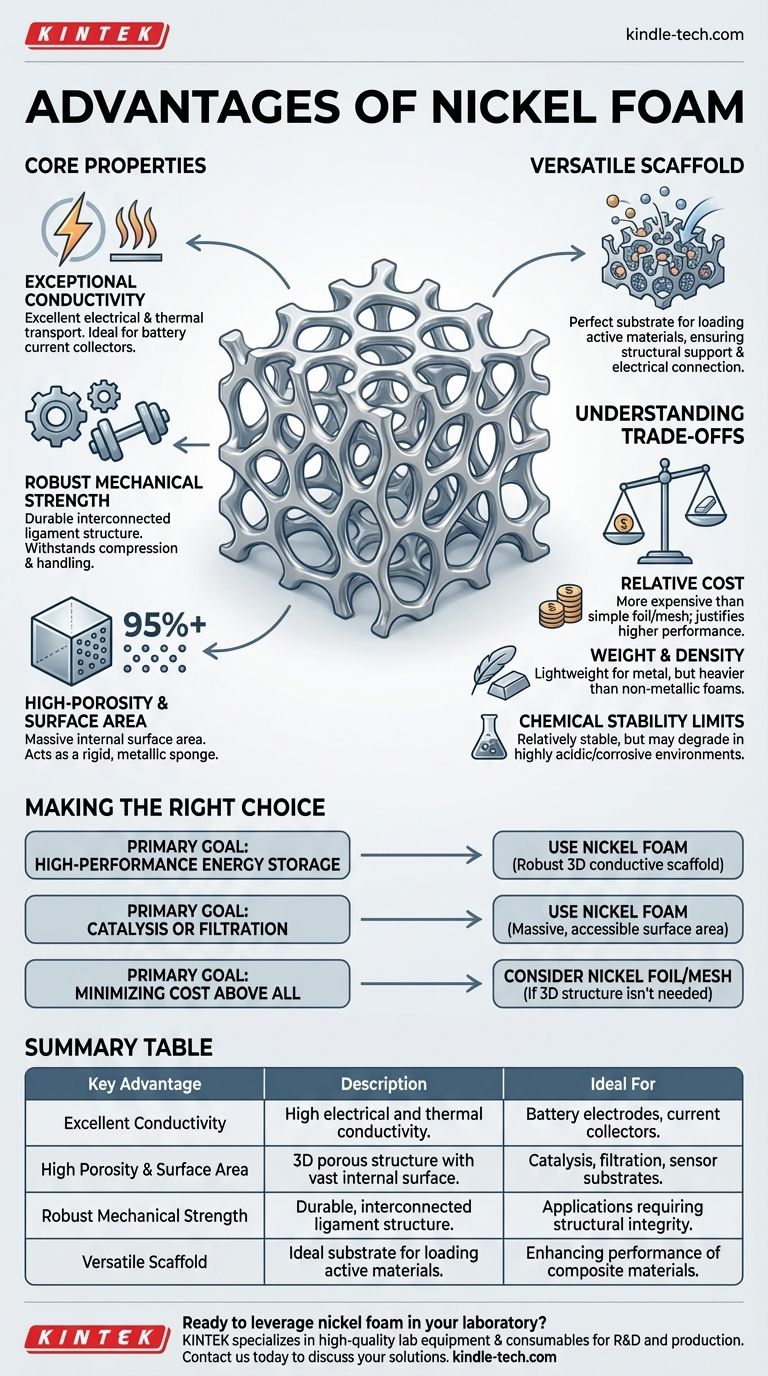

At its core, nickel foam is a highly versatile material valued for its unique combination of metallic properties and a three-dimensional porous structure. Its primary advantages are excellent electrical conductivity, robust mechanical strength, and a vast surface area that makes it an ideal scaffold for other materials, all while remaining relatively cost-effective.

The true advantage of nickel foam is not a single feature, but the synergy of its properties. It acts as a lightweight, strong, and highly conductive metal sponge, making it a superior framework for advanced applications like high-performance batteries and catalysts.

The Core Properties of Nickel Foam

To understand why nickel foam is chosen for demanding applications, we must first break down its fundamental characteristics.

