In materials science and engineering, a deposition product is the solid material, typically a thin film or coating, that is intentionally formed on a surface (known as a substrate). This is achieved through a controlled process where a material is transitioned from a gas, liquid, or plasma phase into a solid layer. The "product" is this newly formed layer, whose properties are precisely engineered for a specific function.

The term "deposition product" refers less to a specific substance and more to the result of a highly controlled engineering process. The value and function of the product are defined not just by what material it is, but by how it was deposited, which dictates its atomic structure, purity, and performance.

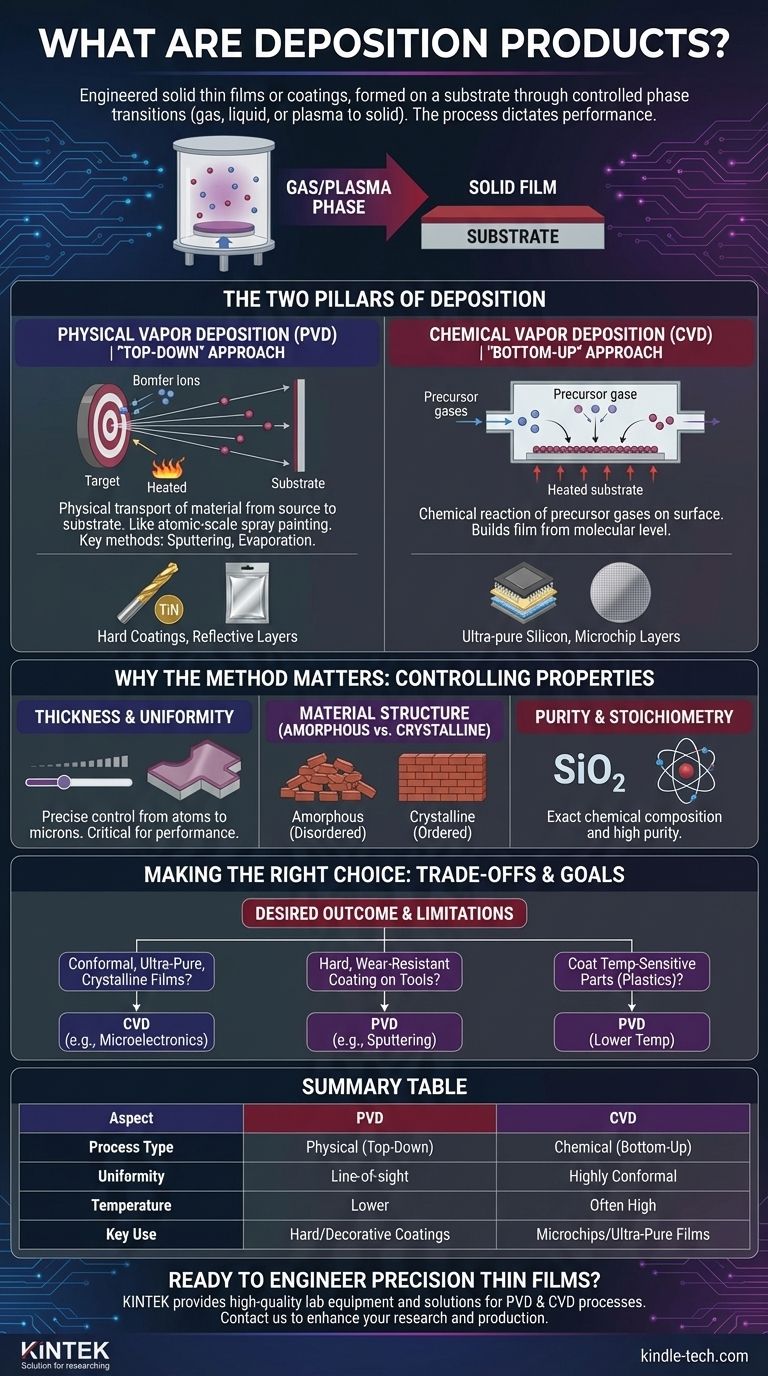

The Two Pillars of Deposition: PVD and CVD

Nearly all advanced deposition products are created using one of two core methodologies: Physical Vapor Deposition (PVD) or Chemical Vapor Deposition (CVD). Understanding the difference is critical to understanding the product itself.

Physical Vapor Deposition (PVD): The "Top-Down" Approach

PVD works by physically moving material from a source (a "target") to the substrate. Imagine it as a form of atomic-scale spray painting.

The two main PVD methods are sputtering and evaporation. In sputtering, high-energy ions bombard the target, knocking atoms loose, which then travel and coat the substrate. In evaporation, the source material is heated in a vacuum until it vaporizes, and this vapor condenses on the cooler substrate.

Common PVD products include the hard, gold-colored titanium nitride (TiN) coatings on drill bits or the thin metal layers that give potato chip bags their reflective interior.

Chemical Vapor Deposition (CVD): The "Bottom-Up" Approach

CVD is a chemical process. It builds the film atom-by-atom from reactive gases known as "precursors."

