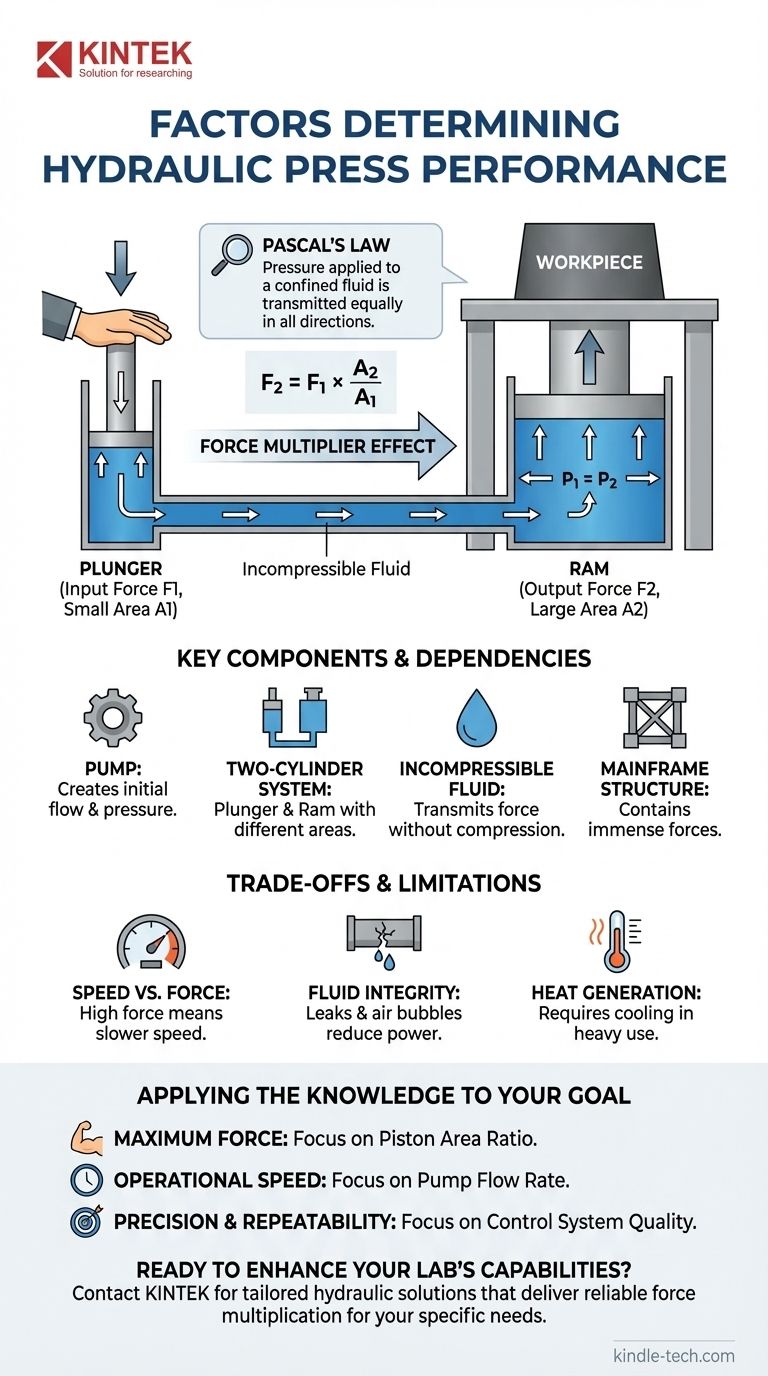

At its core, a hydraulic press depends on two primary factors: the amount of force applied to the hydraulic fluid and the surface areas of the two pistons it uses. The entire principle of its operation hinges on Pascal's Law, which dictates how pressure is transmitted through a confined, incompressible fluid to multiply force dramatically.

The fundamental concept to grasp is that a hydraulic press does not create energy, but rather multiplies force. It achieves this by applying a small force over a small area, transmitting the resulting pressure through a fluid to a large area, which generates a proportionally larger output force.

The Fundamental Principle: Pascal's Law

The operation of every hydraulic press is a direct application of a core principle of fluid mechanics known as Pascal's Law. Understanding this law is key to understanding the machine.

What is Pascal's Law?

