The primary advantage of ceramic sintering is its ability to transform a compacted powder, known as a "green body," into a dense, solid, and mechanically strong object. This high-temperature process fundamentally reduces internal porosity, causing the individual ceramic particles to fuse together. The result is a finished part with vastly improved strength, conductivity, and other engineered properties that were absent in its powdered form.

Sintering is not merely a hardening process; it is a method of microstructural engineering. Its true advantage lies in the precise control it offers over a material's final density, which in turn dictates its mechanical, thermal, and electrical performance, all while enabling the mass production of complex shapes.

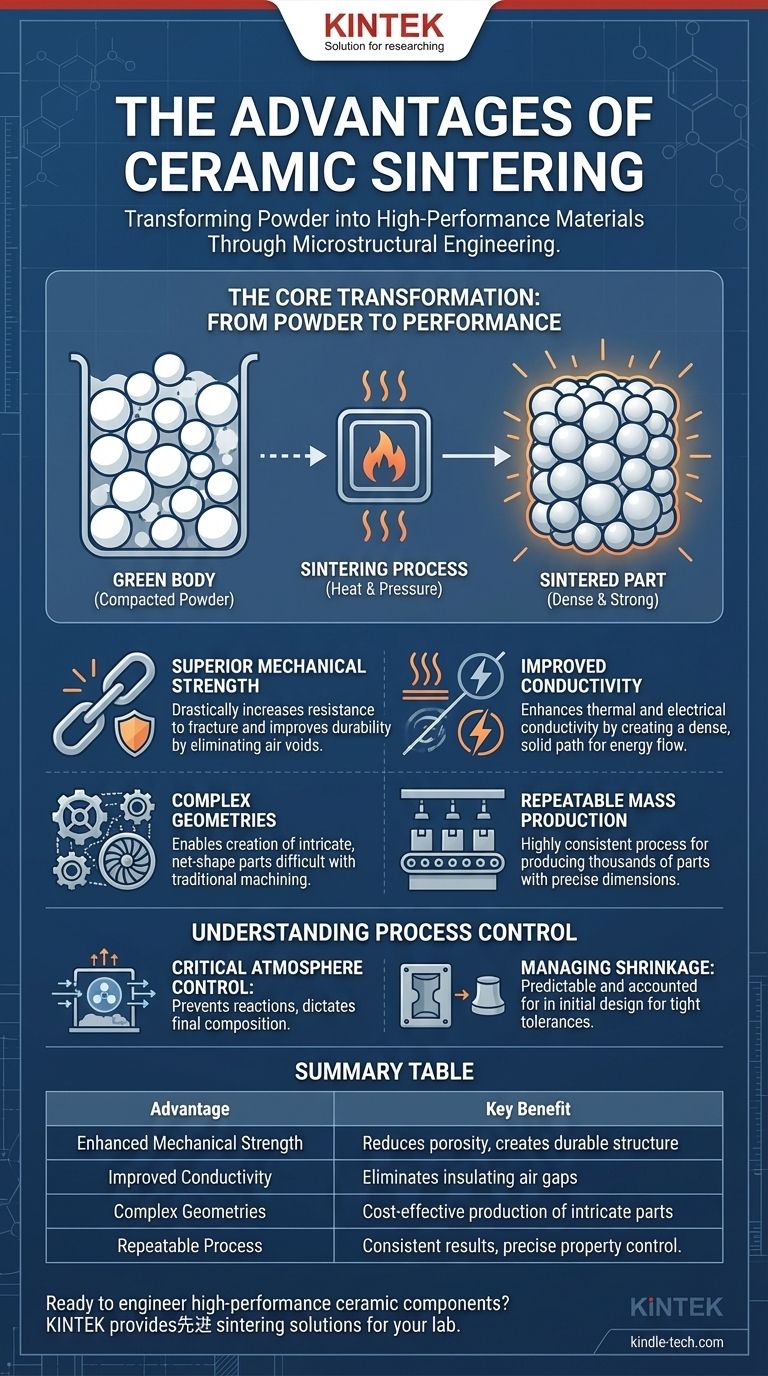

The Fundamental Goal: From Powder to Performance

Sintering is a thermal process that drives densification. At high temperatures, well below the material's melting point, atoms migrate between particles, fundamentally changing the material's structure from a loose collection of grains into a solid mass.

Reducing Porosity and Increasing Density

The initial "green body" is porous, with significant air gaps between the ceramic particles. During sintering, these voids shrink and are largely eliminated as the particles bond and pull closer together.

This reduction in porosity is directly linked to an increase in density. A denser part is inherently stronger and more robust.

