Sintering is a manufacturing process that uses heat and pressure to form a solid mass of material from a powder without melting it to the point of liquefaction. Its primary advantages are the ability to create strong, complex parts from materials with very high melting points, enhance material properties like strength and conductivity, and achieve near-net shapes with minimal waste.

Sintering provides a powerful and cost-effective method for creating high-performance components, especially from difficult-to-work-with materials. However, its success hinges on precise control over process variables to manage the inherent trade-offs between final density, dimensional accuracy, and porosity.

The Core Advantages of Sintering

Sintering is not just an alternative to melting and casting; it offers unique benefits that make it the superior or only choice for many advanced applications.

Handling High-Melting-Point Materials

The process occurs at temperatures below the material's melting point.

This is sintering's most significant advantage. It allows for the fabrication of parts from materials like tungsten, molybdenum, and advanced ceramics, which have melting points so high that melting and casting them would be impractical or prohibitively expensive.

Creating Complex, Near-Net Shapes

Sintering excels at producing intricate geometries directly from the powder compact.

This "near-net shape" capability drastically reduces or eliminates the need for secondary machining operations. By minimizing material waste and post-processing, sintering is a highly cost-effective and environmentally friendly process, especially for high-volume production.

Enhancing Material Properties

Sintering fundamentally transforms a loose powder into a dense, coherent object, improving its physical characteristics.

During the process, diffusion bonding occurs at the contact points between particles. This reduces porosity, increases density, and enhances properties such as mechanical strength, thermal conductivity, and electrical conductivity. For some ceramics, it can even increase translucency.

Achieving High Purity and Repeatability

The process begins with highly controlled starting powders, ensuring uniformity and purity from the outset.

Because key parameters like temperature, pressure, and atmosphere are precisely managed, sintering is a highly repeatable operation. This leads to consistent results and fewer imperfections compared to traditional melting, where segregation and inclusions can be a problem.

Understanding the Trade-offs and Limitations

While powerful, sintering is not without its challenges. Understanding its inherent limitations is critical for successful application.

The Challenge of Residual Porosity

While sintering significantly reduces the empty space between particles, it can be difficult to eliminate it completely.

This residual porosity can impact the final mechanical properties of the part, potentially making it less strong than a fully dense equivalent produced by melting. While this porosity can be controlled and is sometimes even desirable (e.g., for filters), it is a critical factor to manage.

Shrinkage and Dimensional Control

As the powder compact densifies and porosity is reduced, the entire part shrinks.

This shrinkage is a natural part of the process but must be precisely predicted and controlled to achieve tight dimensional tolerances. This often requires significant empirical testing or sophisticated theoretical modeling to get right.

Limitations on Part Size

The initial "green body" is typically formed by compacting powder in a die.

The pressure required for compaction and the practicalities of furnace size can place limits on the maximum size of components that can be produced. Very large parts are often difficult to sinter effectively using common methods.

Process Complexity

Achieving optimal results requires a deep understanding of the material and process variables.

The influence of powder grain size, heating rates, sintering temperature, and atmospheric conditions must all be carefully balanced. Furthermore, the initial stage often involves burning off residual binders, which adds another critical step to the process.

Making the Right Choice for Your Goal

Selecting sintering requires matching its unique capabilities to your specific engineering and economic requirements.

- If your primary focus is manufacturing with high-melting-point materials: Sintering is an unparalleled and energy-efficient solution for materials like ceramics, carbides, and refractory metals.

- If your primary focus is cost-effective, high-volume production of complex parts: Sintering's near-net shape capability makes it an excellent choice for reducing material waste and post-processing costs.

- If your primary focus is achieving absolute maximum density for critical applications: Standard sintering may not be sufficient, and you should consider advanced techniques like hot isostatic pressing (HIP) or alternative manufacturing methods.

By understanding both its powerful advantages and inherent limitations, you can effectively leverage sintering to create high-performance parts that would be difficult or impossible to produce otherwise.

