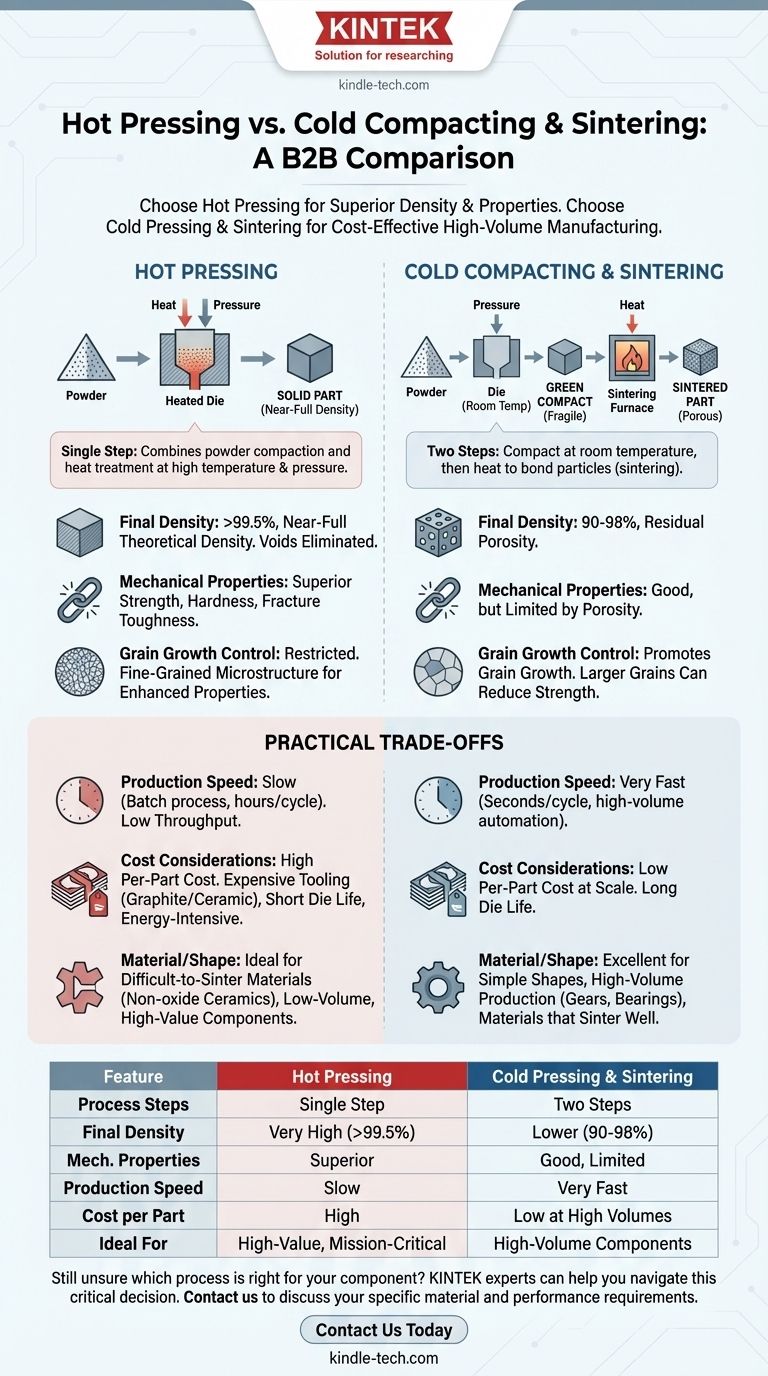

In short, hot pressing produces parts with superior density and mechanical properties, while cold pressing and sintering offers a far more cost-effective and scalable solution for high-volume manufacturing. Hot pressing combines powder compaction and heat treatment into a single step, using pressure at high temperatures to achieve nearly full densification. Conversely, the conventional method involves two distinct steps: compacting powder at room temperature (cold pressing) and then heating the resulting part to bond the particles together (sintering).

The fundamental choice between these two methods comes down to a trade-off between ultimate material performance and manufacturing efficiency. Hot pressing prioritizes quality by eliminating porosity, whereas cold pressing and sintering prioritizes speed, scalability, and lower per-part costs.

The Fundamental Difference: Combining or Separating Steps

To understand the advantages of each process, we must first examine how they fundamentally differ in their approach to turning powder into a solid object.

How Cold Pressing & Sintering Works

This is the conventional, two-step workhorse of the powder metallurgy industry.

First, metal or ceramic powder is poured into a die and compacted under high pressure at room temperature. This creates a fragile, lightly bonded part called a "green compact."

Next, this green compact is ejected and heated in a controlled-atmosphere furnace to a temperature below its melting point. This sintering step causes the individual particles to bond and diffuse into one another, increasing strength and density.

How Hot Pressing Works

Hot pressing streamlines this into a single, integrated process.