Exceptional Electrical and Thermal Conductivity

As a metallic material, nickel foam is an excellent conductor of electricity and heat. This is a non-negotiable requirement for applications like battery current collectors, where efficient electron transport is critical to performance.

Robust Mechanical Strength

Unlike brittle powders or thin foils, nickel foam possesses significant mechanical strength and structural integrity. Its interconnected ligament structure can withstand compression, vibration, and handling, ensuring durability in the final device.

The High-Porosity, 3D Structure

The most defining feature of nickel foam is its extremely high porosity, often exceeding 95%. This creates an open-cell, three-dimensional network with an immense internal surface area. Think of it as a rigid, metallic sponge.

Versatile Surface for Active Materials

This vast surface area makes nickel foam a perfect substrate or scaffold. It provides an ideal foundation for loading "active materials," such as the catalysts used in chemical reactors or the electrode materials in batteries, ensuring they are both structurally supported and electrically connected.

Understanding the Trade-offs

No material is perfect. Acknowledging the trade-offs of nickel foam is critical for making an informed engineering decision.

Cost-Effectiveness is Relative

While the reference notes its cost-effectiveness, this is contextual. Nickel foam is more expensive than simple nickel foil or mesh. Its value comes from the performance it enables, which often justifies the higher initial cost compared to less sophisticated alternatives.

Weight and Density

Though it is very lightweight for a metal structure, it is still a metal. In applications where every gram is critical and electrical conductivity is not the primary driver, polymer foams or other non-metallic porous materials may be a lighter alternative.

Chemical Stability Limits

Nickel is a relatively stable metal, but it is not completely inert. In highly acidic or corrosive environments, it can degrade. For such applications, more noble materials like platinum-coated foams or specialized alloys may be necessary, albeit at a significantly higher cost.

Making the Right Choice for Your Application

Your final decision depends entirely on your primary engineering goal. Use these guidelines to determine if nickel foam fits your needs.

- If your primary focus is high-performance energy storage: The 3D conductive scaffold is its key benefit for creating robust, high-capacity battery electrodes.

- If your primary focus is catalysis or filtration: The massive, accessible surface area is the most important advantage for maximizing reaction rates or capture efficiency.

- If your primary focus is minimizing cost above all else: A simpler nickel foil or mesh may be a more suitable choice if you do not need the 3D structure.

By understanding this unique combination of properties, you can effectively leverage nickel foam to solve complex engineering challenges.

Summary Table:

| Key Advantage | Description | Ideal For |

|---|---|---|

| Excellent Conductivity | High electrical and thermal conductivity. | Battery electrodes, current collectors. |

| High Porosity & Surface Area | 3D porous structure with vast internal surface. | Catalysis, filtration, sensor substrates. |

| Robust Mechanical Strength | Durable, interconnected ligament structure. | Applications requiring structural integrity. |

| Versatile Scaffold | Ideal substrate for loading active materials. | Enhancing performance of composite materials. |

Ready to leverage the unique properties of nickel foam in your laboratory?

KINTEK specializes in providing high-quality laboratory equipment and consumables. Whether you are developing next-generation batteries, advanced catalysts, or innovative filtration systems, our expertise and products are designed to support your R&D and production needs.

Contact us today to discuss how our solutions can help you achieve superior performance and efficiency in your projects.

Visual Guide

Related Products

- Copper Nickel Foam Metal Sheet

- Aluminum Foil Current Collector for Lithium Battery

- Copper Foam

- High Purity Zinc Foil for Battery Lab Applications

- Nickel Aluminum Tabs for Soft Pack Lithium Batteries

People Also Ask

- What are the characteristics of copper foam? Unlock High-Performance Thermal and Electrical Solutions

- What are the advantages disadvantages and uses of sheet metal? The Ultimate Guide to Material Selection

- What is the porosity of an RVC glassy carbon sheet? Understanding the Critical Difference Between PPI and Porosity

- What are the characteristics of nickel foam? A Guide to Its High-Performance Properties

- What electrostatic protection measures should be taken when using nickel and copper foam? Essential ESD Safety Protocols