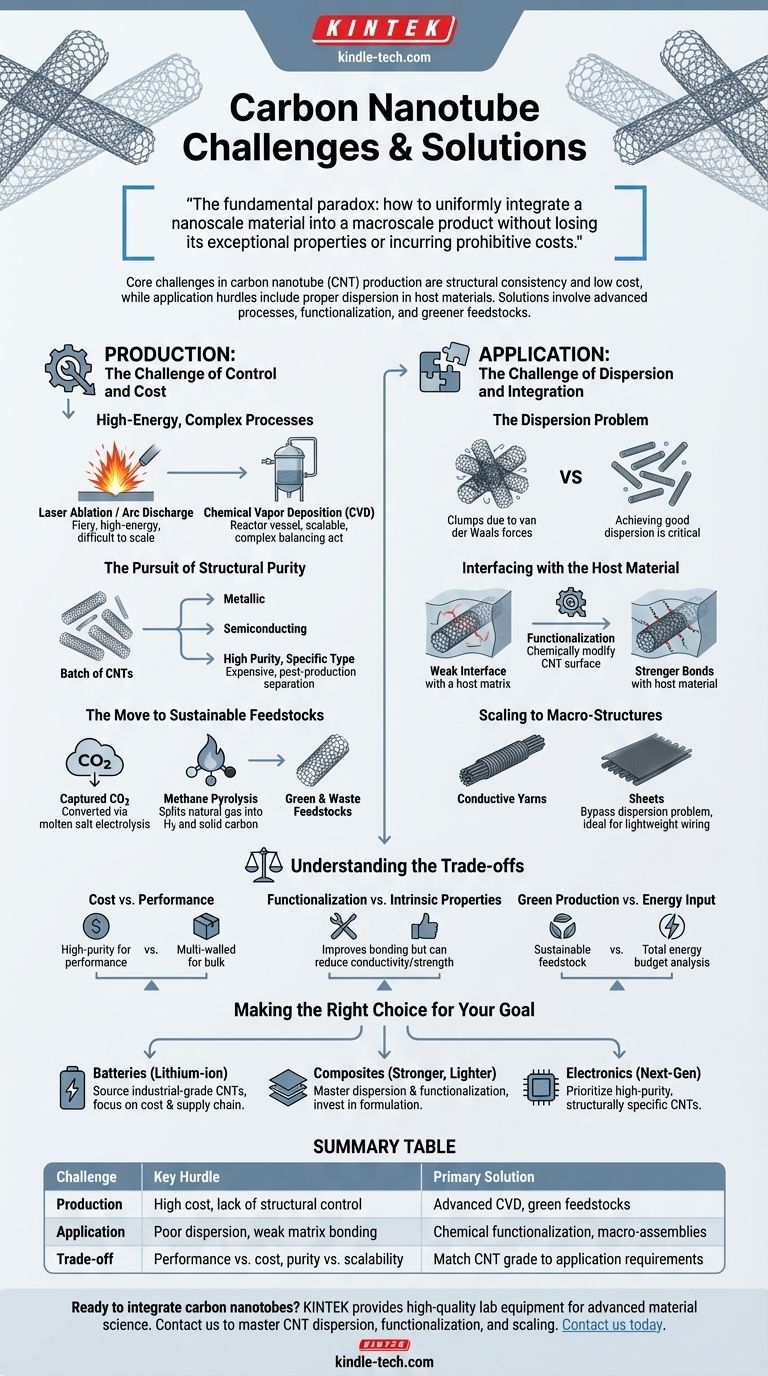

At their core, the primary challenges in carbon nanotube (CNT) production are achieving structural consistency at a low cost, while the main hurdle in their application is properly dispersing these microscopic tubes within a larger material. Overcoming these challenges involves a combination of advanced manufacturing processes like chemical vapor deposition (CVD), chemical modifications known as functionalization, and the development of new, greener feedstocks.

While carbon nanotubes offer revolutionary potential for materials science, their practical success hinges on solving a fundamental paradox: how to uniformly integrate a nanoscale material into a macroscale product without losing its exceptional properties or incurring prohibitive costs.

Production: The Challenge of Control and Cost

The promise of CNTs is dictated by their structure—diameter, length, and chirality (the angle of the atomic lattice). Producing the exact structure needed for a specific application, repeatably and affordably, remains the central manufacturing challenge.

High-Energy, Complex Processes

Traditional methods like laser ablation and arc discharge create high-quality CNTs but are energy-intensive and difficult to scale. These processes are analogous to creating diamonds with immense heat and pressure—effective, but not economical for bulk materials.

