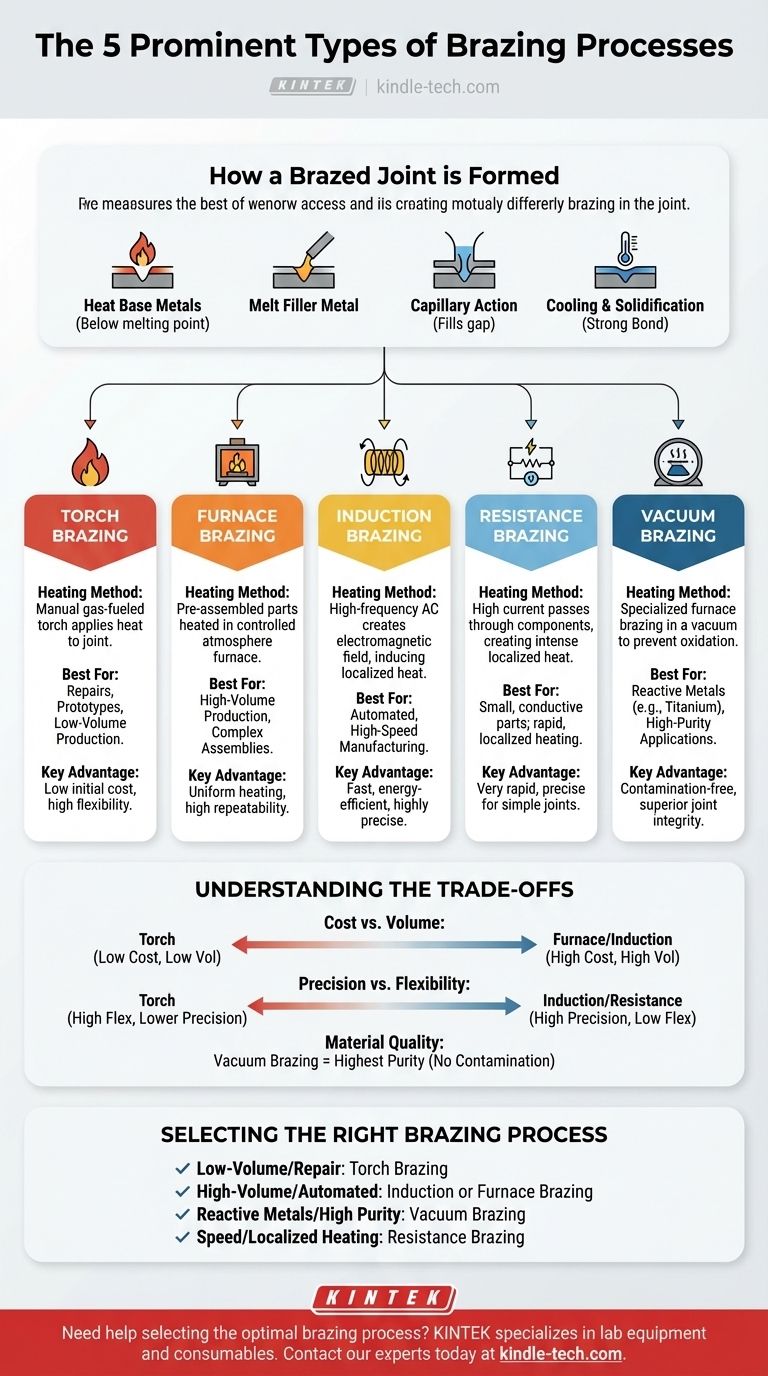

While there are more than five common methods, the five most prominent types of brazing are defined by their method of heating: Torch, Furnace, Induction, Resistance, and Vacuum brazing. Each technique uses heat to melt a filler metal into a joint, but the way that heat is generated and applied dictates the process's suitability for different materials, production volumes, and quality requirements.

The "best" brazing process does not exist in isolation. The optimal choice is always a function of matching the heating method to the specific demands of your application, balancing factors like production volume, material sensitivity, joint complexity, and cost.

How a Brazed Joint is Formed

Before comparing methods, it's crucial to understand the fundamental principle they all share. Brazing joins materials without melting them.

The Role of Heat and Filler Metal

All brazing involves heating the base metals to a temperature that is below their melting point but above the melting point of a dissimilar filler metal.

When the filler metal melts, it is drawn into the tight-fitting gap between the base materials by a phenomenon called capillary action, creating a strong, metallurgical bond as it cools and solidifies.

The Critical Temperature Window

The process occurs within a precise temperature range. For example, when brazing aluminum, the flux may melt around 565°C to clean the surface, with the filler metal melting and flowing just above that, around 577°C.

This principle holds true for all brazing: the goal is to be hot enough to melt the filler but cool enough to preserve the integrity of the parts being joined. The key differentiator between brazing types is how this heat is delivered.

