The primary advantages of pressure sintering are the ability to produce parts with superior material properties, create complex geometries that are difficult to machine, and achieve high production efficiency with minimal material waste. By applying external pressure during the heating process, it dramatically reduces porosity, which in turn increases the density, strength, and thermal and electrical conductivity of the final component.

The core benefit of adding pressure to the sintering process is achieving superior material density and strength at lower temperatures and in less time than conventional, pressureless methods. This unlocks a higher level of performance for a wide range of advanced materials.

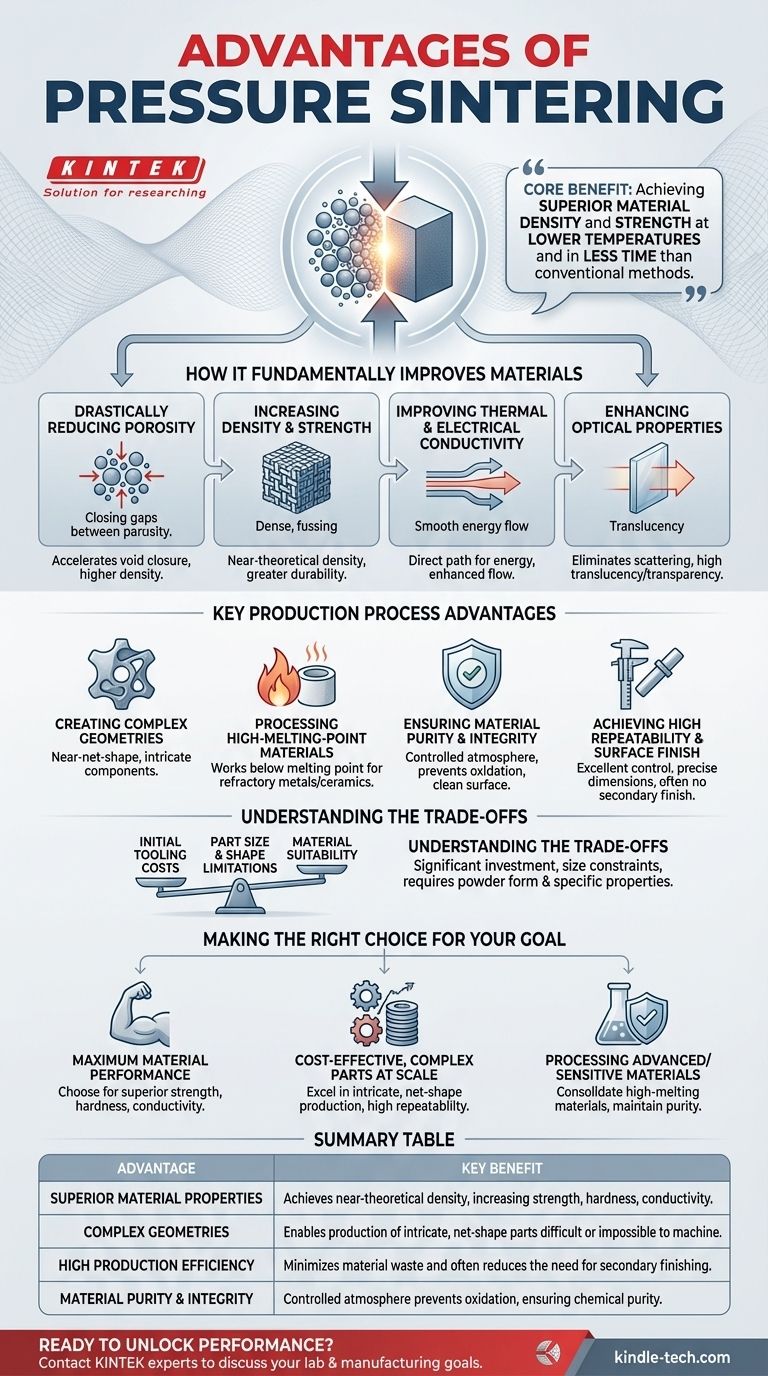

How Pressure Sintering Fundamentally Improves Materials

The application of external force during the sintering cycle is not just an enhancement; it fundamentally changes the consolidation mechanism of the powdered material, leading to significant improvements across key physical properties.

Drastically Reducing Porosity

Sintering works by forming "necks" between individual particles, gradually closing the gaps, or pores, between them. Applying pressure physically forces these particles together, accelerating the closure of these voids far more effectively than heat alone.