Pascal's Law states that when pressure is applied to a fluid in a confined space, that pressure is transmitted equally and undiminished in all directions throughout the fluid.

Imagine squeezing a water balloon. The pressure you apply with your fingers is felt uniformly across the entire inner surface of the balloon, not just where you are squeezing. A hydraulic press uses this principle in a controlled system.

The Force Multiplier Effect

The formula for pressure is Pressure (P) = Force (F) / Area (A).

In a hydraulic system with a small piston (Plunger) and a large piston (Ram), the pressure exerted on both is the same (P1 = P2). This leads to the central equation: F1/A1 = F2/A2.

This means a small force applied to the small piston generates a much larger force on the big piston, directly proportional to the difference in their areas. This is the "magic" of the hydraulic press.

The Core Mechanical Components

While the principle is simple, its execution depends on several critical, interconnected components working together flawlessly.

The Two-Cylinder System

Every hydraulic press is built around two cylinders of different sizes, each with its own piston.

The smaller cylinder, often called the Plunger, is where the initial, smaller force is applied. The larger cylinder, called the Ram, is where the multiplied, larger force is delivered to do the work.

The Incompressible Fluid

The system depends on a fluid that resists compression under pressure, which is typically a specialized hydraulic oil.

This property is critical. If the fluid could be easily compressed, the initial force would be wasted on squeezing the fluid itself rather than being transmitted to the larger piston.

The Power System (Pump)

A pump is the component responsible for creating the initial flow and pressure in the hydraulic fluid. This pump does the work of applying the initial force to the small piston, starting the entire process.

The Mainframe Structure

The immense forces generated by the press must be contained. The mainframe is the robust, rigid structure that holds the cylinders and the workpiece, ensuring the force is directed effectively without breaking the machine apart.

Understanding the Trade-offs

The force multiplication of a hydraulic press is not without its compromises. Understanding these limitations is crucial for its proper application.

The Speed vs. Force Compromise

There is an unavoidable trade-off between force and distance. To move the large Ram a short distance, the small Plunger must be moved a much greater distance.

This is why hydraulic presses are incredibly powerful but often operate at a relatively slow speed.

Fluid Integrity is Critical

The system's performance is entirely dependent on the condition of the hydraulic fluid.

Any leaks will cause a loss of pressure and power. Air bubbles in the fluid are compressible and will severely dampen the force transfer. Contamination can damage seals and components, leading to failure.

Heat Generation

Moving fluid under high pressure generates heat. In continuous, heavy-duty applications, this heat can degrade the oil and damage seals. Many industrial presses depend on cooling systems to maintain stable operating temperatures.

How to Apply This to Your Goal

Understanding these dependencies allows you to determine the right press configuration for a specific task.

- If your primary focus is maximum force: The most critical factor is the size ratio between the Ram (large piston) and the Plunger (small piston). A larger ratio yields greater force multiplication.

- If your primary focus is operational speed: The key factor becomes the pump's flow rate (gallons or liters per minute). A higher flow rate enables the cylinders to move faster, though often at the expense of maximum pressure.

- If your primary focus is precision and repeatability: The quality and sophistication of the hydraulic control system and electronic components become the most important dependencies for your success.

Ultimately, a hydraulic press is a system where a scientific principle and mechanical design are perfectly intertwined to achieve extraordinary results.

Summary Table:

| Key Factor | Impact on Performance |

|---|---|

| Piston Area Ratio | Determines the force multiplication capability (F2 = F1 × (A2/A1)) |

| Hydraulic Fluid Quality | Affects pressure transmission efficiency and system reliability |

| Pump Type & Flow Rate | Controls operational speed and pressure generation |

| Mainframe Strength | Ensures structural integrity under high force conditions |

| Control System | Provides precision, repeatability, and safety during operation |

Need a hydraulic press tailored to your specific force, speed, and precision requirements?

At KINTEK, we specialize in designing and supplying high-performance lab equipment, including hydraulic presses that deliver reliable force multiplication for your most demanding applications. Our experts can help you select the perfect configuration based on your specific needs—whether you require maximum force, faster cycle times, or precise control.

Contact us today to discuss how KINTEK's hydraulic solutions can enhance your laboratory's capabilities and efficiency!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Manual Lab Heat Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy