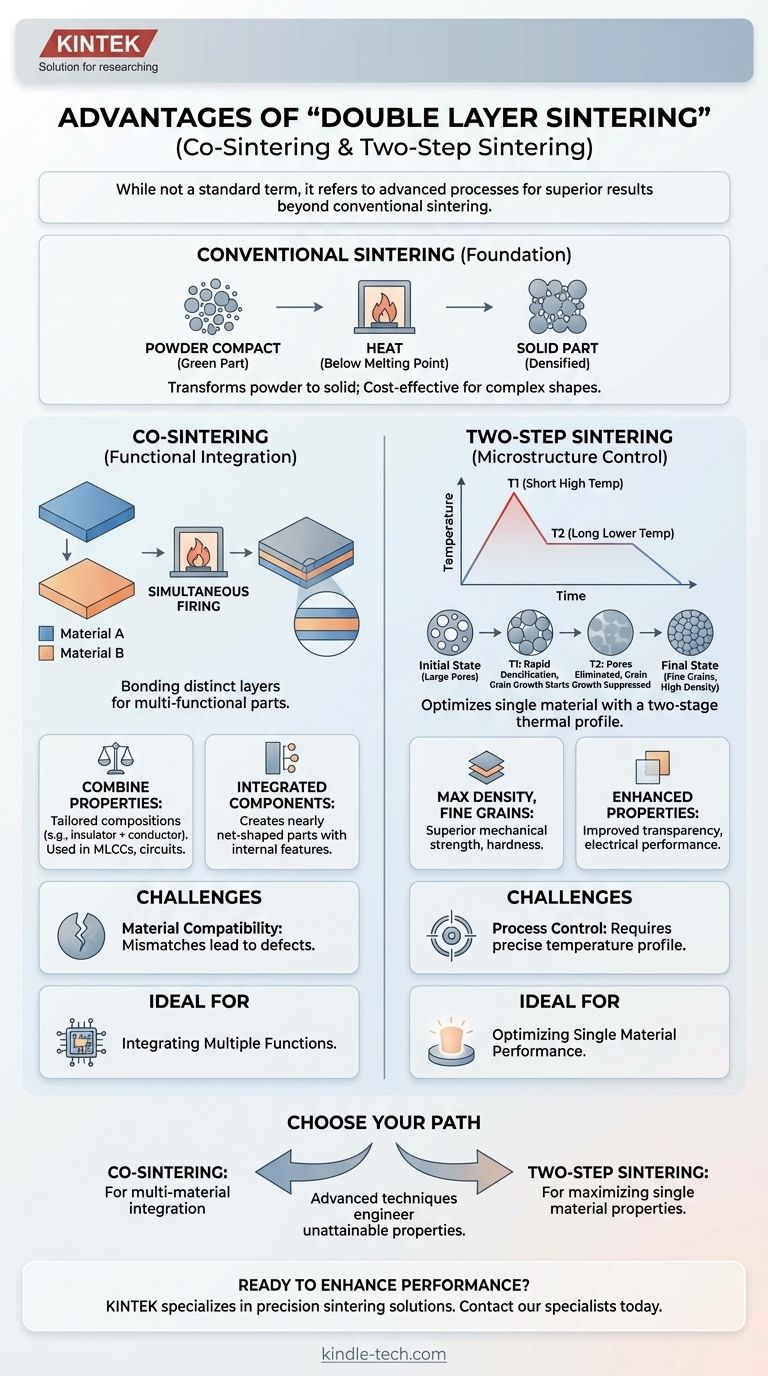

While the term "double layer sintering" is not standard, it most often refers to one of two advanced manufacturing processes: co-sintering or two-step sintering. Co-sintering involves bonding two distinct material layers together to create a functionally integrated component, while two-step sintering uses a specific temperature profile to achieve superior density and microstructure in a single material. The primary advantage of these techniques is the ability to either combine disparate material properties or to enhance the performance of a single material beyond what conventional sintering can achieve.

These advanced sintering methods move beyond creating simple, monolithic parts. Their core advantage is enabling either the integration of multiple functions into a single component or the creation of exceptionally dense, fine-grained materials with superior mechanical and physical properties.

Sintering Fundamentals: From Powder to Part

Before exploring layered techniques, it's essential to understand conventional sintering. This is a thermal process that transforms a compacted powder into a solid, coherent mass without melting it.

The Sintering Mechanism

Sintering works by heating a "green part" (compacted powder) to a high temperature below its melting point. This heat activates diffusion, causing the powder particles to bond together at their contact points.

These "sintered necks" grow over time, gradually reducing the empty space, or porosity, between particles. This process densifies the material, significantly improving its properties.

General Benefits of Sintering

The process is valued across industries for several key reasons. It enables the cost-effective mass production of components with complex, non-machinable geometries.

