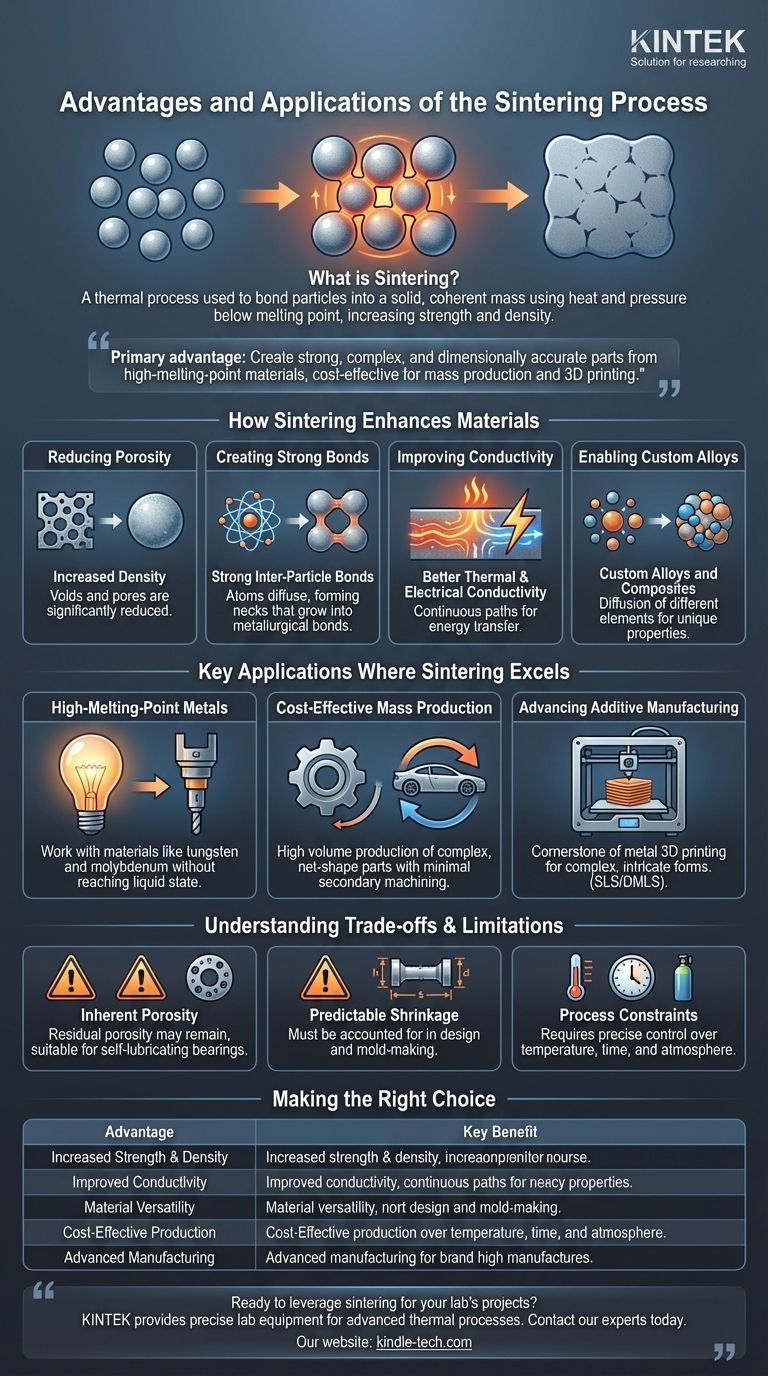

At its core, sintering is a thermal process used to bond particles of metal, ceramic, or plastic into a solid, coherent mass. It accomplishes this using heat and pressure at temperatures below the material's melting point, fundamentally increasing the material's strength, density, and other critical properties by creating strong bonds where individual particles once touched.

The primary advantage of sintering is its ability to create strong, complex, and dimensionally accurate parts from materials with extremely high melting points, making it a cost-effective solution for mass production and advanced applications like 3D printing.

How Sintering Fundamentally Enhances Materials

Sintering is not simply about heating a powder; it is a controlled process that fundamentally alters the material's microstructure to achieve desired engineering properties.

Reducing Porosity for Increased Density

The initial material, a compacted powder, is filled with tiny voids or pores between particles. The sintering process dramatically reduces the volume of these pores.

As particles bond and draw closer, the overall density of the part increases, which is directly linked to improvements in strength and conductivity.

Creating Strong Inter-Particle Bonds

During sintering, atoms diffuse across the boundaries of adjacent particles, forming "necks" that grow into strong metallurgical bonds.

This is the primary mechanism for increasing the material's strength and integrity, transforming a fragile powder compact into a durable, functional component.

