The primary advantages of a coreless induction furnace are its exceptional metallurgical control, high operational efficiency, and significant environmental benefits. This technology uses a water-cooled copper coil to generate a strong magnetic field, which directly and rapidly heats the metal charge without any physical contact or combustion, resulting in a cleaner and more precise melting process.

A coreless induction furnace's key advantage stems from its design: by eliminating the iron core, it enables direct, rapid, and clean heating of the metal. This provides unmatched control over the final product's temperature and chemical composition, making it a superior choice for producing high-purity and specialized alloys.

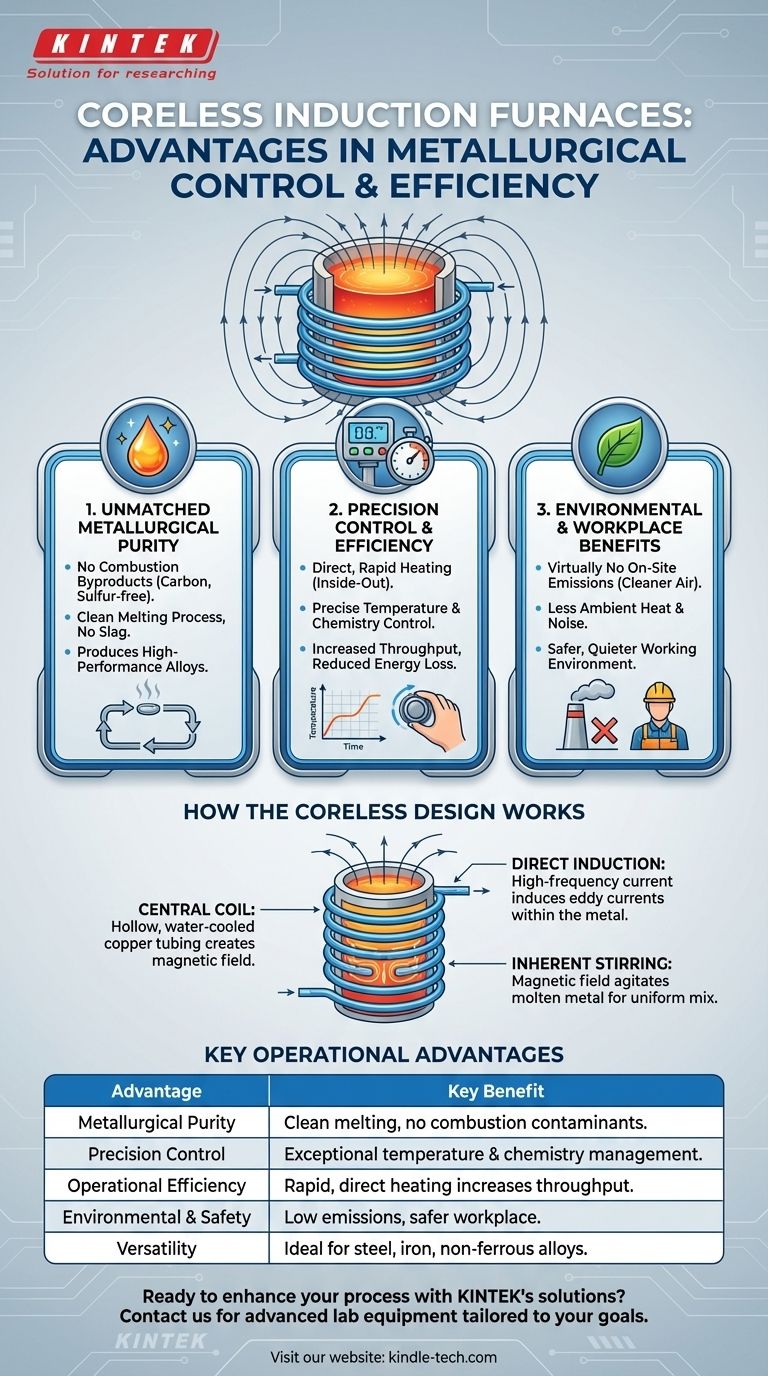

How the Coreless Design Drives Its Advantages

A coreless induction furnace's performance is a direct result of its fundamental components and the principle of induction heating. Understanding this foundation clarifies why its benefits are so significant.

The Central Coil Design

The heart of the furnace is a helical coil made from high-conductivity, hollow copper tubing. This coil is housed within a steel shell, often with magnetic shielding to prevent the shell from heating up.

A cooling system, typically circulating water, runs through the hollow coil. This is critical to dissipate the immense heat generated and protect the coil from melting.

The Principle of Direct Induction

When a high-frequency alternating current is passed through the coil, it creates a powerful and fluctuating magnetic field. This field passes through the refractory crucible and induces strong electrical currents (eddy currents) directly within the metal charge itself.