Sintering also allows for the creation of parts from materials with extremely high melting points and offers precise control over the final material's purity, uniformity, and strength.

Interpretation 1: Co-Sintering for Functional Integration

The most common interpretation of "double layer sintering" is co-sintering, where two or more different layers of material are sintered simultaneously to form a single, laminated component.

What is Co-Sintering?

This technique involves stacking layers of different green-state materials—for example, a ceramic insulator and a metallic conductor—and firing them together. The goal is to create a multi-functional device in a single, efficient process step.

Key Advantage: Combining Material Properties

Co-sintering’s primary benefit is its ability to create a part with tailored material compositions. You can design a component that is both structurally supportive and electrically conductive, or one that has both a magnetic layer and a non-magnetic substrate.

This is fundamental to modern electronics, such as in the manufacturing of Multi-Layer Ceramic Capacitors (MLCCs) and complex circuit packages.

Key Advantage: Creating Integrated, Net-Shaped Components

By building a component layer by layer before firing, co-sintering can produce intricate, nearly net-shaped objects with internal features. This is invaluable for creating integrated devices with embedded channels or conductive pathways that would be impossible to manufacture otherwise.

Interpretation 2: Two-Step Sintering for Microstructure Control

A second, more technical interpretation is two-step sintering. This is not about multiple material layers but a two-stage temperature profile used to optimize the final properties of a single material.

What is Two-Step Sintering?

In this process, the part is first heated to a high temperature for a very short time. It is then quickly cooled to a slightly lower temperature and held there for an extended period.

Key Advantage: Maximizing Density while Suppressing Grain Growth

The main advantage is achieving near-full density while keeping the material's grain size extremely small. Conventional sintering often causes grains to grow large as the part densifies, which can compromise mechanical strength.

Two-step sintering separates the densification process from the grain growth process. The lower-temperature hold allows pores to be eliminated without giving the grains time and energy to coarsen, resulting in a fine-grained, high-density microstructure.

Key Advantage: Enhanced Mechanical and Functional Properties

A fine-grained microstructure directly translates to superior material performance. This includes significantly improved strength, hardness, and durability.

For certain materials, such as transparent ceramics, minimizing grain size and eliminating porosity is critical for achieving high transparency and other desirable optical or electrical properties.

Understanding the Trade-offs

While powerful, these advanced techniques introduce complexities that are not present in conventional sintering.

The Challenge of Co-Sintering: Material Compatibility

Successfully co-firing different materials requires them to be highly compatible. Mismatches in shrinkage rates, thermal expansion coefficients, or chemical reactivity can lead to warping, cracking (delamination), or other defects, rendering the part useless.

The Challenge of Two-Step Sintering: Process Control

This method demands extremely precise control over the furnace's temperature profile. If the initial high temperature is held for too long, or if the lower holding temperature is incorrect, you can fail to achieve full density or still end up with unwanted grain growth.

How to Apply This to Your Project

Your choice depends entirely on your end goal, as these techniques solve different problems.

- If your primary focus is integrating multiple functions (e.g., electronic circuits, sensors): Co-sintering is the correct approach to create a laminated, multi-material component.

- If your primary focus is maximizing the performance of a single material (e.g., strength, transparency): Two-step sintering is the superior method for achieving an optimal microstructure.

- If your primary focus is the cost-effective production of a standard part: Conventional single-step sintering remains the most straightforward and reliable method.

Ultimately, these advanced sintering techniques empower you to engineer materials and components with properties and functions that are simply unattainable through conventional methods.

Summary Table:

| Technique | Primary Goal | Key Advantage | Ideal For |

|---|---|---|---|

| Co-Sintering | Bond different material layers | Functional integration of disparate properties | Multi-layer ceramics, integrated circuits, sensors |

| Two-Step Sintering | Optimize single material properties | Maximum density with minimal grain growth | High-strength ceramics, transparent materials, fine-grained components |

Ready to enhance your material performance with advanced sintering solutions? KINTEK specializes in precision lab equipment and consumables for sintering applications. Whether you're developing multi-functional components with co-sintering or optimizing material properties with two-step sintering, our expertise and products can help you achieve superior results. Contact our sintering specialists today to discuss your specific laboratory needs and discover how KINTEK can support your research and production goals.

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat Sintering Brazing Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

People Also Ask

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What are the factors influencing shrinkage during sintering? Control Dimensional Changes for Precision Parts

- Why is a high vacuum required for sintering Ti-43Al-4Nb-1Mo-0.1B? Ensure Purity & Fracture Toughness

- Why is a high vacuum environment necessary in sintering equipment for TiAl alloys? Ensure High-Purity Metal Bonding

- Does sintering use diffusion? The Atomic Mechanism for Building Stronger Materials