The primary advantages of induction heating are its exceptional speed, precision, and cleanliness. By using an electromagnetic field to generate heat directly inside a conductive material, it eliminates the need for direct contact with a flame or heating element, resulting in a faster, more efficient, and highly controllable process.

The core value of induction heating lies in its ability to heat a part from the inside out. This fundamental difference from conventional methods—which heat from the outside in—is the source of its most significant benefits, including superior speed, energy efficiency, and process control.

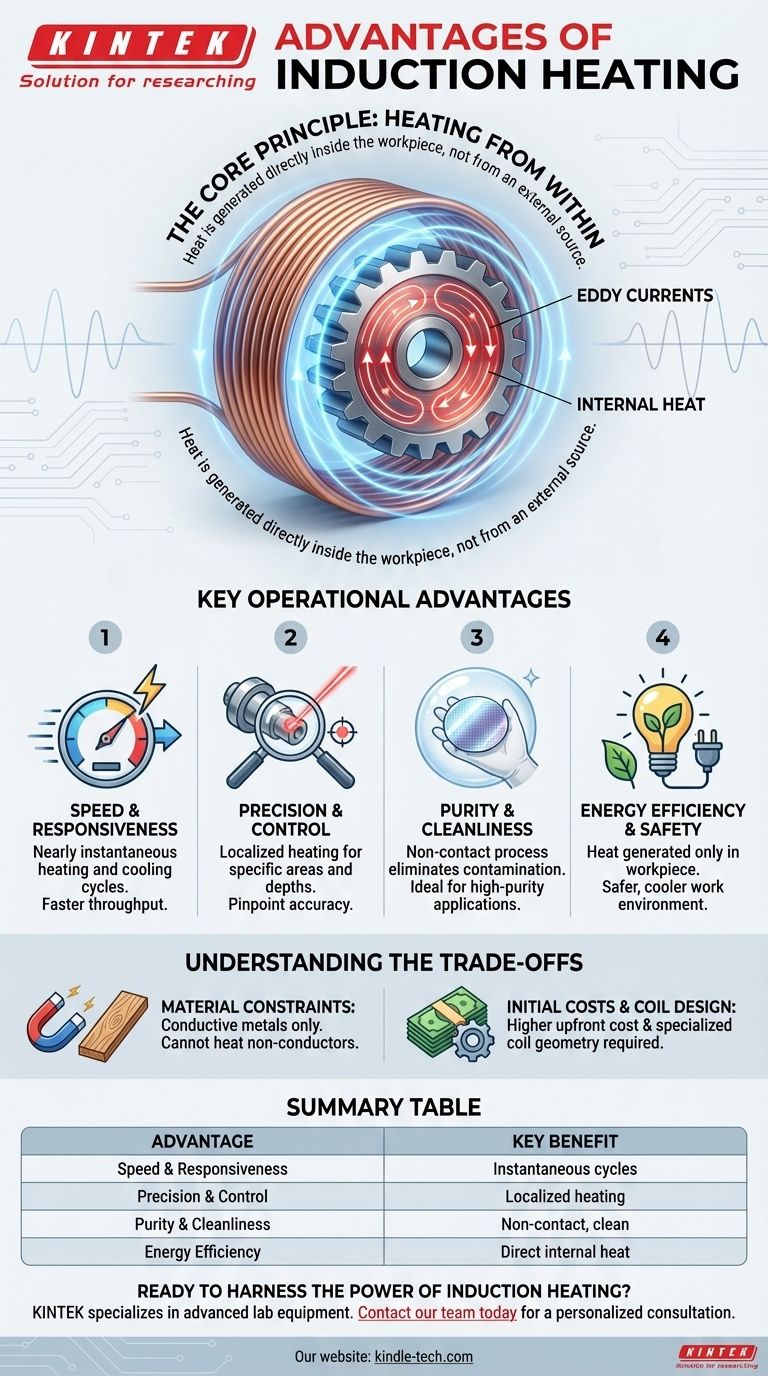

The Core Principle: Heating from Within

Induction heating is not a new technology, but its principles are fundamentally different from traditional furnaces. Understanding this distinction is key to appreciating its advantages.

How It Works: The Role of Electromagnetism

An induction system passes a high-frequency alternating current through a specifically designed copper coil. This creates a powerful, rapidly changing magnetic field around the coil.