The metal's natural electrical resistance causes these currents to generate intense heat, melting the material from the inside out. This process is incredibly efficient as the heat is generated precisely where it's needed—in the metal—not in a surrounding chamber.

Inherent Stirring Action

The magnetic fields also create a natural stirring or agitating effect within the molten metal. This ensures an even distribution of heat and allows for uniform mixing of alloying elements, resulting in a homogenous and consistent final product.

Key Operational Advantages Explained

The unique operating principle of a coreless induction furnace translates into several distinct operational benefits that are difficult to achieve with traditional fuel-fired furnaces.

Unmatched Metallurgical Purity

Because there is no fuel combustion, there are no byproducts like carbon, sulfur, or other gases to contaminate the melt. This lack of slag and air pollution ensures the production of very clean, high-performance alloys.

Precision Temperature and Chemistry Control

The power supplied to the coil can be controlled with extreme precision. This gives operators a high degree of control over the metal's temperature, allowing for consistent quality and the ability to meet strict metallurgical specifications.

Rapid Melting and High Efficiency

Heating is direct, concentrated, and incredibly fast. This rapid melting speed increases throughput and reduces energy loss compared to methods that must first heat a large chamber before the heat can transfer to the metal.

Versatility Across Applications

Coreless induction furnaces are highly flexible. They are ideal for melting a wide range of materials, including various grades of steel, iron, and many non-ferrous alloys. They are also highly effective for re-melting scrap and recycled materials.

Understanding the Trade-offs

While powerful, this technology is not without its specific requirements and considerations. Objectivity demands acknowledging these factors.

Sophisticated Power Supply Requirements

The furnace requires a complex power supply unit consisting of transformers, inverters, and capacitor banks to convert line-frequency power to the high-frequency current needed for induction. This represents a significant initial capital investment.

Critical Cooling Systems

The water-cooling system for the coil and power supply is non-negotiable. It adds complexity to the installation and maintenance, and any failure in the cooling system can lead to catastrophic damage to the coil.

Refractory Lining Management

The crucible, or refractory lining, that holds the molten metal is a consumable component. It is subject to extreme thermal and chemical stress and requires regular inspection, maintenance, and eventual replacement, which constitutes an ongoing operational cost.

Environmental and Workplace Benefits

Beyond operational performance, the coreless induction furnace offers compelling advantages for sustainability and worker safety.

Reduced On-Site Emissions

The melting process is virtually free of the smoke, dust, and flames associated with combustion. This eliminates the on-site emission of pollutants like CO2 and SOx, resulting in cleaner air and easier environmental compliance.

Improved Working Environment

Compared to traditional furnaces, induction furnaces produce significantly less ambient heat and noise. This creates a safer, cleaner, and more comfortable environment for operators and surrounding personnel.

Making the Right Choice for Your Goal

Selecting a coreless induction furnace depends on balancing its high performance and upfront cost against your specific production priorities.

- If your primary focus is alloy quality and purity: The furnace's clean melting process provides superior metallurgical control, free from the contaminants of fuel-fired systems.

- If your primary focus is operational speed and flexibility: Its rapid melting cycles and suitability for diverse metals make it ideal for agile and high-throughput production environments.

- If your primary focus is environmental compliance and worker safety: The technology's low emissions and quieter, cleaner operation offer clear advantages over traditional combustion-based furnaces.

Ultimately, the coreless induction furnace is a powerful tool for any operation that requires precise, clean, and efficient melting of metals.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Metallurgical Purity | Clean melting process, free from combustion contaminants like carbon or sulfur. |

| Precision Control | Exceptional control over temperature and chemical composition for consistent quality. |

| Operational Efficiency | Rapid, direct heating from the inside out increases throughput and reduces energy loss. |

| Environmental & Safety | Virtually no on-site emissions, less ambient heat, and a quieter, safer workplace. |

| Versatility | Ideal for melting a wide range of metals, including steel, iron, and non-ferrous alloys. |

Ready to enhance your metal melting process with precision and efficiency?

A coreless induction furnace from KINTEK delivers the superior metallurgical control and clean operation you need for producing high-purity alloys. Our expertise in advanced lab equipment ensures you get a solution tailored to your specific production goals—whether it's maximizing purity, increasing throughput, or meeting strict environmental standards.

Contact us today using the form below to discuss how our induction furnaces can benefit your laboratory or production facility. Let's achieve your goals together.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is the primary function of a vacuum induction melting furnace? Melt High-Purity Metals with Precision

- What is the principle of vacuum induction melting? Achieve Ultra-High Purity Metals

- How does induction work in a vacuum? Achieve Ultra-Pure Metal Melting with VIM

- What is the difference between induction melting and vacuum induction melting? Choosing the Right Process for Purity

- What are the advantages of induction melting? Achieve Faster, Cleaner, and More Controlled Metal Melting