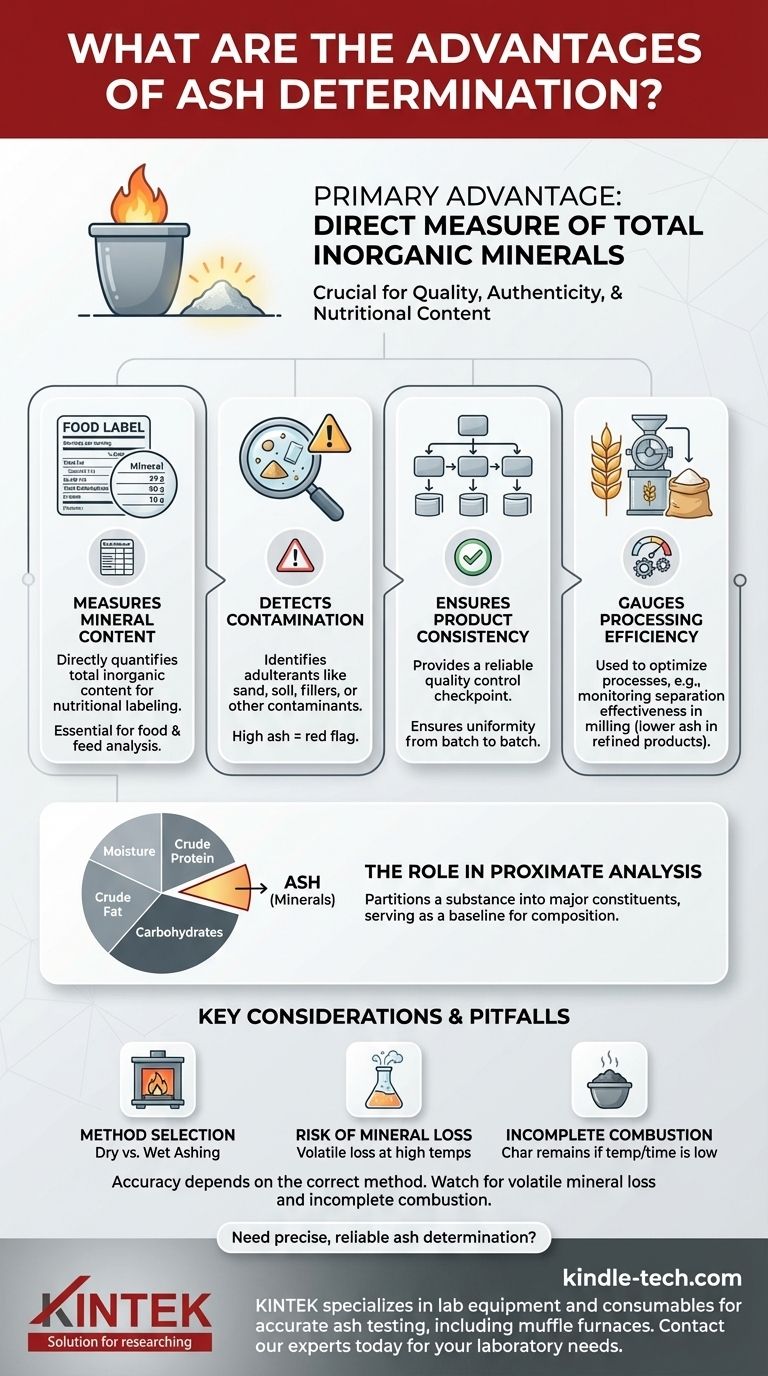

The primary advantage of ash determination is its function as a direct measure of the total amount of inorganic minerals within a product. This simple yet powerful analysis serves as a crucial indicator for quality, authenticity, and nutritional content. By burning off all organic matter, the remaining ash provides a clear metric for the non-combustible components.

Ash content is not just a number; it is a fundamental measure of a material's composition and purity. Understanding its advantages allows you to use it as a powerful tool for quality control, process optimization, and regulatory compliance.

Why Ash Content is a Critical Quality Metric

Determining the ash content of a sample is one of the most common and essential procedures in analytical chemistry. It provides a baseline understanding of a material's inorganic composition, which has significant implications for its quality and use.

