When considering industrial dewatering solutions, the belt filter press stands out for its unique combination of high throughput, continuous operation, and efficiency. It is a workhorse technology primarily used for separating solids from liquids in a slurry, particularly in municipal wastewater treatment plants and various industrial applications. Its advantages lie in its ability to process large volumes of sludge with relatively low energy consumption and operator oversight.

The core advantage of a belt filter press is its ability to provide continuous, high-volume dewatering at a low operational cost. However, its performance is critically dependent on the specific type of sludge and the effectiveness of the upstream chemical conditioning process.

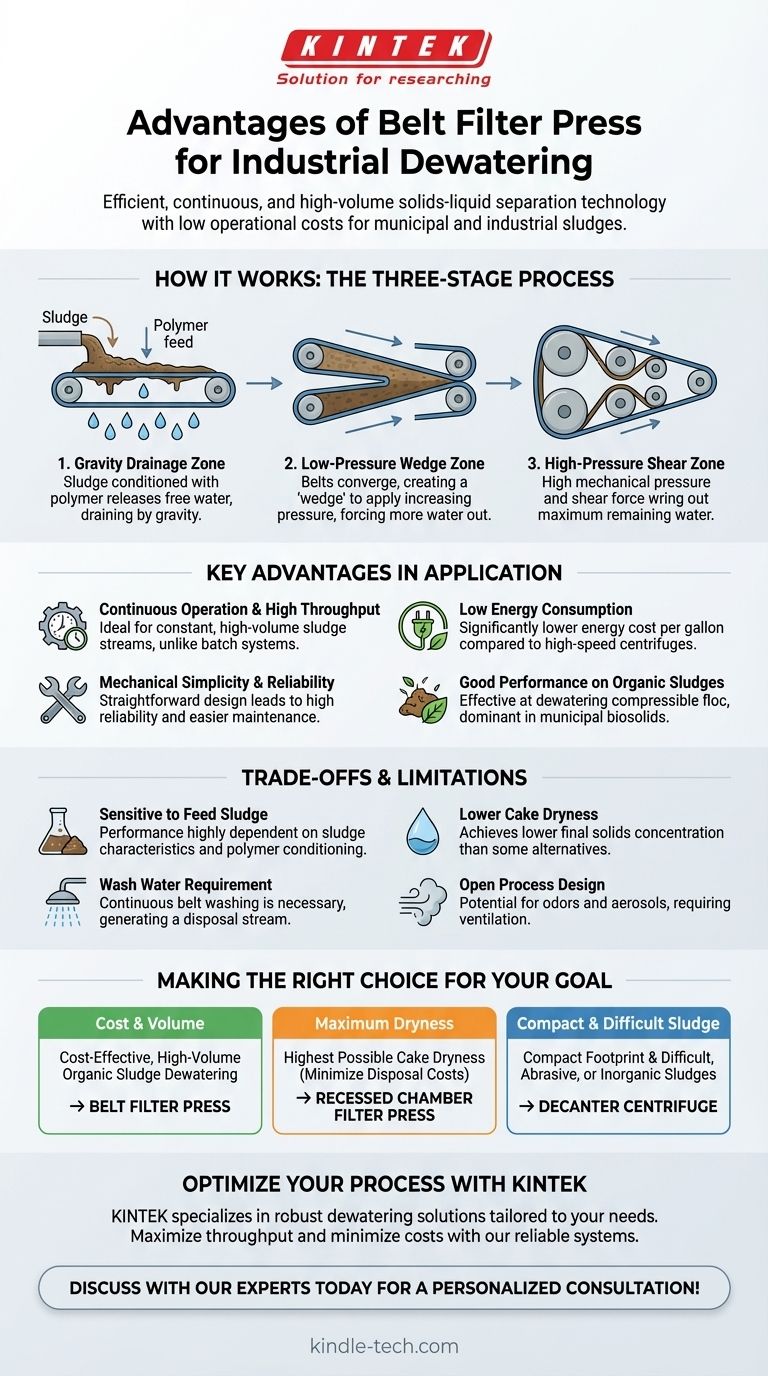

How a Belt Filter Press Works

To understand its advantages, it's essential to grasp its fundamental three-stage process. The machine uses two tensioned porous belts to continuously squeeze water from sludge.

The Initial Gravity Drainage Zone

Sludge, conditioned with a polymer, is first fed onto the top belt. The polymer helps clump solid particles together, releasing free water which drains by gravity through the porous belt.

The Low-Pressure Wedge Zone

As the sludge travels, the top and bottom belts converge. This creates a "wedge" that begins to apply gentle, increasing pressure, forcing more water out.

The High-Pressure Shear Zone

Finally, the sludge-filled belts travel around a series of rollers of decreasing diameter. This action applies high mechanical pressure and shear force, wringing out the maximum amount of remaining water.

Key Advantages in Application

The design of the belt filter press leads directly to its primary operational benefits.

Continuous Operation and High Throughput

Unlike batch systems like chamber filter presses, a belt press operates continuously. This makes it ideal for facilities that generate a constant, high-volume stream of sludge that requires dewatering.

Low Energy Consumption

The primary energy draw comes from the low-horsepower motors that drive the belts. Compared to high-speed centrifuges, which require significant energy to rotate a heavy bowl, the energy cost per gallon of processed sludge is substantially lower.

Mechanical Simplicity and Reliability

The design is straightforward and easy to understand. This mechanical simplicity often translates to high reliability, easier troubleshooting, and less specialized maintenance requirements compared to more complex equipment.

Good Performance on Organic Sludges

Belt presses are particularly effective at dewatering the fragile, compressible floc created from organic materials. This is why they are a dominant technology in municipal biosolids processing.

Understanding the Trade-offs and Limitations

No technology is perfect, and choosing a belt filter press requires understanding its potential downsides. Being aware of these limitations is crucial for successful implementation.

Sensitivity to Feed Sludge Consistency

The performance of a belt filter press is highly dependent on the characteristics of the incoming sludge and the effectiveness of polymer conditioning. Any upset in the upstream process can significantly impact dewatering results.

Lower Cake Dryness Than Alternatives

While effective, a belt press typically achieves a lower final "cake" solids concentration compared to a recessed chamber filter press or a high-solids centrifuge. If the goal is maximum water removal to minimize disposal costs, another technology might be superior.

Wash Water Requirement

The porous belts must be continuously sprayed with clean water to prevent blinding or clogging. This creates a wash water consumption and disposal stream that must be managed.

Open Process Design

Because the process is not fully enclosed, it can be a source of odors and aerosols. This may require additional ventilation or odor control measures, especially in sensitive locations.

Making the Right Choice for Your Goal

Selecting the correct dewatering technology depends entirely on your operational priorities.

- If your primary focus is cost-effective, continuous dewatering of high-volume organic sludge: A belt filter press is an excellent and often default choice due to its low energy use and proven reliability.

- If your primary focus is achieving the highest possible cake dryness to minimize hauling and disposal costs: You should evaluate a recessed chamber filter press, which can produce a drier product but operates in batches.

- If your primary focus is a compact footprint and handling difficult, abrasive, or inorganic sludges: A decanter centrifuge might be more suitable, despite its higher energy and maintenance costs.

Ultimately, a well-selected and properly operated belt filter press provides a robust, efficient, and reliable solution for large-scale dewatering challenges.

Summary Table:

| Advantage | Description |

|---|---|

| Continuous Operation | Processes sludge non-stop, ideal for high-volume streams. |

| High Throughput | Handles large volumes efficiently. |

| Low Energy Consumption | Lower operational cost compared to alternatives like centrifuges. |

| Mechanical Simplicity | Easy to maintain and troubleshoot. |

| Effective on Organic Sludges | Excellent for municipal biosolids processing. |

Optimize your sludge dewatering process with the right equipment.

At KINTEK, we specialize in providing robust and efficient laboratory and industrial equipment, including dewatering solutions tailored to your specific needs. Whether you're processing municipal biosolids or industrial slurry, our expertise ensures you get a reliable system that maximizes throughput and minimizes operational costs.

Let's discuss how a belt filter press can enhance your operation. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Warm Isostatic Press for Solid State Battery Research

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What is the function of a bench-top laboratory hydraulic press for XRF? Maximize Accuracy in Prosopis juliflora Analysis

- What is an example of a hydraulic press? Discover the Power of Laboratory Sample Preparation

- How does a laboratory hydraulic press contribute to the preparation of green pellets for nanostructured eutectic steel?

- Why is a laboratory hydraulic press required during the preparation of Ti3AlC2 precursor pellets?

- What role does a laboratory hydraulic press play in all-solid-state battery fabrication? Enhancing Ion Conductivity