Creating a Unified Polycrystalline Structure

Sintering encourages the formation of strong bonds, or "necks," between adjacent particles. Over time, these necks grow, and the individual grains coalesce into a unified, strong polycrystalline structure. This is the source of the sintered part's integrity and durability.

Enhancing Core Material Properties

By eliminating porosity and creating a dense, unified structure, sintering dramatically improves the inherent properties of the ceramic material.

Superior Mechanical Strength

Air voids are points of weakness. By removing them, sintering drastically increases the material's resistance to fracture and improves its overall strength and durability. The final object is far stronger than the initial compacted powder.

Improved Thermal and Electrical Conductivity

Pores filled with air are excellent insulators, hindering the flow of heat or electricity. By creating a dense, solid path, sintering allows energy to travel through the material more efficiently, significantly improving both thermal and electrical conductivity.

Enhanced Optical Translucency

In certain ceramics, porosity is what makes the material opaque, as the internal voids scatter light. Removing these pores through sintering can reduce light scattering, making the final ceramic object translucent or even transparent.

Key Manufacturing Advantages

Beyond improving material properties, sintering offers significant advantages as a manufacturing process, particularly for producing ceramic components at scale.

Repeatability for Mass Production

Sintering is an exceptionally reliable and repeatable process. Once the parameters are set, it can produce thousands or millions of parts with highly consistent dimensions and material properties, making it ideal for mass production.

Freedom to Create Complex Geometries

Many advanced ceramic parts have intricate shapes that are difficult or impossible to create with traditional machining. Sintering allows for the creation of these complex, "net-shape" geometries by first forming the powder in a mold and then solidifying it.

Cost-Effectiveness at Scale

While the initial setup for sintering can be capital-intensive, the process is extremely cost-effective for large production volumes. It minimizes material waste and can produce finished parts that require little to no subsequent processing.

Understanding the Trade-offs and Process Control

Effective sintering requires a deep understanding of the process variables. These factors are not limitations but rather levers for controlling the final outcome.

The Critical Role of Atmosphere

Sintering in a controlled atmosphere (e.g., vacuum or a specific gas) prevents unwanted chemical reactions and allows for precise control over the material's final composition. For ceramics sensitive to oxidation, this is not just an advantage but a necessity.

Managing Shrinkage

Densification inherently causes the part to shrink. This shrinkage is predictable and must be accurately accounted for during the initial mold design to ensure the final part meets its required dimensional tolerances.

Balancing Porosity and Strength

While the goal is often full densification, sometimes a specific level of porosity is desired. For applications like filters or catalysts, sintering can be controlled to increase strength while intentionally preserving a network of pores.

Applying Sintering to Your Goal

Your specific objective will determine how you leverage the sintering process.

- If your primary focus is achieving maximum material performance: Aim for complete densification to maximize strength, conductivity, and (if applicable) translucency.

- If your primary focus is cost-effective mass production: Leverage sintering's ability to create complex, net-shape parts with extreme accuracy and repeatability across high volumes.

- If your primary focus is creating a specialized functional material: Use precise control over temperature and atmosphere to engineer specific properties, such as the controlled porosity needed for filters and catalysts.

Ultimately, mastering the sintering process provides you with the power to engineer a ceramic material's microstructure to achieve your exact performance goals.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Enhanced Mechanical Strength | Reduces porosity, creating a dense, durable polycrystalline structure. |

| Improved Conductivity | Increases thermal and electrical conductivity by eliminating insulating air gaps. |

| Complex Geometries | Enables cost-effective mass production of intricate, net-shape parts. |

| Repeatable Process | Provides consistent results and precise control over final material properties. |

Ready to engineer high-performance ceramic components for your laboratory?

The ceramic sintering process is key to creating parts with superior strength, thermal stability, and precise geometries. At KINTEK, we specialize in providing the advanced lab equipment and consumables necessary to master this critical thermal process.

Whether you are scaling up production or developing new materials, our expertise can help you achieve the exact density and performance your application requires.

Contact KINTEK today to discuss how our sintering solutions can enhance your research and production capabilities.

Visual Guide

Related Products

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Why are quartz tubes preferred for chromium powder combustion? Superior Heat Resistance & Optical Clarity

- What are the primary functions of high-precision tube furnaces in graphene growth? Achieve Defect-Free GS Synthesis

- What is the function of quartz tubes and vacuum sealing systems? Secure Your High-Purity Solid Solution Synthesis

- Why use quartz tubes and vacuum sealing for sulfide solid-state electrolytes? Ensure Purity & Stoichiometry

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan