The primary advantages of sieve testing are its simplicity, speed, and cost-effectiveness. As a foundational method for particle size analysis, it delivers accurate and reproducible results with minimal equipment and training, making it an industry standard for quality control across numerous sectors.

Sieve analysis is the benchmark for particle sizing when the goal is reliability and efficiency rather than extreme precision. Its strength lies in providing a straightforward, affordable, and highly repeatable method for verifying that materials meet established specifications.

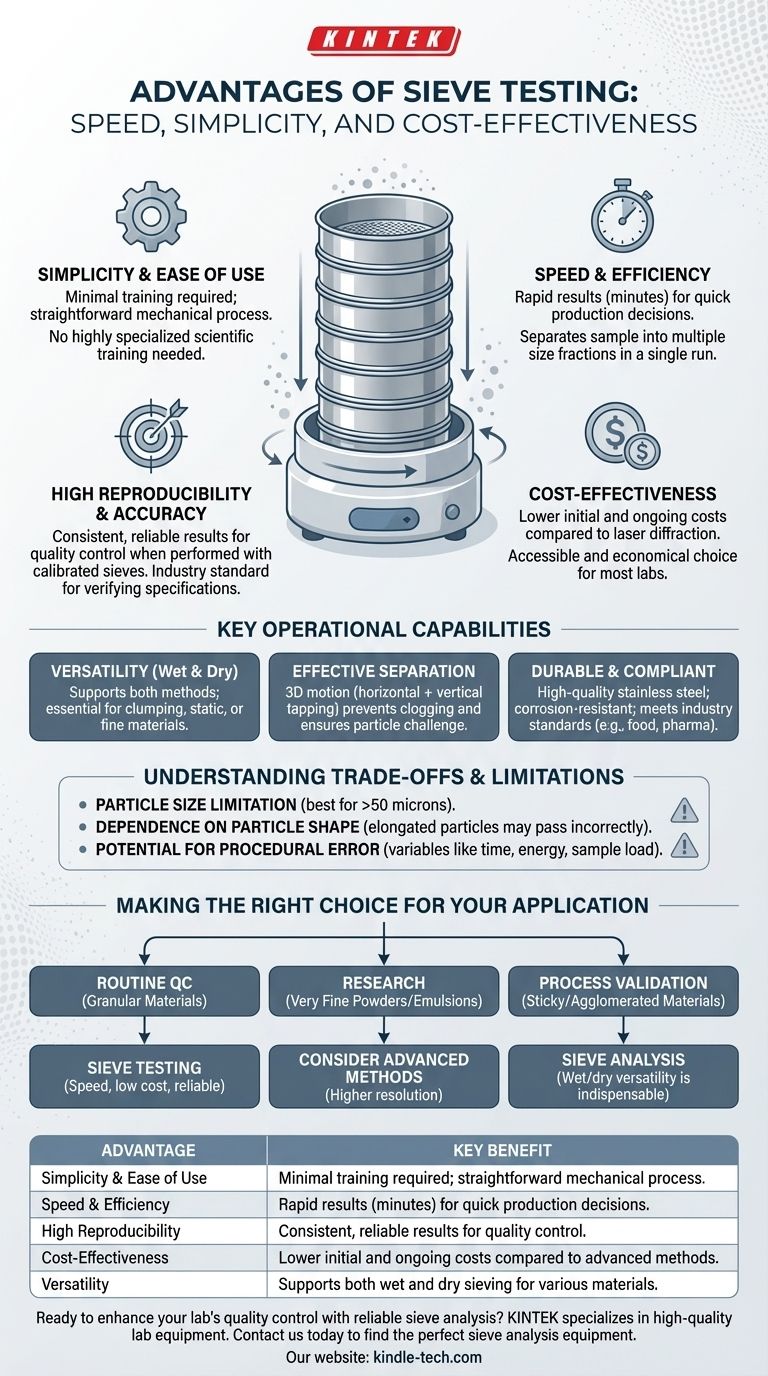

The Core Benefits of Sieve Analysis

Sieve testing, often automated with a sieve shaker, remains a dominant method for particle analysis because its core benefits align directly with the practical needs of production and quality assurance environments.

Simplicity and Ease of Use

The principle of sieve testing is fundamentally mechanical: passing a sample through a stack of screens with progressively smaller mesh openings. The equipment is easy to set up, and the procedure does not require operators with highly specialized scientific training, reducing operational complexity.

Speed and Efficiency

A standard sieve analysis can be completed in a matter of minutes. This rapid feedback is critical in a production setting where immediate decisions about a batch's quality are required. Furthermore, the ability to stack multiple sieves allows for the separation of a sample into several size fractions in a single, efficient run.

