In the context of laboratory and small-scale operations, a filter press offers exceptional control and versatility for solid-liquid separation. Its primary advantages are its low cost and the high degree of process control it provides, making it ideal for research and development. However, these benefits come at the cost of limited capacity and a reliance on manual operation, which makes it unsuitable for high-volume production.

A laboratory filter press is an invaluable tool for process development and small-batch filtration, providing precision and flexibility. Its fundamental trade-off, however, is sacrificing high-volume throughput and automation for granular control and lower initial investment.

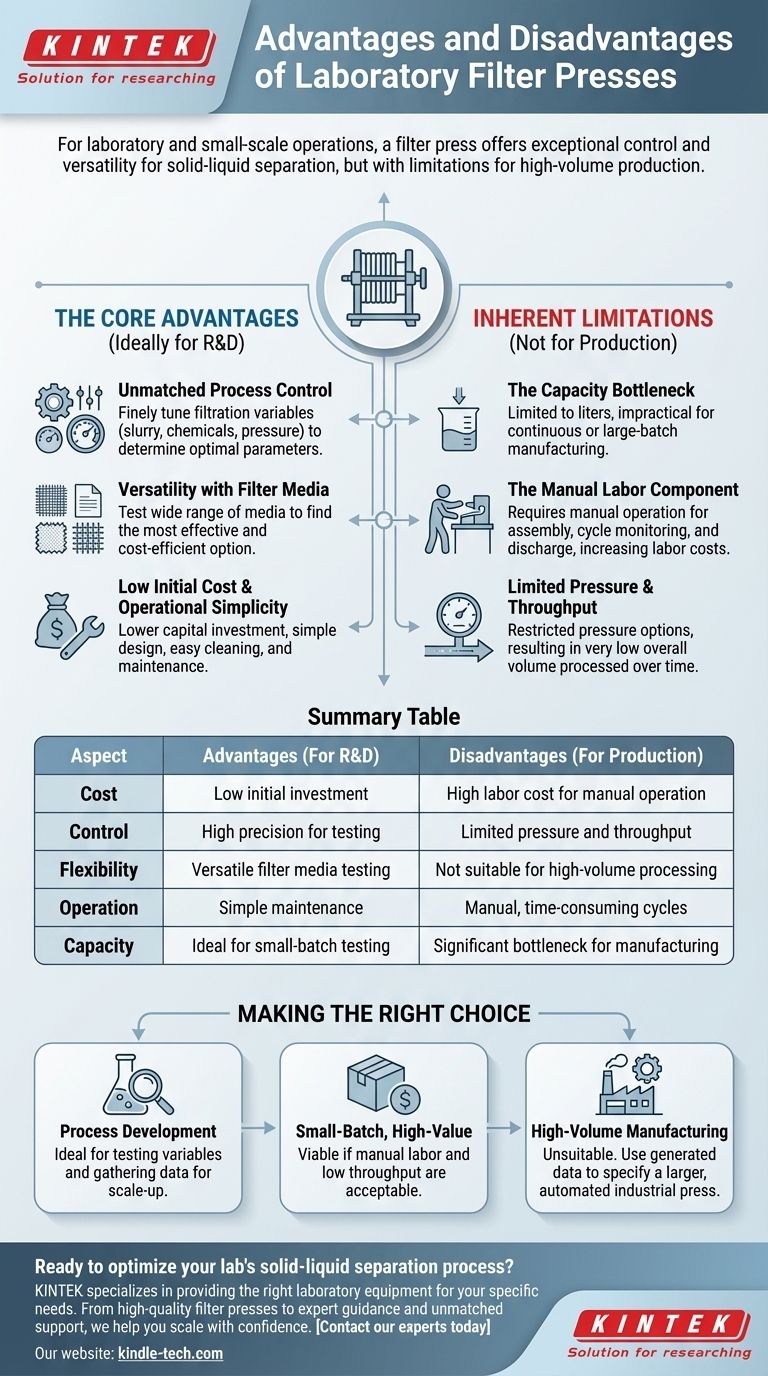

The Core Advantages of a Laboratory Filter Press

A lab-scale filter press is designed for precision and experimentation, not mass production. Its benefits directly reflect this purpose.

Unmatched Process Control

A key advantage is the ability to finely tune the filtration process. You can easily experiment with different variables like slurry concentrations, pre-treatment chemicals, and operating pressures.

This level of control is critical during the research and development phase to determine optimal filtration parameters before scaling up.

Versatility with Filter Media

These presses are not locked into a single type of filter. You can test a wide variety of filter media, from different cloth weaves to paper grades.

This versatility allows you to identify the most effective and cost-efficient medium for a specific slurry, which is a crucial data point for process design.

Low Initial Cost and Operational Simplicity

Compared to industrial-scale equipment, a laboratory press has a much lower capital cost, making it accessible for labs and pilot plants.

Their design is mechanically simple, which translates to straightforward operation and ease of cleaning and maintenance. This reduces downtime and the need for specialized technicians.

Understanding the Inherent Limitations

The strengths of a lab filter press in a research setting become its primary disadvantages when considering larger-scale applications.

The Capacity Bottleneck

By design, these presses have a limited capacity. They are intended for filtering small volumes, typically in the range of liters, not cubic meters.

This makes them completely impractical for any continuous or large-batch manufacturing process, where they would quickly become a significant bottleneck.

The Manual Labor Component

Most laboratory filter presses require manual operation. This includes assembly, monitoring the cycle, and manually opening the press to discharge the filter cake.

While acceptable for a few tests per day, this becomes extremely time-consuming and labor-intensive if used for regular production, driving up operational costs.

Limited Pressure and Throughput

While offering control, lab presses often have limited pressure options compared to their industrial counterparts. This can restrict their effectiveness with highly compressible or difficult-to-filter solids.

The combination of small size and manual cycling results in very low overall throughput, which is the volume of liquid processed over time.

Making the Right Choice for Your Goal

Selecting a filter press depends entirely on your primary objective.

- If your primary focus is process development: A laboratory filter press is the ideal choice for testing variables and gathering data for scale-up.

- If your primary focus is small-batch, high-value production: It can be a viable option, provided the manual labor and low throughput are acceptable for your business model.

- If your primary focus is high-volume manufacturing: A laboratory press is unsuitable; you should use the data it generates to specify a larger, automated industrial filter press.

Ultimately, the laboratory filter press is a specialized instrument designed for knowledge generation, not for bulk material processing.

Summary Table:

| Aspect | Advantages (For R&D) | Disadvantages (For Production) |

|---|---|---|

| Cost | Low initial investment | High labor cost for manual operation |

| Control | High precision for testing variables | Limited pressure and throughput |

| Flexibility | Versatile filter media testing | Not suitable for high-volume processing |

| Operation | Simple maintenance and cleaning | Manual, time-consuming cycles |

| Capacity | Ideal for small-batch testing | Significant bottleneck for manufacturing |

Ready to optimize your lab's solid-liquid separation process?

At KINTEK, we specialize in providing the right laboratory equipment for your specific needs. Whether you're in the research and development phase and need the precision of a filter press, or you're ready to scale up with industrial solutions, our experts can help.

We provide:

- High-quality laboratory filter presses for R&D and small-batch production.

- Expert guidance to help you choose the perfect equipment for your application.

- Unmatched support to ensure your lab operations run smoothly and efficiently.

Don't let filtration challenges slow down your innovation. Use the data from a KINTEK lab press to scale your process with confidence.

Contact our experts today to discuss your project and find the ideal solution!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

People Also Ask

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System