The Primary Brazing Processes (Methods of Heating)

Each process offers a distinct approach to applying heat, making each one suited for different scenarios.

Torch Brazing

This is the most common and versatile method, often performed manually with a gas-fueled torch. An operator heats the base metals and then introduces the filler metal to the joint.

It is highly flexible, requires low initial investment, and is ideal for repairs, prototypes, and low-volume production runs.

Furnace Brazing

In this process, parts are pre-assembled with the filler metal placed at the joint. The entire assembly is then placed into a furnace and heated in a controlled atmosphere.

This method is excellent for high-volume production and complex assemblies with multiple joints, as it ensures uniform heating and high repeatability.

Induction Brazing

Induction brazing uses a high-frequency alternating current passed through a coil to create an electromagnetic field. This field induces an electrical current in the parts, rapidly generating localized heat precisely at the joint area.

This process is extremely fast, energy-efficient, and highly controllable, making it perfect for automated, high-speed manufacturing lines.

Resistance Brazing

This method uses the components themselves as part of an electrical circuit. High current is passed through the parts, and the resistance to this current flow generates intense, localized heat at the joint.

It is a very rapid process, well-suited for joining small, electrically conductive components where heat must be applied quickly and precisely.

Vacuum Brazing

A specialized form of furnace brazing, this process takes place inside a vacuum chamber. By removing the atmosphere, it prevents the formation of oxides on the metal surfaces.

This is critical for joining reactive materials like titanium and aluminum, or for high-purity applications in the aerospace and medical industries where joint integrity cannot be compromised.

Understanding the Trade-offs

Choosing a brazing process involves balancing competing priorities. No single method is superior in all situations.

Cost vs. Volume

Torch brazing has the lowest initial cost but the highest per-piece labor cost, making it unsustainable for large volumes.

Conversely, furnace and induction brazing require a significant capital investment in equipment but offer a very low cost per piece in high-volume production due to automation and efficiency.

Precision vs. Flexibility

Manual torch brazing offers maximum flexibility but relies heavily on operator skill for precision and consistency.

Induction and resistance brazing provide exceptional precision and repeatability, but the equipment is specialized for a specific joint geometry and is less flexible for varied tasks.

Material and Joint Quality

For standard metals like steel or copper in non-critical applications, most methods work well. However, for reactive metals or applications demanding zero contamination, the choice narrows.

Vacuum brazing is often the only option for achieving the highest possible joint purity and strength, as it eliminates the risk of atmospheric contamination that can weaken the bond.

Selecting the Right Brazing Process

Your choice depends entirely on your project's constraints and goals.

- If your primary focus is low-volume production or repair: Torch brazing is the most practical and cost-effective choice.

- If your primary focus is high-volume, automated manufacturing: Induction or furnace brazing offers the best repeatability and efficiency.

- If your primary focus is joining reactive metals or achieving the highest joint purity: Vacuum brazing is non-negotiable for its superior, contamination-free results.

- If your primary focus is speed and localized heating on simple joints: Resistance brazing provides a rapid and targeted solution for conductive parts.

Understanding these heating methods empowers you to select the process that delivers the required quality, speed, and cost-effectiveness for your specific application.

Summary Table:

| Brazing Process | Best For | Key Advantage |

|---|---|---|

| Torch Brazing | Repairs, prototypes, low volume | Low initial cost, high flexibility |

| Furnace Brazing | High-volume, complex assemblies | Uniform heating, high repeatability |

| Induction Brazing | Automated, high-speed manufacturing | Fast, energy-efficient, precise |

| Resistance Brazing | Small, conductive parts | Rapid, localized heating |

| Vacuum Brazing | Reactive metals, high-purity applications | Contamination-free, superior joint integrity |

Need help selecting the optimal brazing process for your laboratory or production line? KINTEK specializes in lab equipment and consumables, serving all your brazing and thermal processing needs. Our experts can help you match the right heating method to your materials, volume, and quality requirements. Contact us today to discuss your application and discover how our solutions can enhance your process efficiency and joint quality.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Can aluminum and steel be brazed? Master the Metallurgical Challenges for a Strong Joint

- What is vacuum quenching? Achieve Maximum Hardness with a Clean, Oxidation-Free Finish

- What is the role of a laboratory vacuum arc remelting furnace? Mastering High-Entropy Alloy Synthesis

- How do vacuum furnaces heat? Achieve Purity and Precision in High-Temperature Processing

- What is the primary function of a resistance heating furnace? Master Magnesium Purification via Vacuum Sublimation

- Why is a high vacuum system necessary when measuring the hydrogen solubility of aluminum? Ensure Data Purity

- Why is graphite generally used as a refractory material for lining electric furnaces? Unmatched Performance & Efficiency

- Why is a high-vacuum environment necessary for sintering aluminum composites? Achieve Superior Bonding & Density