum Arc Induction Melting Furnace

People Also Ask

- What is the purpose of sinter? Build Strong, Complex Parts from Powder

- What is the principle and working process of heat treatment? Unlock Desired Metal Properties

- What is vacuum heating? Achieve Purity and Precision in High-Temperature Processing

- What are the emissions of waste pyrolysis? A Guide to Cleaner Waste Transformation

- Why is a high-temperature pyrolysis furnace necessary for single-atom catalysts? Unlock Atomic Precision

- How do you braze a furnace? A Guide to High-Volume, Precision Metal Joining

- What is the process of arc melting? A Deep Dive into High-Temperature Metal Melting

- What are the advantages of sintering in powder metallurgy? Unlock Complex Parts with Minimal Waste