A Direct Measure of Mineral Content

Ash determination is the most straightforward method for quantifying the total mineral content. This is essential for nutritional labeling in foods, where minerals are a required component of the analysis panel.

Identifying Adulteration and Contamination

An abnormally high ash content can be a clear red flag for contamination. It often indicates the presence of inorganic adulterants such as sand, soil, glass, or other fillers that have been intentionally or accidentally added to a product.

Ensuring Product Consistency

For manufacturers, consistency is key. Regularly measuring ash content helps ensure that a product meets its specifications from batch to batch, providing a reliable quality control checkpoint in the production process.

The Role of Ash in Compositional Analysis

Ash is one of the core components in a "proximate analysis," a method used to partition a substance into its major constituents: moisture, ash (minerals), crude protein, crude fat, and carbohydrates.

Gauging Processing Efficiency

In industries like flour milling, ash content is used to gauge the efficiency of the milling process. A lower ash content in refined flour indicates a more effective separation of the starchy endosperm from the mineral-rich bran and germ.

Completing the Nutritional Picture

By quantifying the mineral portion of a food or feed, ash determination provides a piece of the puzzle for a complete nutritional profile. This allows for a more accurate calculation of other components, particularly total carbohydrates.

Key Considerations and Pitfalls

While the principle is simple, the accuracy of ash determination depends entirely on using the correct method for the specific sample. The choice of method is not trivial and can significantly impact the results.

Method Selection is Crucial

The two most common methods are dry ashing (using a muffle furnace at high temperatures) and wet ashing (using liquid oxidizing agents). The appropriate choice depends on the sample type and the specific minerals of interest, as some minerals can be lost at high temperatures.

Risk of Mineral Loss

During high-temperature dry ashing, certain volatile minerals like mercury, lead, and zinc can be lost, leading to an underestimation of the true ash content. This is a critical consideration when trace mineral analysis is the ultimate goal.

Incomplete Combustion

Conversely, if the temperature is too low or the ashing time is too short, organic matter may not be completely combusted. This leaves behind carbonaceous material (char), which artificially inflates the ash weight and leads to inaccurate results.

Making the Right Choice for Your Goal

The reason for conducting an ash test will dictate your approach and how you interpret the results.

- If your primary focus is routine quality control: Use a consistent ashing method to establish a baseline for your product and quickly identify any deviations that may signal contamination or process errors.

- If your primary focus is nutritional labeling: Ash determination is your first step in quantifying the total mineral content required for a complete food analysis.

- If your primary focus is process optimization: Monitor ash content at different stages of production to measure the effectiveness of separation or purification steps.

Ultimately, ash determination is a foundational analytical technique that provides indispensable insights into a material's purity and composition.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Measures Mineral Content | Directly quantifies total inorganic content for nutritional labeling. |

| Detects Contamination | Identifies adulterants like sand, soil, or fillers. |

| Ensures Product Consistency | Provides a reliable quality control checkpoint for batch-to-batch uniformity. |

| Gauges Processing Efficiency | Helps optimize separation processes, like in flour milling. |

Need precise, reliable ash determination for your quality control or nutritional analysis? KINTEK specializes in lab equipment and consumables for accurate ash testing, including muffle furnaces for dry ashing. Our solutions help you ensure product purity, meet regulatory standards, and optimize your processes. Contact our experts today to find the right equipment for your laboratory's needs.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is a high-temperature muffle furnace necessary for POM desulfurization catalysts? Master Catalyst Activation

- Why must laboratory high-temperature sintering furnaces possess precise temperature control? Save Your Alumina Carriers

- What is a laboratory drying oven? The Essential Tool for Drying, Sterilizing, and Curing

- How is a high-temperature box resistance furnace utilized in the preparation of IrO2/Ti electrodes? Expert Guide

- What are batch furnaces best used for? Maximize Flexibility in Heat Treatment & R&D

- What role does a precision heat treatment furnace play in the T6 tempering process? Optimizing A356-SiCp Composites

- Why is a precision tempering furnace required for T24/T92 PWHT? Ensure Structural Integrity for Advanced Alloys

- What precautions should you take while using a muffle furnace? Ensure Safe High-Temperature Processing in Your Lab