At its core, a pyrolysis apparatus is a system designed for thermal decomposition in an oxygen-free environment. The essential components include a pyrolysis reactor to contain the material, an electric heating system, a raw material feeder to introduce the feedstock, and separate systems to collect the resulting solid (biochar), liquid (bio-oil), and gaseous (syngas) products.

The fundamental purpose of any pyrolysis apparatus is to create a precisely controlled, high-temperature, oxygen-starved environment. While components vary by scale, every system must effectively contain the feedstock, apply heat, and safely manage the resulting outputs.

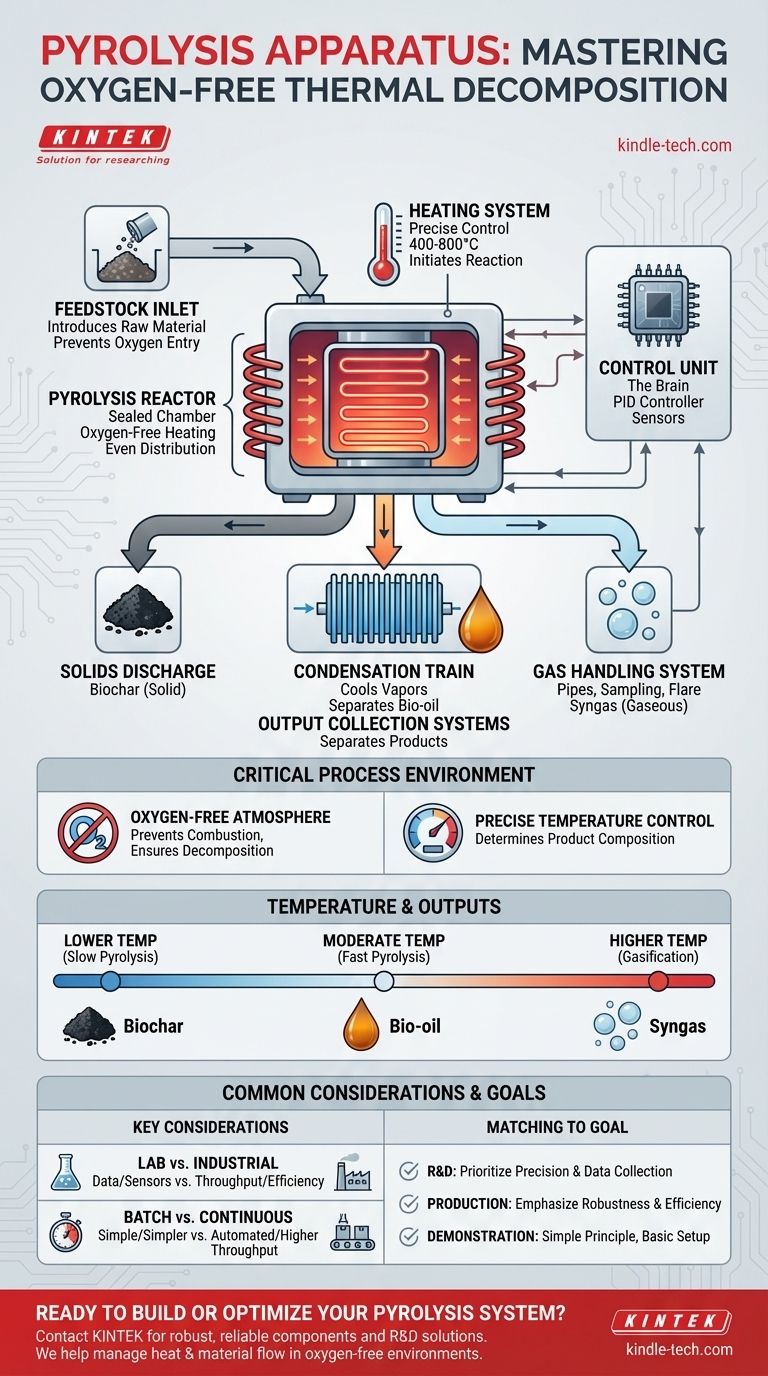

The Core Components of a Pyrolysis System

Understanding the function of each component reveals how the entire process works. The system is more than just a furnace; it's a controlled chemical reactor.

The Pyrolysis Reactor: The Heart of the Operation

This is the central, sealed chamber where the raw material is heated without oxygen. Its design is critical for ensuring even heat distribution and for preventing air from leaking in, which would cause combustion instead of pyrolysis.

The Heating System: Initiating the Reaction

An external heating system, often electric for precise control, surrounds the reactor. It must be capable of reaching and maintaining specific temperatures (often 400-800°C) to break down the feedstock into the desired products.

The Feedstock Inlet: Introducing the Raw Material

This mechanism, which can range from a simple manual port in a lab setup to an automated auger in a continuous system, is used to load raw material into the reactor. A key design challenge is feeding material without introducing oxygen.

The Output Collection Systems: Separating the Products

Once the reaction occurs, the mixed-phase products must be separated. This typically involves multiple stages:

- A solids discharge to remove the biochar from the reactor.

- A condensation train to cool the hot vapors, causing the bio-oil to liquefy and separate from the non-condensable syngas.

- A gas handling system, which may include pipes, a sampling interface for analysis, or a burning device (flare) to safely dispose of or utilize the syngas.

The Control Unit: The Brains of the System

A control cabinet, often managed by a PID (Proportional-Integral-Derivative) controller, acts as the system's brain. It uses sensors to monitor temperature and gas flow, precisely adjusting the heating element to maintain the target conditions for the reaction.

Understanding the Critical Process Environment

The components are designed to serve two non-negotiable process requirements: the absence of oxygen and the precise application of heat.

The Necessity of an Oxygen-Free Atmosphere

Pyrolysis is, by definition, thermal decomposition without oxidation. If oxygen is present in the reactor, the feedstock will simply burn (combust). The entire apparatus—from the sealed reactor to the feedstock inlet—is designed to maintain an inert or near-inert atmosphere.

The Role of Precise Temperature Control

Temperature is the primary lever for controlling the output of the pyrolysis process. A sophisticated temperature control system allows the operator to target specific products:

- Lower temperatures (slow pyrolysis) favor the production of solid biochar.

- Moderate temperatures (fast pyrolysis) favor the production of liquid bio-oil.

- Higher temperatures (gasification) favor the production of gaseous syngas.

Common Pitfalls and Considerations

The design and operation of a pyrolysis apparatus are subject to significant trade-offs based on its intended application.

Lab Scale vs. Industrial Scale

The apparatus described in laboratory settings is optimized for data collection, using sensitive sensors and gas sampling ports. Industrial-scale systems prioritize throughput, robustness, and energy efficiency, requiring far more complex material handling and heat integration systems.

Batch vs. Continuous Processing

A batch process involves loading the reactor, running the cycle, cooling it down, and then removing the products. It is simpler but less efficient. A continuous process, which uses automated feeders and discharge systems, offers higher throughput but presents greater mechanical complexity.

Feedstock Consistency

The apparatus must be designed for the specific type of raw material being processed. The size, moisture content, and density of the feedstock dramatically affect how it flows through the feeder, how it heats within the reactor, and the composition of the final products.

Matching the Apparatus to Your Goal

The right design depends entirely on your objective.

- If your primary focus is research and development: Prioritize an apparatus with precise PID temperature control, multiple sensors, and a gas sampling interface for detailed data collection.

- If your primary focus is industrial production: Emphasize a robust, continuous feeding system, efficient heat recovery, and automated output collection systems to maximize throughput and minimize operating costs.

- If your primary focus is basic demonstration: A simple, sealed retort with an external heat source can show the principle, but lacks the control and safety features necessary for repeatable or safe operation.

Ultimately, every component of a pyrolysis apparatus serves the singular goal of controlling heat and managing material flow in an oxygen-free world.

Summary Table:

| Component | Primary Function | Key Consideration |

|---|---|---|

| Pyrolysis Reactor | Sealed chamber for oxygen-free heating | Design ensures even heat distribution and prevents air leaks |

| Heating System | Provides precise high-temperature heat (400-800°C) | Often electric for control; initiates the decomposition reaction |

| Feedstock Inlet | Introduces raw material into the reactor | Must feed material without introducing oxygen |

| Output Collection | Separates and collects biochar, bio-oil, and syngas | Involves solids discharge, condensation train, and gas handling |

| Control Unit | Monitors and adjusts temperature and process conditions | Uses PID controllers and sensors for precise control |

Ready to build or optimize your pyrolysis system? Whether you are scaling up for industrial production or require precise control for R&D, KINTEK's expertise in lab equipment and consumables is your solution. We provide the robust, reliable components and systems needed to efficiently manage heat and material flow in an oxygen-free environment. Contact our experts today to discuss how we can support your laboratory's specific pyrolysis needs and help you achieve your project goals.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What are the benefits of a tube furnace? Achieve Superior Temperature & Atmosphere Control

- How do you clean a tube furnace tube? A Step-by-Step Guide to Safe and Effective Cleaning

- Why is an Alumina Ceramic Tube Support Necessary for 1100°C Experiments? Ensure Data Accuracy and Chemical Inertness

- What are the advantages of using an alumina liner in a tube furnace for biomass combustion corrosion simulations?

- What tube is used for tubular furnace? Choose the Right Material for Temperature & Atmosphere