These precursor gases are introduced into a reaction chamber where they decompose and react on the heated substrate's surface, leaving behind the desired solid material. Think of it like frost forming on a cold window, where water vapor (the precursor) turns directly into a solid crystal layer (the ice).

CVD is essential for creating the ultra-pure silicon and silicon dioxide layers that form the basis of all modern microchips.

Why the Deposition Method Matters

The choice between PVD, CVD, or their many variants is a deliberate engineering decision. The method directly controls the final properties of the deposition product.

Controlling Thickness and Uniformity

Deposition processes allow for incredible precision. By controlling parameters like time, temperature, and gas pressure, engineers can create films of a specific thickness, from a few atoms to many microns, with remarkable uniformity across the substrate's surface.

This control is non-negotiable for products like optical filters or semiconductor wafers, where even tiny variations in thickness can lead to complete device failure.

Defining Material Structure (Amorphous vs. Crystalline)

The deposition conditions, especially temperature, determine how the atoms arrange themselves.

A crystalline structure is highly ordered, like a perfectly stacked wall of bricks. This often leads to specific electronic or optical properties. In contrast, an amorphous structure is disordered, like a pile of bricks, which can be desirable for creating smooth, uniform surfaces.

Ensuring Purity and Stoichiometry

The final product must have the correct chemical composition, or stoichiometry. For example, a silicon dioxide (SiO₂) film must have exactly two oxygen atoms for every one silicon atom.

CVD excels at producing high-purity, stoichiometric films because it builds them from precise chemical reactions. However, both PVD and CVD are performed in vacuum chambers to minimize contamination from unwanted atmospheric gases, which would otherwise be incorporated as impurities.

Understanding the Trade-offs

Neither method is universally superior; each comes with fundamental trade-offs that make them suitable for different applications.

PVD: Line-of-Sight and Lower Temperatures

PVD is fundamentally a line-of-sight process. The sputtered or evaporated atoms travel in straight lines, making it difficult to evenly coat complex, three-dimensional shapes with hidden surfaces.

However, many PVD processes can run at lower temperatures than CVD. This makes PVD ideal for coating heat-sensitive materials, such as plastics or previously fabricated electronic components.

CVD: Conformality vs. High Heat and Hazards

CVD is not limited by line-of-sight and can produce highly conformal coatings that uniformly cover even the most complex 3D structures. This is a major advantage in microfabrication.

The primary drawback is heat. Many CVD processes require very high temperatures that the substrate may not be able to withstand. Furthermore, the precursor gases used are often highly toxic, flammable, or corrosive, requiring extensive and costly safety infrastructure.

Making the Right Choice for Your Goal

The ideal deposition method is determined entirely by the desired properties of your final product and the physical and chemical limitations of your substrate.

- If your primary focus is creating ultra-pure, conformal crystalline films for electronics: CVD is often the superior choice due to its precise control over chemical reactions at the atomic level.

- If your primary focus is applying a hard, wear-resistant coating onto metal tools or parts: PVD processes like sputtering are more practical, often lower temperature, and highly effective.

- If your primary focus is metallizing a temperature-sensitive plastic part for decorative or shielding purposes: PVD is the clear choice because its lower processing temperatures will not melt or damage the substrate.

Ultimately, understanding deposition is about mastering the process to engineer the exact material properties you need.

Summary Table:

| Aspect | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Process Type | Physical (e.g., sputtering, evaporation) | Chemical (gas-phase reactions) |

| Coating Uniformity | Line-of-sight; less conformal | Highly conformal; covers complex 3D shapes |

| Temperature Requirements | Lower temperatures; suitable for heat-sensitive substrates | Often high temperatures; may damage sensitive materials |

| Common Applications | Hard coatings (e.g., TiN on tools), decorative metallization | Microchips, ultra-pure silicon layers, optical films |

| Key Advantages | Lower heat, simpler for flat surfaces | High purity, precise stoichiometry, excellent conformality |

Ready to engineer precision thin films for your lab?

At KINTEK, we specialize in providing high-quality lab equipment and consumables for deposition processes, including PVD and CVD systems. Whether you're developing microelectronics, advanced optics, or durable coatings, our solutions ensure precise control over thickness, purity, and material structure.

Contact us today to discuss how our expertise can enhance your research and production outcomes!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is Medium Temperature Chemical Vapour Deposition (MTCVD) used for? Enhance Tool Life & Performance

- What is the effect of pressure on graphene? Unlock Tunable Strength and Electronics

- What is low power chemical vapor deposition? Discover LPCVD for Superior Thin-Film Quality

- What is the temperature range for CVD? It's Not a Single Number—It's Dictated by Your Materials

- What are thin films used for? Enhance Durability, Optics, and Electronics

- What is the disadvantage of sputtering? Navigating Speed, Cost, and Material Limitations

- Why is a high-precision vacuum pump system essential for iCVD? Achieve Superior Film Purity and Uniformity

- What role does substrate heating play in superalloy CVD coatings? Unlock Precision Microstructure & Superior Adhesion