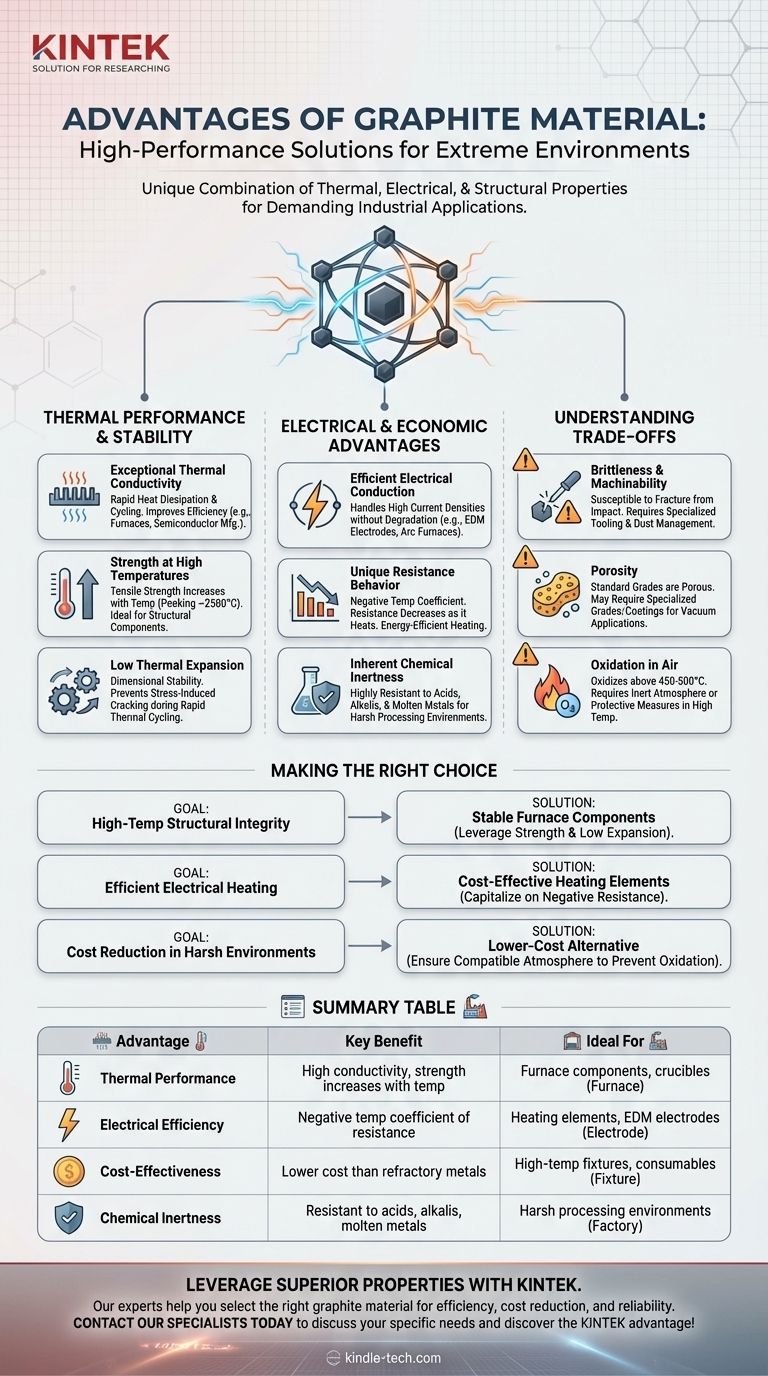

The primary advantages of graphite stem from its unique combination of thermal, electrical, and structural properties. It excels at conducting heat and electricity, maintains its strength at extreme temperatures, and is significantly more cost-effective than many specialized metals, making it a cornerstone material for demanding industrial applications.

While often chosen for its low cost, graphite's true value lies in its predictable and superior performance in high-temperature environments where most conventional materials would fail or become prohibitively expensive.

Thermal Performance and Stability

Graphite's behavior under thermal stress is arguably its most valuable characteristic. Unlike metals that weaken as they heat up, graphite follows a different set of rules.

Exceptional Thermal Conductivity

Graphite has excellent thermal conductivity, allowing it to dissipate heat quickly and evenly. This property also allows for rapid heating and cooling cycles.

This reduces the overall process time in applications like industrial furnaces or semiconductor manufacturing, directly improving operational efficiency and throughput.

Strength at High Temperatures

A key differentiator for graphite is that its tensile strength can actually increase with temperature, peaking at around 2500°C.

This is the opposite of metals and ceramics, making graphite an ideal structural material for high-temperature furnace components, fixtures, and crucibles.

Low Thermal Expansion

The material has a very low coefficient of thermal expansion, meaning it does not significantly change its size or shape when subjected to extreme temperature changes.

This dimensional stability prevents stress-induced cracking and failure, ensuring reliability in components that undergo rapid thermal cycling.

Electrical and Economic Advantages

Beyond its thermal resilience, graphite offers distinct electrical and cost benefits, particularly when compared to refractory metals like tungsten or molybdenum.

Efficient Electrical Conduction

Graphite is an excellent electrical conductor, a property that makes it suitable for electrodes, current collectors, and heating elements.

