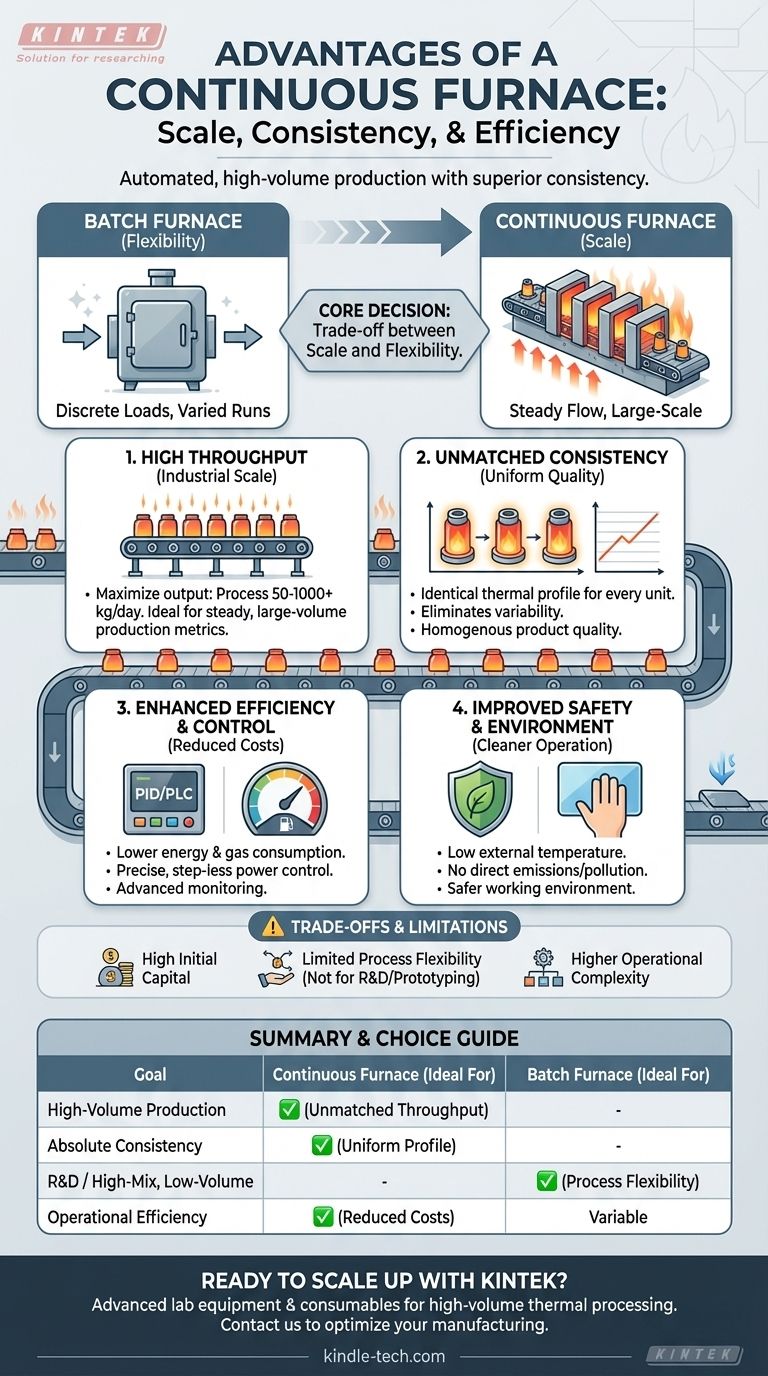

In short, the primary advantages of a continuous furnace are superior process consistency, high throughput, and greater operational efficiency. Unlike batch furnaces that process materials in discrete loads, continuous furnaces move materials through different temperature zones on a conveyor system, enabling a steady, automated production flow ideal for large-scale manufacturing.

The core decision between a continuous and a batch furnace is a trade-off between scale and flexibility. Continuous furnaces excel at producing large volumes of a single product with exceptional consistency, while batch furnaces are better suited for smaller, more varied production runs.

Unpacking the Core Advantages of Continuous Processing

Continuous furnaces are designed from the ground up for automated, high-volume production. Their benefits stem directly from this fundamental design principle of moving the product through the process, rather than bringing the process to a static product.