When an electrically conductive part (the workpiece) is placed within this field, the magnetic field induces electrical currents, known as eddy currents, inside the part itself. The natural resistance of the material to the flow of these currents generates precise and instantaneous heat.

The Impact of Internal Heat Generation

Because the heat is generated within the workpiece, the process does not rely on slower thermal conduction from an external source. This internal generation is the source of its most powerful benefits.

Key Operational Advantages

This unique heating mechanism translates directly into tangible benefits for industrial processes, from metallurgy to semiconductor manufacturing.

Unmatched Speed and Responsiveness

Heating is nearly instantaneous and can be stopped immediately. This allows for extremely rapid heating cycles, increasing throughput and allowing for agile production changes without long furnace warm-up or cool-down times.

Pinpoint Precision and Control

The magnetic field can be precisely focused. This allows you to heat a very specific, localized area of a part to a controlled depth, a process known as induction hardening. You can strengthen a wear surface on a gear tooth, for example, while leaving the core of the gear ductile and tough.

Superior Purity and Cleanliness

Induction is a non-contact process. The part is never touched by a flame or a physical heating element. This completely eliminates contamination from combustion byproducts or contact materials, making it ideal for high-purity applications in the medical and semiconductor industries.

Enhanced Energy Efficiency and Safety

Heat is generated only in the workpiece, not in the surrounding atmosphere or furnace walls. This makes induction highly energy-efficient, as minimal energy is wasted. This also contributes to a safer, cooler work environment compared to the ambient heat produced by large furnaces.

Understanding the Trade-offs and Considerations

While powerful, induction heating is not a universal solution. Its effectiveness is dependent on specific conditions, and it comes with unique requirements.

Material Constraints: Conductors Only

The process fundamentally relies on inducing electrical currents. Therefore, it is only effective on electrically conductive materials, primarily metals. It cannot be used to directly heat non-conductors like ceramics, polymers, or glass.

Initial Equipment and Coil Design Costs

Induction systems, which include a solid-state power supply and custom inductors, can have a higher upfront capital cost than a simple convection oven or gas furnace. The efficiency of the system is also highly dependent on the design of the coil.

The Critical Role of Coil Geometry

The inductor (coil) must be carefully designed for the specific part and heating pattern required. The distance between the coil and the workpiece, and the shape of the coil itself, dramatically impact the efficiency and uniformity of the heating. This often requires specialized expertise.

Making the Right Choice for Your Application

The decision to use induction heating should be driven by your process goals.

- If your primary focus is high-volume, repeatable manufacturing: Induction's speed and precise digital control deliver unmatched consistency and throughput.

- If your primary focus is component purity: The non-contact nature of induction heating provides the cleanest possible environment, eliminating all sources of combustion or contact contamination.

- If your primary focus is localized heat treatment: Induction is the superior choice for hardening specific surfaces or sections of a part without altering the properties of the entire component.

Ultimately, induction heating provides a level of control over the heating process that traditional methods simply cannot match.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Speed & Responsiveness | Nearly instantaneous heating and cooling cycles |

| Precision & Control | Localized heating for specific areas and depths |

| Purity & Cleanliness | Non-contact process eliminates contamination |

| Energy Efficiency | Heat is generated directly within the workpiece |

Ready to harness the power of induction heating in your lab or production line?

KINTEK specializes in advanced lab equipment and consumables, providing induction heating solutions that deliver the speed, precision, and purity your processes demand. Our experts can help you select the right system to boost your throughput, ensure product quality, and improve safety.

Contact our team today for a personalized consultation and discover how KINTEK can optimize your thermal processing.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Double Plate Heating Press Mold for Lab

People Also Ask

- What is the purpose of introducing hydrogen or argon gas into a vacuum hot pressing furnace during sintering or cooling?

- How does using a Vacuum Hot Pressing Machine improve Copper-MoS2-Mo? Achieve Superior Material Density & Performance

- How temperature control precision affects Ti/Al composites? Master Vacuum Hot Pressing for Superior Material Plasticity

- How does the vacuum environment within a hot-pressing furnace improve the performance of B4C/Al composites? Boost Density

- How does the degassing stage in a vacuum hot press (VHP) optimize diamond/aluminum composite performance?