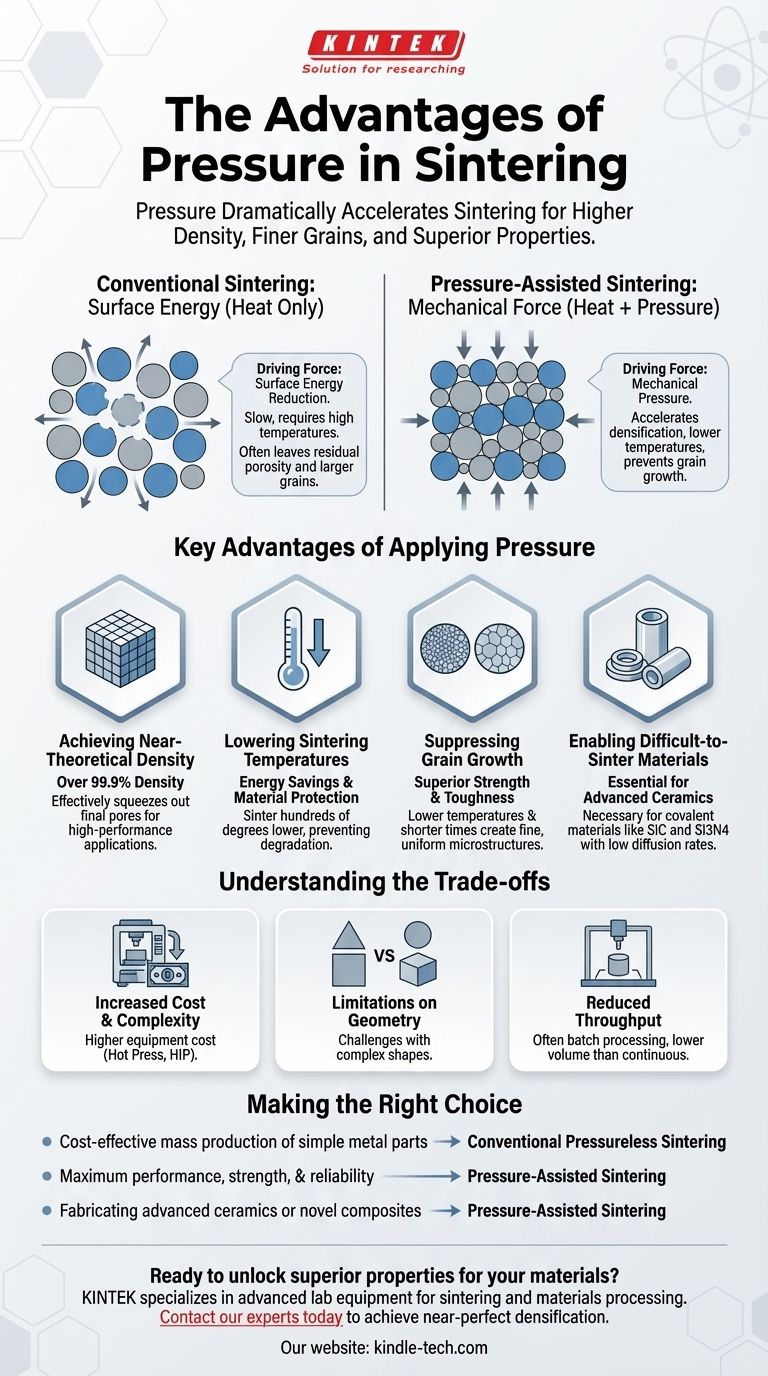

In short, applying external pressure during sintering dramatically accelerates the process, allowing for lower temperatures and shorter cycle times. This approach produces materials with significantly higher density, finer grain structures, and superior mechanical properties compared to conventional, pressureless sintering.

While conventional sintering relies solely on heat to slowly fuse particles, adding pressure introduces a powerful mechanical force. This force fundamentally changes the process, making it possible to achieve near-perfect densification while simultaneously preventing the unwanted grain growth that can weaken the final part.

The Fundamental Driving Forces of Sintering

Sintering is the process of compacting and forming a solid mass of material by heat and/or pressure without melting it to the point of liquefaction. Understanding the driving forces is key to understanding the role of pressure.

Conventional Sintering: A Surface Energy Game

In conventional, pressureless sintering, a powder compact is heated in a furnace. The primary driving force for densification is the reduction of surface energy.

Particles have a high surface area-to-volume ratio. The system seeks a lower energy state by reducing this surface area, which it accomplishes by forming "necks" between particles and gradually eliminating the pores between them.

This process relies entirely on atomic diffusion, which is often slow and requires very high temperatures maintained for long periods.

Pressure-Assisted Sintering: Adding a Mechanical Force

Applying external pressure introduces a powerful, additional driving force for densification. This is the core advantage.