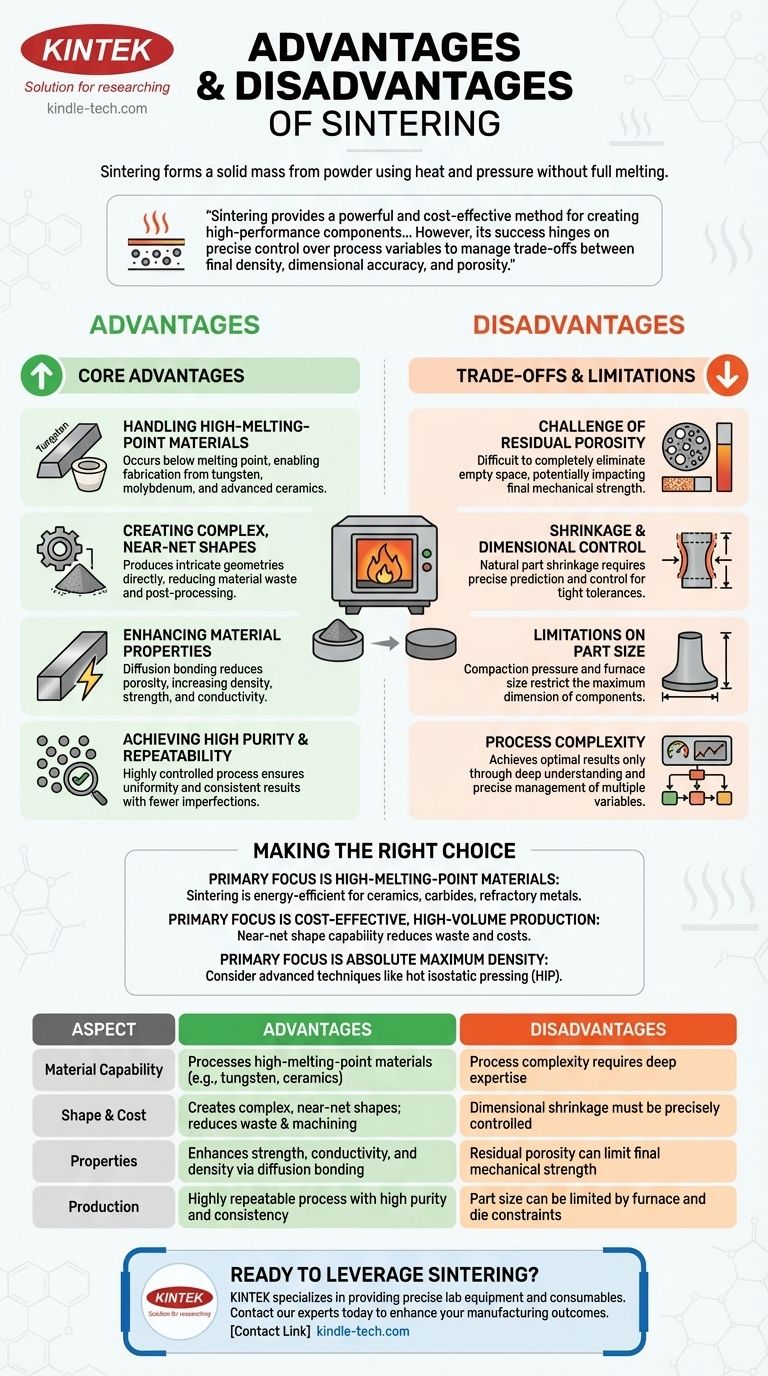

Summary Table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Material Capability | Can process high-melting-point materials (e.g., tungsten, ceramics) | Process complexity requires deep expertise |

| Shape & Cost | Creates complex, near-net shapes; reduces waste and machining | Dimensional shrinkage must be precisely controlled |

| Properties | Enhances strength, conductivity, and density via diffusion bonding | Residual porosity can limit final mechanical strength |

| Production | Highly repeatable process with high purity and consistency | Part size can be limited by furnace and die constraints |

Ready to leverage sintering for your high-performance components? KINTEK specializes in providing the precise lab equipment and consumables needed to master the sintering process. Whether you're working with advanced ceramics, refractory metals, or complex geometries, our solutions help you achieve optimal density, dimensional accuracy, and material properties. Contact our experts today to discuss how we can support your laboratory's sintering challenges and enhance your manufacturing outcomes.

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the heating range of a muffle furnace? From 800°C to 1800°C for Your Lab Needs

- What are the features of muffle furnace? Unlock Clean, Precise High-Temperature Processing

- What are the advantages of a muffle furnace? Achieve Purity and Precision in High-Temp Processing

- What is the safety of a muffle furnace? Ensuring Secure Operation with Modern Design and Protocols

- What is the temperature setting of a muffle furnace? Select the Right Model for Your Process