Its ability to handle high current densities without degrading is crucial for applications like Electric Discharge Machining (EDM) and arc furnaces.

Unique Resistance Behavior

Unlike conventional metallic conductors, graphite exhibits a negative temperature coefficient of resistance. As it heats up, its electrical resistance decreases.

This makes it an exceptionally energy-efficient material for heating elements, as it becomes a better conductor precisely when it is needed most. This efficiency, combined with its low material cost, provides a powerful economic advantage.

Inherent Chemical Inertness

Graphite is highly resistant to chemical attack and corrosion from most acids, alkalis, and solvents.

This inertness allows it to be used in harsh chemical processing environments and for handling molten metals, where material purity is paramount.

Understanding the Trade-offs

No material is perfect. Acknowledging graphite's limitations is essential for successful implementation and avoiding costly failures.

Brittleness and Machinability

Graphite is a brittle material and lacks the ductility of metals. It is susceptible to fracture from sharp impacts or high tensile stress at room temperature.

While it can be machined into complex shapes, it requires specialized tooling and expertise to prevent chipping and breakout. The resulting dust is also electrically conductive and must be carefully managed.

Porosity

Standard grades of graphite are porous. This can be a significant drawback in vacuum furnace applications or when handling gases, as it can lead to outgassing or leaks.

Specialized, higher-density grades or impervious coatings are required to overcome this limitation, which can increase the overall cost.

Oxidation in Air

While graphite performs exceptionally well in vacuum or inert atmospheres, it will begin to oxidize (burn) in the presence of oxygen at temperatures above 450-500°C.

This is a critical operating constraint. Any high-temperature application using graphite in an oxygen-rich environment must incorporate protective measures or accept a limited component lifespan.

Making the Right Choice for Your Application

Selecting graphite requires matching its specific properties to your primary engineering goal.

- If your primary focus is high-temperature structural integrity: Leverage graphite's unique ability to get stronger as it heats up, combined with its low thermal expansion, for stable furnace components.

- If your primary focus is efficient electrical heating: Capitalize on its negative temperature coefficient of resistance for creating cost-effective and energy-efficient heating elements.

- If your primary focus is cost reduction in harsh environments: Use graphite as a lower-cost alternative to refractory metals, but ensure the operating atmosphere is compatible (e.g., vacuum or inert gas) to prevent oxidation.

By understanding these fundamental properties and trade-offs, you can leverage graphite not just as a material, but as a strategic solution for extreme engineering challenges.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Thermal Performance | High conductivity, strength increases with temperature | Furnace components, crucibles |

| Electrical Efficiency | Negative temperature coefficient of resistance | Heating elements, EDM electrodes |

| Cost-Effectiveness | Lower cost than refractory metals | High-temperature fixtures, consumables |

| Chemical Inertness | Resistant to acids, alkalis, molten metals | Harsh processing environments |

Ready to leverage graphite's superior properties in your lab or process?

At KINTEK, we specialize in high-performance lab equipment and consumables, including precision graphite components for demanding applications. Our experts can help you select the right graphite material to enhance your efficiency, reduce costs, and ensure reliability in extreme conditions.

Contact our specialists today to discuss your specific needs and discover the KINTEK advantage!

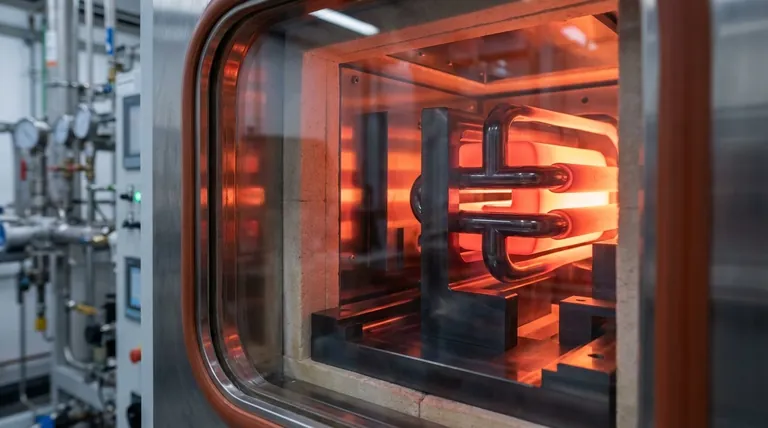

Visual Guide

Related Products

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

People Also Ask

- What are the available specifications for the gold and platinum sheets? High-Purity Sheets for Demanding Applications

- What is the function of the platinum electrode in SHE? It's the Inert Catalyst for a Universal Standard

- What is the function of the SCE in testing FeCrNiCoNb0.5 alloys? Achieve Precise Electrochemical Measurements

- How should a platinum disk electrode be used during an experiment? A Guide to Accurate Electrochemical Measurements

- What are the properties and applications of a graphite disk electrode? Precision Tools for Electroanalysis

- What are the necessary pre-treatment steps for a platinum disk electrode before an experiment? Achieve Reliable Electrochemical Data

- What are the primary physicochemical reasons for selecting a carbon electrode as the anode in aluminum recovery? 5 Keys

- What is the material and purity of a gold disc electrode? Ensuring Precision in Electrochemical Analysis