This mechanical force physically pushes particles together, deforming them at their contact points. This dramatically enhances the rate of pore closure and material transport, overcoming the kinetic barriers that can slow down conventional sintering.

Key Advantages of Applying Pressure

By adding a mechanical driving force, pressure-assisted sintering unlocks several critical benefits that are often unattainable with heat alone.

Achieving Near-Theoretical Density

Conventional sintering often struggles to eliminate the last few percent of porosity, leaving residual pores that degrade material properties.

Pressure-assisted methods, such as Hot Isostatic Pressing (HIP), can effectively squeeze out these final voids. This allows for the fabrication of components with densities exceeding 99.9% of the theoretical maximum, which is essential for high-performance applications.

Lowering Sintering Temperatures

Because pressure provides a significant portion of the driving force for densification, less thermal energy is required.

This allows for sintering at temperatures hundreds of degrees lower than in pressureless processes. The result is significant energy savings and the ability to process materials that might decompose or undergo undesirable phase transformations at higher temperatures.

Suppressing Grain Growth

A material's mechanical strength is often inversely proportional to its grain size. Smaller grains mean a stronger, harder part.

The lower temperatures and shorter times used in pressure-assisted sintering directly inhibit grain growth. This allows for the production of parts with a fine, uniform microstructure, leading to superior strength, toughness, and fatigue resistance.

Enabling Difficult-to-Sinter Materials

Some materials, particularly those with strong covalent bonds like silicon carbide or silicon nitride, have extremely low rates of atomic diffusion.

These advanced ceramics are nearly impossible to sinter to full density using heat alone. The application of pressure is not just an advantage but a necessity to consolidate them effectively.

Understanding the Trade-offs

While the benefits are significant, pressure-assisted sintering is not the universal solution. It comes with practical trade-offs that must be considered.

Increased Equipment Cost and Complexity

The machinery required for pressure-assisted sintering, such as a hot press or a HIP unit, is far more complex and expensive than a conventional sintering furnace. This represents a significant capital investment.

Limitations on Geometry and Size

Applying uniform pressure to complex shapes can be challenging. While HIP is excellent for this, other methods like hot pressing are typically limited to simpler geometries. The size of the pressure vessel also places a hard limit on the maximum part size.

Reduced Throughput for Batch Processes

Many pressure-assisted techniques are batch processes, where one part or a small group of parts is processed at a time. This can have a lower throughput compared to the continuous belt furnaces often used in high-volume conventional sintering, impacting per-part cost.

Making the Right Choice for Your Goal

Selecting the correct sintering method depends entirely on the performance requirements and economic constraints of your application.

- If your primary focus is cost-effective mass production of simple metal parts: Conventional pressureless sintering is almost always the most economical and efficient choice.

- If your primary focus is maximum performance, strength, and reliability: Pressure-assisted sintering is critical for achieving the near-full density and fine microstructure required for aerospace, medical, or cutting tool applications.

- If your primary focus is fabricating advanced ceramics or novel composites: Applying pressure is often a fundamental requirement to achieve successful densification at all.

Ultimately, understanding when to apply pressure is the key to moving beyond simple consolidation and toward the intentional design of high-performance materials.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Higher Final Density | Achieves >99.9% theoretical density, eliminating pores that weaken parts. |

| Lower Sintering Temperature | Reduces energy costs and prevents material degradation. |

| Finer Grain Structure | Suppresses grain growth for superior strength, toughness, and fatigue resistance. |

| Enables Difficult Materials | Essential for sintering advanced ceramics like silicon carbide. |

Ready to unlock the superior properties of pressure-assisted sintering for your materials?

KINTEK specializes in advanced lab equipment for sintering and materials processing. Whether you are developing high-performance ceramics, advanced composites, or metal parts for demanding applications, our expertise and solutions can help you achieve the near-perfect densification and fine microstructures you need.

Contact our experts today to discuss how we can support your R&D and production goals with the right equipment and consumables.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the fundamentals of spark plasma sintering process? Unlock Rapid, High-Performance Material Consolidation

- How does the uniaxial pressure system of a vacuum hot press furnace contribute to the formation of graphite film/aluminum composite materials?

- What specific processing conditions does a vacuum hot pressing furnace provide for the sintering of FeCrAl composites?

- Why is the hot pressing process used for TlBr detectors? Engineering High-Performance Semiconductors

- What is the theory of spark plasma sintering? A Guide to Rapid, Low-Temperature Densification

- What are the core advantages of using a vacuum hot pressing furnace for Cr50Cu50 alloys? Achieve 96.09% Density

- What effect does a high-vacuum environment in a hot-press furnace have on Mo-Na alloys? Achieve Pure Microstructures

- Why is a vacuum hot pressing furnace required for Cu/rGO sintering? Achieve High Density and Conductivity