Ball milling is a foundational top-down technique in nanotechnology, prized for its simplicity, scalability, and versatility. It excels at producing large quantities of nanopowders from bulk materials through a process of high-energy mechanical attrition. This makes it a highly efficient and cost-effective method for a wide range of applications, from materials science research to industrial production.

While often perceived as a simple grinding process, the true advantage of ball milling lies in its ability to not only reduce particle size but also to induce unique phase transformations and create novel materials, like amorphous alloys, that are difficult to synthesize through conventional chemical routes.

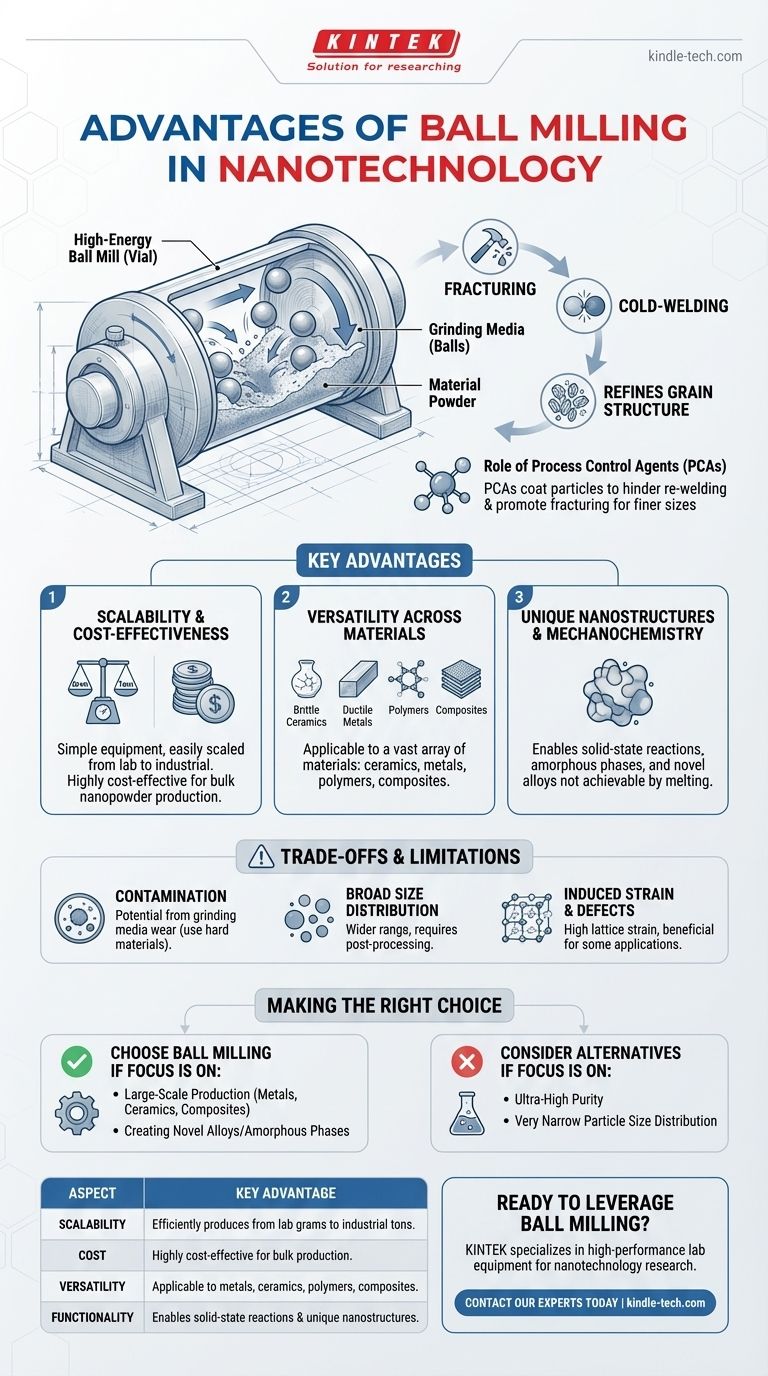

The Core Principle: How Ball Milling Creates Nanomaterials

Ball milling is a form of mechanical attrition. In a high-energy ball mill, a container (vial) is filled with the material to be milled (powder), the grinding media (balls), and often a process control agent. The vial is then subjected to high-energy agitation, causing the balls to repeatedly collide with the powder particles.

From Bulk to Nano: The Mechanism of Action

The process works through a balance of two competing mechanisms. High-kinetic energy impacts from the grinding balls cause the material's particles to fracture, breaking them down into smaller pieces.

Simultaneously, the immense pressure at the point of impact can cause these small particles to cold-weld together. This constant cycle of fracturing and welding ultimately refines the material's internal grain structure down to the nanoscale.