High Throughput for Industrial Scale

A continuous furnace is an industrial workhorse. Its design is entirely focused on maximizing output, with some systems capable of processing anywhere from 50 to over 1,000 kg of material per day.

This makes it the default choice for applications where production volume is a critical business metric and a steady stream of finished product is required.

Unmatched Product Consistency

By moving each part through an identical thermal profile, continuous furnaces eliminate the process variability common in batch systems. This ensures every single unit receives the exact same treatment.

This is often achieved through methods like a rotary tube, which constantly tumbles the material to expose its entire surface area uniformly. The result is a more homogenous product with a higher degree of quality control.

Enhanced Process Efficiency and Control

Continuous systems are highly efficient. The continuous movement improves gas diffusion during atmosphere treatments, which can significantly reduce gas consumption compared to static processes.

Furthermore, they are typically equipped with state-of-the-art process controls, using high-end PID controllers and PLCs. This allows for step-less power control, precise temperature monitoring, and highly integrated safety interlocks, all of which contribute to lower energy consumption and operational costs.

Improved Safety and Environmental Profile

Modern continuous furnaces are engineered to be clean and safe. Many designs, particularly those using induction or advanced microwave technology, produce no direct pollution or emissions.

They also feature a low external surface temperature, creating a safer and more comfortable working environment for operators.

Understanding the Trade-offs: Continuous vs. Batch Furnaces

While powerful, a continuous furnace is not the right tool for every job. Its specialized nature comes with specific limitations that are critical to understand before making an investment.

High Initial Capital Investment

The primary drawback is cost. The complex conveying systems, sophisticated zone controls, and sheer size of a continuous furnace represent a much larger upfront capital expenditure compared to a simpler batch furnace.

Lack of Process Flexibility

A continuous furnace is optimized for a specific process and product. Changing the temperature profile, residence time, or product dimensions is often a major undertaking.

This makes it ill-suited for research and development, prototyping, or high-mix, low-volume manufacturing where process parameters change frequently.

Higher Operational Complexity

The automation that provides such high throughput also requires a higher level of technical skill to operate and maintain. Calibrating conveyor speeds, managing multiple temperature zones, and servicing the control systems are more complex tasks than those associated with a basic batch furnace.

Making the Right Choice for Your Application

Selecting the correct furnace technology depends entirely on your specific production goals. The answer becomes clear when you define your primary objective.

- If your primary focus is high-volume, standardized production: A continuous furnace is the definitive choice for its unmatched throughput and automation capabilities.

- If your primary focus is absolute product consistency and quality at scale: The uniform heating and controlled processing of a continuous furnace will minimize variability and deliver a superior product.

- If your primary focus is R&D, prototyping, or producing many different products in small lots: A batch furnace provides the essential process flexibility and lower initial investment required for this type of work.

Ultimately, understanding this fundamental trade-off between production volume and process flexibility is the key to selecting the right thermal processing technology for your goals.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| High Throughput | Processes 50-1000+ kg/day | Large-scale, standardized manufacturing |

| Product Consistency | Uniform thermal profile for every unit | Applications requiring minimal quality variation |

| Operational Efficiency | Reduced energy & gas consumption, advanced process control | Lowering long-term operational costs |

| Safety & Environment | Low external temperature, no direct emissions | Cleaner, safer working environments |

Ready to scale up your production with superior consistency and efficiency?

KINTEK specializes in providing advanced lab equipment and consumables, including continuous furnaces designed for high-volume industrial thermal processing. Our solutions deliver the unmatched throughput and precise control your laboratory or production line needs to maintain a competitive edge.

Contact us today to discuss how a continuous furnace can optimize your manufacturing process and drive your business forward.

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the temperature of slow pyrolysis? Optimize for High-Quality Biochar Production

- What is the effect of calcination? Unlock Material Transformation for Industrial Processes

- How does a rotary furnace work? A Guide to Continuous Heat Processing & Mixing

- What is the effect of pyrolysis? Converting Waste into Fuel, Chemicals, and Energy

- What is the history of pyrolysis technology? From Wood Distillation to Modern Waste Valorization

- What is the effect of torrefaction on fast pyrolysis bio-oil? Achieve Higher Quality, More Stable Bio-Fuel

- What is the working principle of pyrolysis machine? Turn Waste into Energy & Resources

- What is the purpose of plastic pyrolysis? Convert Waste Plastic into Valuable Resources