The industry has largely shifted to Chemical Vapor Deposition (CVD), a more scalable process where a carbon-containing gas is broken down at high temperatures. While CVD is the dominant commercial method, controlling the final CNT structure within the reactor is still a complex balancing act of temperature, pressure, and catalyst chemistry.

The Pursuit of Structural Purity

The biggest difficulty is consistently producing CNTs of a specific type. A batch of CNTs often contains a mixture of different structures, some metallic and some semiconducting, which can be detrimental for sensitive applications like electronics. Separating these is a costly, post-production process.

The Move to Sustainable Feedstocks

A significant area of innovation is the shift away from traditional hydrocarbon gases. Emerging methods focus on using "green" or waste feedstocks to lower both the cost and environmental impact of production.

This includes using captured carbon dioxide, which is converted into CNTs via electrolysis in molten salts, or using methane pyrolysis, which splits natural gas into hydrogen and solid carbon, forming CNTs in the process.

Application: The Challenge of Dispersion and Integration

Once you have CNTs, you face an even greater challenge: getting them to work inside another material, such as a polymer, metal, or battery electrode.

The Dispersion Problem

Due to powerful attractive forces (van der Waals forces), individual carbon nanotubes instinctively clump together, or agglomerate. A clump of CNTs behaves more like a simple carbon particle, negating the benefits of the high aspect ratio and surface area of individual tubes.

Achieving good dispersion—separating these clumps and distributing the tubes evenly throughout a host material—is the single most critical factor for success in most composite applications.

Interfacing with the Host Material

Even if perfectly dispersed, the CNTs must form a strong bond with the surrounding matrix material (e.g., a polymer resin). A weak interface means that stress or electrical energy cannot be transferred effectively from the matrix to the nanotube, rendering the additive useless.

This is solved through functionalization, a process that chemically modifies the surface of the CNTs to make them more compatible with the host material, allowing them to form stronger bonds.

Scaling to Macro-Structures

Bridging the gap from a powder to a usable product is a major focus. Innovations include forming highly conductive continuous yarns and sheets directly from CNTs. These "macro-CNTs" bypass the dispersion problem by pre-assembling the nanotubes into a usable format, ideal for applications like lightweight wiring or thermal films.

Understanding the Trade-offs

Deploying CNTs effectively requires balancing competing priorities. There are no perfect solutions, only choices optimized for a specific goal.

Cost vs. Performance

High-purity, single-walled CNTs with perfect structures offer the best theoretical performance but are exceptionally expensive. For bulk applications like conductive polymers or concrete, lower-cost, multi-walled CNTs provide a significant property enhancement for a commercially viable price. The key is matching the grade of the CNT to the value it adds.

Functionalization vs. Intrinsic Properties

The chemical processes used for functionalization can create defects in the nanotube's carbon lattice. While this improves dispersion and bonding, it can slightly reduce the CNT's intrinsic strength or electrical conductivity. The goal is to find the minimum level of functionalization needed to achieve good integration without sacrificing core properties.

Green Production vs. Energy Input

Using waste CO2 or methane as a feedstock is a major step toward sustainability. However, one must analyze the entire energy budget. Processes like molten salt electrolysis are energy-intensive, and the source of that electricity—whether from renewables or fossil fuels—determines the true "green" credentials of the final product.

Making the Right Choice for Your Goal

The right strategy depends entirely on your end-use application.

- If your primary focus is improving lithium-ion batteries: Concentrate on sourcing industrial-grade CNTs as a conductive additive, as this is a mature and proven application. The main challenges are cost-competitiveness and supply chain logistics.

- If your primary focus is creating stronger, lighter, or conductive composites: Your success will depend entirely on mastering dispersion and functionalization. Invest in formulation expertise, not just the raw material.

- If your primary focus is developing next-generation electronics or sensors: You must prioritize obtaining high-purity, structurally specific CNTs. The challenge here is less about cost and more about accessing materials with the precise electronic properties you require.

Ultimately, the successful application of carbon nanotubes is a game of mastering the interface between the nano-world and our macro-world.

Summary Table:

| Challenge | Key Hurdle | Primary Solution |

|---|---|---|

| Production | High cost, lack of structural control | Advanced CVD processes, green feedstocks (CO2, methane) |

| Application | Poor dispersion, weak matrix bonding | Chemical functionalization, macro-assemblies (yarns, sheets) |

| Trade-off | Performance vs. cost, purity vs. scalability | Match CNT grade to application requirements |

Ready to integrate carbon nanotubes into your lab's research or products? KINTEK specializes in providing high-quality lab equipment and consumables tailored for advanced material science. Whether you're developing next-generation batteries, composites, or sensors, our expertise ensures you have the right tools to master CNT dispersion, functionalization, and scaling. Contact us today to explore how KINTEK can support your laboratory's innovation in nanotechnology and beyond!

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition