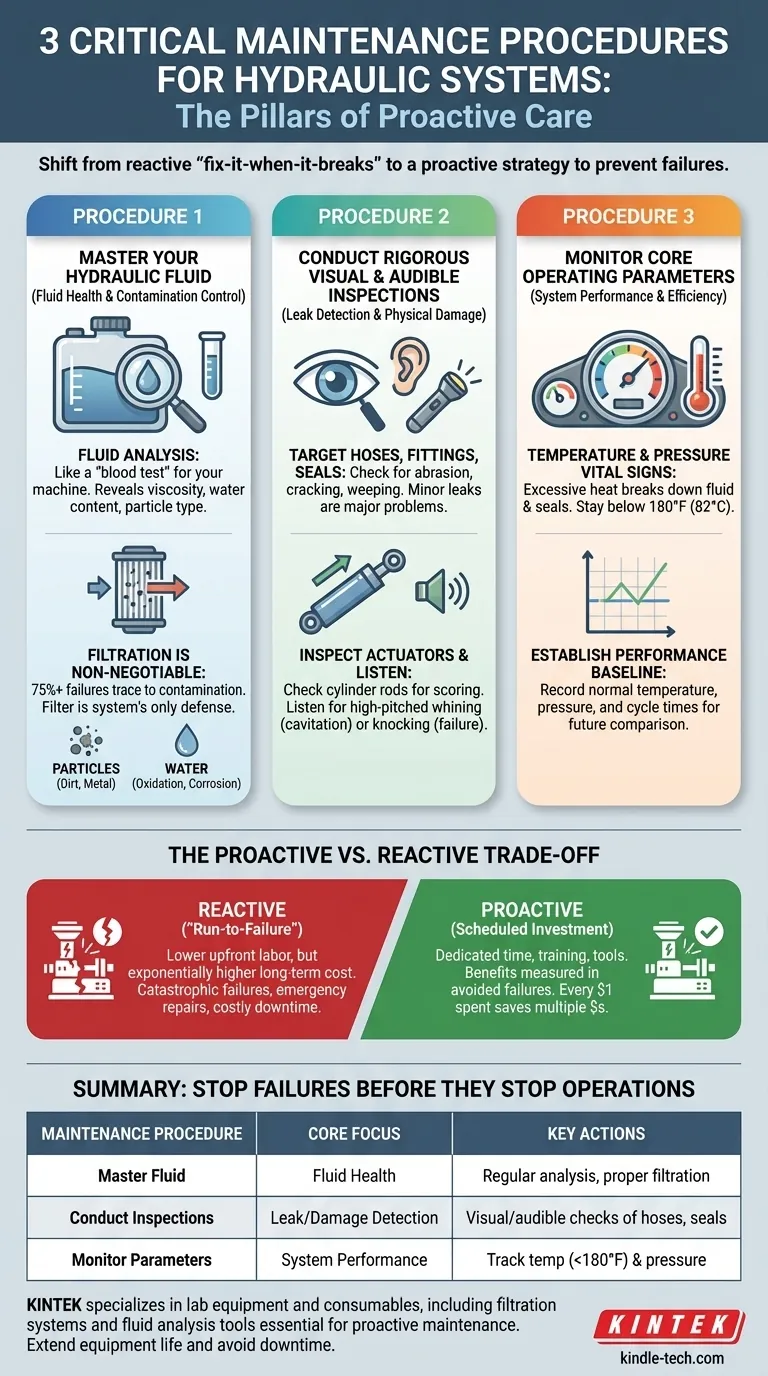

The three most critical maintenance procedures for any hydraulic system are managing fluid cleanliness, inspecting for leaks and physical damage, and monitoring operating temperature and pressure. These three pillars of proactive care are not just routine tasks; they are the primary defense against the contamination, degradation, and operational stress that cause over 90% of all system failures.

Hydraulic system failures are rarely sudden events. They are the result of progressive, often invisible, issues. The core principle of effective maintenance is to shift from a reactive "fix-it-when-it-breaks" model to a proactive strategy focused on preserving fluid health and identifying warning signs before they become catastrophic.

Procedure 1: Master Your Hydraulic Fluid

The fluid is the single most important component in a hydraulic system. It acts as a power transmission medium, a lubricant, and a heat transfer agent. Its health dictates the health of the entire system.

Why Fluid Analysis is Essential

Think of fluid analysis as a blood test for your machine. Sending a small sample to a lab provides critical data on viscosity, water content, and the type and quantity of particle contamination.

This analysis tells you not just if there's a problem, but what the problem is. For example, high levels of brass particles might indicate a pump is beginning to fail, allowing you to schedule a replacement before it implodes and contaminates the entire system.

Contamination: The Silent Killer

More than 75% of hydraulic failures are traced back to fluid contamination. There are two primary culprits: particles (dirt, metal flakes) and water.

Particles cause abrasive wear, silting up valves and scoring cylinders. Water promotes oxidation, reduces lubricity, and causes corrosion. Both drastically shorten the life of every component in the system.

Filtration is Non-Negotiable

Filters are your system's only defense against contamination. Simply having a filter is not enough; it must be the correct type and it must be changed based on a schedule or condition indicator.

A clogged filter will go into bypass mode, allowing dirty, unfiltered fluid to circulate freely, accelerating wear on the most expensive components like pumps and motors.

Procedure 2: Conduct Rigorous Visual & Audible Inspections

You can diagnose many developing issues with your own eyes and ears long before they cause a shutdown. A routine, systematic inspection is a simple but powerful tool.

Target Hoses, Fittings, and Seals

These are the most common points of failure. Look for any signs of abrasion, cracking, blistering, or weeping on hoses. Check all fittings to ensure they are secure and not leaking.

Even a minor leak is a major problem. It’s an escape point for expensive fluid and, more importantly, an entry point for dirt, air, and moisture.

Inspect Actuators and Reservoirs

Check cylinder rods for any scoring, pitting, or corrosion. A damaged rod will destroy its seals, leading to leaks.

Periodically inspect the inside of the reservoir. The presence of sludge, sediment, or a milky fluid appearance (indicating water) are clear signs of a serious contamination problem that must be addressed immediately.

Listen for Abnormal Sounds

A healthy hydraulic system has a consistent, smooth sound. Listen for changes. A high-pitched whining sound often indicates pump cavitation (air in the system), while knocking or grinding can signal a failing pump or motor.

Procedure 3: Monitor Core Operating Parameters

Temperature and pressure are the vital signs of your hydraulic system. Consistent monitoring and logging of these parameters provide the earliest warning of internal inefficiencies or developing failures.

Why Temperature is a Critical Vital Sign

Excessive heat is a primary enemy of hydraulic systems. It breaks down the fluid, destroying its viscosity and lubricating properties. It also degrades seals, making them hard and brittle.

Most standard systems are designed to operate below 180°F (82°C). Consistently high temperatures indicate a problem with the system's ability to dissipate heat, such as a dirty cooler, low reservoir fluid level, or internal component inefficiency.

The Importance of System Pressure

Use gauges to monitor the system's operating pressure during a normal cycle. A pressure reading that is too low, too high, or fluctuates erratically indicates a problem.

This could be a poorly set relief valve, an inefficient pump, or an internal leak that is robbing the system of power.

Establish a Performance Baseline

You cannot identify an abnormal condition if you don't know what is normal. When a system is healthy, record its baseline temperatures, pressures, and cycle times. This data becomes the benchmark against which all future inspections are compared.

Understanding the Key Trade-off: Proactive vs. Reactive

Choosing your maintenance strategy is a conscious decision with significant financial consequences.

The High Cost of "Run-to-Failure"

A reactive, "run-to-failure" approach may seem cheaper in the short term because it involves less upfront labor. However, it is exponentially more expensive over the life of the equipment.

This strategy leads to catastrophic failures that cause extensive secondary damage, require emergency repairs at premium rates, and result in costly, unplanned downtime.

The Investment of Proactive Maintenance

Proactive maintenance requires a dedicated investment in time, training, and tools. It involves scheduled tasks, fluid analysis costs, and keeping spare parts like filters and seals in inventory.

This approach requires discipline and management buy-in, as its benefits are measured in the failures that don't happen.

The Clear Return on Investment

The data is clear: every dollar spent on proactive maintenance saves multiple dollars in avoided repair costs and lost production. It extends the life of capital equipment, improves safety, and makes operational budgets far more predictable.

Building a Practical Maintenance Schedule

How you apply these principles depends on your operational goals and the criticality of the equipment.

- If your primary focus is maximum reliability for critical systems: Implement a strict schedule of quarterly fluid analysis and component inspections, logging all data to track performance trends over time.

- If your primary focus is managing a large fleet of equipment: Empower operators to be the first line of defense by training them to perform consistent daily checks for leaks, fluid levels, and abnormal temperatures or sounds.

- If your primary focus is reducing maintenance costs: Prioritize fluid cleanliness by enforcing a strict filter-change schedule, as this single area prevents the most expensive and widespread component failures.

An effective maintenance program transforms your hydraulic systems from a potential liability into a consistently reliable asset.

Summary Table:

| Maintenance Procedure | Core Focus | Key Actions |

|---|---|---|

| Master Your Hydraulic Fluid | Fluid Health & Contamination Control | Regular fluid analysis, proper filtration, monitor for water/particles |

| Conduct Rigorous Inspections | Leak Detection & Physical Damage | Visual/audible checks of hoses, seals, cylinders; listen for abnormal sounds |

| Monitor Operating Parameters | System Performance & Efficiency | Track temperature (<180°F/82°C) and pressure; establish performance baselines |

Stop hydraulic failures before they stop your operations.

KINTEK specializes in providing reliable lab equipment and consumables, including filtration systems and fluid analysis tools essential for proactive hydraulic maintenance. Our solutions help you implement these critical procedures, extend equipment life, and avoid costly downtime.

Ready to build a more reliable maintenance program? Contact our experts today to discuss your specific laboratory equipment needs and how we can support your operational goals.

Visual Guide

Related Products

- Manual Lab Heat Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

People Also Ask

- What is the history of the hydraulic press? From Pascal's Principle to Industrial Revolution Powerhouse

- What is die compression ratio? Master Your Pelleting Process for Optimal Quality & Efficiency

- What is the ratio of KBr to drug substance for FTIR analysis? Achieve Perfect Sample Preparation for Clear Spectra

- What is pressed pellets? Transform Powders into Reliable Solid Samples for Analysis

- Importance of Precision Hydraulic Pressing in TRISO Fuel Pellet Fabrication: Ensure Integrity and Performance

- What is the difference between injection molding and pressure molding? A Guide to Choosing the Right Process

- What are the failures of a hydraulic press? Prevent Downtime and Ensure Safety in Your Lab

- What is the purpose of using a laboratory hydraulic press for pre-pressure? Enhance Sintering Precision & Density