Powder is placed into a die (typically made of graphite or ceramic) that can withstand extreme heat. The die is heated while pressure is simultaneously applied.

This combination of heat and pressure dramatically accelerates densification, allowing for the creation of a solid part in a single operation. The pressure helps collapse pores and rearrange particles while the heat facilitates atomic diffusion and bonding.

Comparing Key Performance Outcomes

The differences in process lead to significant variations in the final material's characteristics.

Final Density and Porosity

Hot pressing consistently achieves near-full theoretical density (often >99.5%). The applied pressure actively forces out voids and porosity during the thermal cycle.

Cold pressing and sintering almost always leaves some residual porosity in the final part. Typical densities range from 90-98%, which can be a limiting factor for high-stress applications.

Mechanical Properties

Mechanical performance is directly linked to density. Because hot-pressed parts are virtually pore-free, they exhibit significantly higher strength, hardness, and fracture toughness compared to their sintered counterparts. Pores act as stress concentration points and potential failure initiation sites.

Grain Growth Control

Sintering requires high temperatures and often extended times to achieve good bonding, which promotes grain growth. Larger grains can reduce a material's strength and hardness.

Hot pressing allows for the use of lower temperatures and much shorter processing times to achieve full density. This effectively restricts grain growth, resulting in a fine-grained microstructure that further enhances mechanical properties.

Understanding the Practical Trade-offs

While hot pressing delivers superior material quality, it comes with significant operational disadvantages that make it unsuitable for many applications.

Production Speed and Scalability

Cold pressing is extremely fast, with cycle times often measured in seconds per part, making it ideal for high-volume, automated production of thousands or millions of components.

Hot pressing is a slow, batch process. Cycle times can range from 30 minutes to several hours. This low throughput makes it unsuitable for mass production and reserves it for low-volume, high-value components.

Cost Considerations

The tooling for cold pressing is designed for high-speed operation at room temperature and, while expensive initially, has a long life, leading to a very low per-part cost at scale.

Hot pressing requires expensive die materials like graphite or ceramics that can withstand both high pressure and temperature. These dies have a much shorter lifespan and are more costly to manufacture, significantly increasing the per-part cost. The process is also more energy-intensive.

Material and Shape Limitations

Hot pressing is essential for consolidating materials that are very difficult to sinter, such as non-oxide ceramics (e.g., silicon carbide) or certain metal matrix composites.

Cold pressing excels at producing relatively simple shapes in large quantities. Complex geometries can be challenging to press uniformly, and the process is best suited for materials that sinter well, such as steels and copper alloys.

Making the Right Choice for Your Application

Selecting the correct process requires a clear understanding of your project's primary goal.

- If your primary focus is maximum performance and density: Choose hot pressing. It is the superior choice for mission-critical components, advanced ceramics, and materials where any porosity is unacceptable.

- If your primary focus is high-volume production and cost-efficiency: Choose cold pressing and sintering. This is the undisputed standard for manufacturing gears, bearings, and structural components for the automotive and industrial sectors.

- If your primary focus is achieving the finest possible grain structure: Choose hot pressing. Its lower processing temperatures and shorter cycles are ideal for creating materials with superior microstructural integrity.

By understanding the core trade-off between integrated performance and scalable production, you can confidently select the powder metallurgy process that aligns perfectly with your engineering and business goals.

Summary Table:

| Feature | Hot Pressing | Cold Pressing & Sintering |

|---|---|---|

| Process Steps | Single step (heat + pressure) | Two steps (press, then sinter) |

| Final Density | Very high (>99.5%), near-full density | Lower (90-98%), some porosity |

| Mechanical Properties | Superior strength, hardness, toughness | Good, but limited by porosity |

| Production Speed | Slow (batch process, hours/cycle) | Very fast (seconds/cycle, high-volume) |

| Cost per Part | High (expensive tooling, energy-intensive) | Low at high volumes (cost-effective) |

| Ideal For | High-value, mission-critical parts, advanced ceramics | High-volume components (gears, bearings) |

Still unsure which process is right for your component? The experts at KINTEK can help you navigate this critical decision. We specialize in providing the lab equipment and consumables needed for both R&D and production-scale powder metallurgy.

Contact us today to discuss your specific material and performance requirements, and let us help you achieve optimal results for your laboratory or manufacturing needs.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What is the significance of precise temperature control in melt infiltration? Achieve High-Performance Li-Alloy Electrodes

- What role does a high-temperature hot press play in the sintering of NITE-SiC? Optimize Your Densification Process

- What are the advantages of using a vacuum hot press sintering furnace? Achieve 99.1% Density in CuW30 Composites

- Why is precise temperature control necessary for SiC/Cu Vacuum Hot Pressing? Mastering the Cu9Si Interface Phase

- What conditions does a Vacuum Hot Pressing Furnace provide for Copper-MoS2-Mo composites? Achieve Peak Densification