Increasing Density and Strength

Porosity is the enemy of strength. By achieving a much lower level of porosity, pressure sintering produces parts with significantly higher density. This near-theoretical density directly translates to superior mechanical properties, including greater strength and durability.

Improving Thermal and Electrical Conductivity

Gaps and pores between material particles act as insulators, impeding the flow of energy. A denser, less porous material created through pressure sintering provides a more direct path for heat and electricity to travel, enhancing its conductivity.

Enhancing Optical Properties

For certain materials, particularly ceramics, internal pores scatter light, making the material opaque. By eliminating these pores, pressure sintering can produce materials with high translucency or even transparency.

Key Advantages in the Production Process

Beyond the final material properties, pressure sintering offers distinct advantages that make it a highly effective and often irreplaceable manufacturing method for demanding applications.

Creating Complex Geometries

Because the process starts with a powder, it can form highly complex, non-machinable, and near-net-shape parts. This allows for the mass production of intricate components that would be prohibitively expensive or impossible to create using traditional subtractive manufacturing.

Processing High-Melting-Point Materials

Pressure sintering operates below the material's melting point. This is a critical advantage for working with advanced materials like technical ceramics or refractory metals (e.g., tungsten), which have extremely high melting points and are difficult to process via casting.

Ensuring Material Purity and Integrity

Modern pressure sintering furnaces operate with a precisely controllable atmosphere, often a vacuum or inert gas. This prevents oxidation and decarbonization, ensuring the chemical purity of the material and resulting in parts with less distortion and no surface contamination.

Achieving High Repeatability and Surface Finish

The process offers excellent control over final part dimensions and tolerances, making it highly repeatable for both low- and high-volume production runs. Furthermore, sintered parts often have an excellent surface finish right out of the furnace, reducing or eliminating the need for secondary finishing operations.

Understanding the Trade-offs

While powerful, pressure sintering is not the universal solution for every application. Understanding its limitations is key to making an informed decision.

Initial Tooling and Equipment Costs

The presses, furnaces, and molds required for pressure sintering represent a significant capital investment. This generally makes the process most cost-effective for medium-to-high volume production runs where the initial costs can be amortized.

Limitations on Part Size and Shape

The need to apply high, uniform pressure across the entire part can limit the maximum size of the components that can be produced. Additionally, the design must allow for the even compaction of powder, which can place some constraints on geometry.

Material Suitability

While the process is versatile, not all materials are suitable for pressure sintering. The material must be available in a powdered form and possess characteristics that allow it to compact and bond effectively under heat and pressure.

Making the Right Choice for Your Goal

To determine if pressure sintering is the correct approach, consider your primary objective.

- If your primary focus is maximum material performance: Choose pressure sintering for its unparalleled ability to achieve near-theoretical density, leading to superior strength, hardness, and conductivity.

- If your primary focus is cost-effective, complex parts at scale: This process excels at producing intricate, net-shape components with high repeatability, minimizing material waste and post-processing.

- If your primary focus is processing advanced or sensitive materials: Use pressure sintering to effectively consolidate high-melting-point materials while maintaining absolute chemical purity in a controlled, non-oxidizing atmosphere.

Ultimately, pressure sintering empowers engineers and designers to create high-performance components that would otherwise be technically or economically unfeasible.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Superior Material Properties | Achieves near-theoretical density, increasing strength, hardness, and conductivity. |

| Complex Geometries | Enables production of intricate, net-shape parts difficult or impossible to machine. |

| High Production Efficiency | Minimizes material waste and often reduces the need for secondary finishing. |

| Material Purity & Integrity | Controlled atmosphere prevents oxidation, ensuring chemical purity. |

Ready to unlock the performance of pressure sintering for your lab?

KINTEK specializes in the advanced lab equipment and consumables required for precise pressure sintering processes. Whether you are developing new materials or scaling up production of high-performance components, our expertise and solutions can help you achieve superior density, complex geometries, and exceptional material properties.

Contact our experts today to discuss how we can support your specific laboratory and manufacturing goals.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does the uniaxial pressing function of a vacuum hot press furnace influence the microstructure of ZrC-SiC ceramics?

- What advantages does hot pressing sintering equipment provide for NASICON? Achieve 100% Dense Solid Electrolyte Plates

- What are the advantages of using a vacuum hot press sintering furnace? Achieve 99.1% Density in CuW30 Composites

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- What role does a high-temperature hot press play in the sintering of NITE-SiC? Optimize Your Densification Process