Not Just Grinding: Inducing Solid-State Reactions

High-energy ball milling is more than a size-reduction tool. The severe plastic deformation can drive solid-state reactions within the material.

This allows for the creation of nanocrystalline structures, amorphous (glassy) phases, and novel alloys from elemental powders, all accomplished at or near room temperature. This is a key advantage over traditional melting and casting methods.

The Role of Process Control Agents (PCAs)

To achieve nanoscale dimensions, it is crucial to prevent the fine particles from excessively cold-welding back into larger agglomerates.

Process Control Agents (PCAs), such as stearic acid or ethanol, are added in small amounts. These agents coat the surface of the powder particles, physically hindering re-welding and promoting the fracturing process, which helps achieve finer particle sizes and better uniformity.

Key Advantages in Nanotechnology Applications

The physical nature of ball milling gives it several distinct advantages over "bottom-up" chemical synthesis methods.

Scalability and Cost-Effectiveness

Ball milling equipment is relatively simple and can be easily scaled from grams in a laboratory setting to tons in an industrial one. This makes it one of the most cost-effective methods for producing bulk quantities of nanopowders, particularly for metals and ceramics.

Versatility Across Materials

The technique is exceptionally versatile. It can be applied to a vast array of material systems, including brittle ceramics, ductile metals, polymers, and composites. This flexibility allows researchers and engineers to use a single method to explore many different types of nanomaterials.

Formation of Unique Nanostructures

As mentioned, ball milling is a powerful tool for mechanochemistry. It enables the synthesis of materials that are thermodynamically unstable or difficult to form through other means, such as supersaturated solid solutions and non-equilibrium alloy phases.

Understanding the Trade-offs and Limitations

No technique is perfect. To use ball milling effectively, you must be aware of its inherent limitations.

Contamination Concerns

A significant drawback is the potential for contamination. The constant, high-energy impact can cause minute amounts of the grinding balls and the vial wall to wear away and mix with the powder. Choosing appropriate, hard-wearing materials (like tungsten carbide or zirconia) is critical to minimize this effect.

Broad Particle Size Distribution

Compared to precise chemical synthesis methods, ball milling often produces a wider distribution of particle sizes. Achieving a very narrow, uniform size typically requires additional post-processing steps like sieving or classification.

Induced Strain and Defects

The process inherently introduces a high degree of lattice strain and crystal defects into the final material. While this can be beneficial for certain applications (e.g., enhancing catalytic activity), it can be detrimental for others that require a perfect crystal structure.

Making the Right Choice for Your Goal

Deciding whether to use ball milling depends entirely on your project's specific requirements for material type, quantity, purity, and structure.

- If your primary focus is large-scale production of metallic, ceramic, or composite nanopowders: Ball milling offers an unmatched combination of scalability and cost-effectiveness.

- If your primary focus is creating novel alloys or amorphous phases not achievable by melting: High-energy ball milling is a uniquely powerful solid-state processing tool for materials discovery.

- If your primary focus is achieving ultra-high purity or a very narrow particle size distribution: You should consider bottom-up chemical synthesis or vapor deposition methods as more suitable alternatives.

By understanding its principles and limitations, you can effectively leverage ball milling as a powerful and versatile tool in your materials science toolkit.

Summary Table:

| Aspect | Key Advantage |

|---|---|

| Scalability | Efficiently produces from lab-scale grams to industrial tons of nanopowders. |

| Cost | Highly cost-effective for bulk production compared to chemical methods. |

| Versatility | Applicable to a wide range of materials: metals, ceramics, polymers, composites. |

| Functionality | Enables solid-state reactions & creation of unique nanostructures (amorphous phases, alloys). |

Ready to leverage ball milling for your nanomaterial production?

KINTEK specializes in high-performance lab equipment, including ball mills and consumables, designed to meet the rigorous demands of nanotechnology research and development. Our solutions help you achieve efficient, scalable synthesis of nanopowders, from metals and ceramics to novel composites.

Contact our experts today to discuss your specific application and discover how our equipment can enhance your materials science workflow. Get in touch now!

Visual Guide

Related Products

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

People Also Ask

- What is the function of a planetary ball mill for c-LLZO precursors? Master Solid Electrolyte Prep

- How does a planetary mill work? Harnessing High-Energy Impact for Nano-Grinding

- What size are planetary mill particles? Achieve Nanoscale Precision for Your Materials

- What is the working principle of planetary ball mill? Unlock High-Energy Grinding for Nanoscale Results

- What is the difference between a ball mill and a planetary ball mill? Unlock the Right Grinding Technology for Your Lab