Improving Thermal and Electrical Conductivity

Pores within a material act as insulators, impeding the flow of heat and electricity. By eliminating these voids, sintering creates a more continuous path for energy transfer.

This results in significantly improved thermal and electrical conductivity, a critical requirement for many electronic and high-temperature applications.

Enabling Custom Alloys and Composites

Sintering allows for the diffusion of different elements within the part. Powders of different metals, such as nickel, copper, or graphite, can be blended before compaction.

During the heating process, these elements diffuse into the base material, creating unique alloys and composites with tailored properties that would be difficult to achieve through melting.

Key Applications Where Sintering Excels

The unique benefits of sintering make it the ideal, and sometimes only, choice for a range of demanding manufacturing scenarios.

Working with High-Melting-Point Metals

Materials like tungsten and molybdenum have melting points so high that melting and casting them is impractical and prohibitively expensive.

Sintering allows for the creation of dense, strong parts from these materials without ever reaching their liquid state, making it essential for products like industrial tooling and light bulb filaments.

Cost-Effective Mass Production of Complex Parts

Sintering is highly effective for producing large volumes of parts with high repeatability and accuracy. It can create complex, non-machinable geometries in their final "net-shape" form.

This often eliminates the need for expensive and time-consuming secondary machining operations, providing a significant cost advantage at scale.

Advancing Additive Manufacturing (3D Printing)

Sintering is a cornerstone of metal 3D printing processes like Selective Laser Sintering (SLS) and Direct Metal Laser Sintering (DMLS).

In these methods, a laser selectively sinters layers of fine metal powder to build a part from the ground up, enabling the creation of custom, incredibly intricate forms that are impossible with any other method.

Understanding the Trade-offs and Limitations

While powerful, sintering is not a universal solution. Acknowledging its limitations is crucial for making an informed decision.

Inherent Porosity

Although sintering drastically reduces porosity, it rarely eliminates it completely. For applications requiring absolute, 100% density to prevent fracture, processes like forging or casting may be more suitable. However, this residual porosity can be an advantage for applications like self-lubricating bearings or filters.

Predictable Shrinkage

As a part becomes denser during sintering, it shrinks. This shrinkage is predictable and must be precisely accounted for during the initial design and mold-making stages to ensure the final part meets dimensional specifications.

Process and Material Constraints

The sintering process requires precise control over temperature, time, and atmospheric conditions to prevent oxidation and ensure proper bonding. Furthermore, not all materials are suitable for sintering, as the process relies on the specific diffusion characteristics of the material's atoms.

Making the Right Choice for Your Goal

To determine if sintering is the correct approach, consider your primary objective.

- If your primary focus is cost-effective mass production of complex metal parts: Sintering is an excellent choice for achieving net-shape geometries with high repeatability, minimizing the need for secondary machining.

- If your primary focus is working with high-performance materials like tungsten or ceramics: Sintering is often the only viable manufacturing method, as it avoids the extreme temperatures and challenges associated with melting.

- If your primary focus is creating custom prototypes or intricate one-off designs: Sintering-based 3D printing offers unparalleled design freedom compared to traditional manufacturing methods.

- If your primary focus is achieving maximum theoretical strength with zero porosity: You may need to consider alternative processes like casting or forging, as some residual porosity can remain after sintering.

By understanding its core principles, you can leverage sintering to solve manufacturing challenges that are otherwise out of reach.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Increased Strength & Density | Reduces porosity, creates strong inter-particle bonds. |

| Improved Conductivity | Enhances thermal and electrical properties. |

| Material Versatility | Enables custom alloys and composites. |

| Cost-Effective Production | Ideal for mass production of complex, net-shape parts. |

| Advanced Manufacturing | Core technology for metal 3D printing (SLS/DMLS). |

Ready to leverage sintering for your lab's projects? KINTEK specializes in providing the precise lab equipment and consumables needed for advanced thermal processes like sintering. Whether you are developing new materials, producing complex parts, or advancing additive manufacturing, our solutions ensure accuracy, repeatability, and performance. Contact our experts today to discuss how we can support your specific laboratory needs and help you achieve superior results.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- Spark Plasma Sintering Furnace SPS Furnace

People Also Ask

- What is the importance of physical vapor deposition? Enhance Material Performance with High-Performance Coatings

- What is the process of soaking during heat treatment? Achieve Uniform Microstructure for Superior Metal Properties

- Why is temperature excursion alarming important in ultra-low freezers? Protect Your Valuable Samples from Catastrophic Loss

- What is the origin of sintering? Discover the Prehistoric Evolution of Thermal Fusion and Ancient Ceramics

- What is the powder sintering process? A Guide to Net-Shape Manufacturing

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout

- What is high-temperature sintering method? Boost Strength & Durability with Advanced Thermal Processing

- What is potassium bromide made of? Discover the Ionic Compound Powering Labs and Veterinary Care