High Reproducibility and Accuracy

When performed with calibrated sieves and a consistent procedure, sieve analysis provides highly reproducible results. This consistency is the reason it is so trusted for quality control; it reliably confirms whether a material like sand, grain, or a chemical powder falls within its required size distribution.

Cost-Effectiveness

Compared to more complex methods like laser diffraction or image analysis, the initial investment for a sieve shaker and a set of certified sieves is significantly lower. The ongoing operational costs are also minimal, making it an accessible and economical choice for most labs.

Key Operational Capabilities

Modern sieve shakers have evolved to handle a wider range of materials with greater efficiency, expanding the utility of this traditional technique.

Versatility for Wet and Dry Sieving

While dry sieving is the most common method, many shakers also support wet sieving. This is essential for materials that are prone to clumping, have high static electricity, or are extremely fine. Using a liquid (typically water) helps disperse the particles and wash them through the mesh, ensuring an accurate analysis.

Effective Particle Separation

Modern shakers utilize a 3D motion, combining a horizontal circular movement with a vertical tapping action. This motion continuously reorients the particles on the mesh surface, ensuring each particle is challenged against the openings and preventing the mesh from becoming clogged or "blinded."

Durable and Compliant Construction

Sieves and shakers are typically constructed from high-quality stainless steel. This provides excellent durability and resistance to corrosion, which is critical for maintaining the integrity and certified diameter of the mesh openings over time. It is also a requirement for use in food, pharmaceutical, and other regulated industries.

Understanding the Trade-offs and Limitations

While powerful, sieve analysis is not the solution for every scenario. Understanding its limitations is key to using it appropriately.

The Particle Size Limitation

Sieve analysis is excellent for granular materials and powders, but its effectiveness diminishes for very fine particles. Generally, it is best suited for particles larger than 50 microns. For sub-micron analysis required in nanotechnology or advanced materials, methods like laser diffraction are superior.

Dependence on Particle Shape

Sieving fundamentally measures a particle based on the size of the hole it can pass through. This means elongated or flat particles (like needles or flakes) can pass through a mesh end-on or diagonally, leading to a result that doesn't accurately represent their true size.

Potential for Procedural Error

Although the process is simple, results can be influenced by variables like the sieving time, the energy of the shaker, and the amount of sample loaded. Inconsistent procedures or using worn, damaged sieves can introduce variability and reduce the accuracy of the results.

Making the Right Choice for Your Application

To decide if sieve analysis fits your needs, consider your primary objective.

- If your primary focus is routine quality control for granular materials: Sieve testing is likely your best choice due to its speed, low cost, and trusted reliability.

- If your primary focus is research on very fine powders or emulsions: You should consider more advanced methods like laser diffraction, which provide higher resolution for sub-micron particles.

- If your primary focus is process validation with sticky or agglomerated materials: The ability to perform both wet and dry sieving makes this a versatile and indispensable tool for your lab.

By understanding both its powerful advantages and its practical limitations, you can confidently determine if sieve analysis is the right tool to achieve your material characterization goals.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Simplicity & Ease of Use | Minimal training required; straightforward mechanical process. |

| Speed & Efficiency | Rapid results (minutes) for quick production decisions. |

| High Reproducibility | Consistent, reliable results for quality control. |

| Cost-Effectiveness | Lower initial and ongoing costs compared to advanced methods. |

| Versatility | Supports both wet and dry sieving for various materials. |

Ready to enhance your lab's quality control with reliable sieve analysis?

KINTEK specializes in providing high-quality lab equipment and consumables, including durable sieve shakers and certified test sieves, to meet your laboratory's precise particle sizing needs. Our solutions are designed for accuracy, durability, and compliance with industry standards.

Contact us today to find the perfect sieve analysis equipment for your application and ensure your materials meet specification every time.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- Is a dry sieve analysis more accurate than a washed sieve analysis? Choosing the Right Method for Your Material

- What are the uses of sieve in laboratory? Essential Guide to Particle Size Analysis

- What is the significance of using precision standard sieves for Inconel 625/TiB2? Optimize DLD Powder Quality

- What are the steps in sieving method? A Guide to Accurate Particle Size Separation

- Why is a 200-mesh sieve required for LCFA ceramic membrane precursor powders? Ensure Defect-Free Membrane Fabrication

- How do you calculate sieve analysis in a lab report? A Step-by-Step Guide to Accurate Particle Size Distribution

- What are the errors of particle size analysis by sieving? Avoid Costly Mistakes in Your Lab

- What is the difference between wet sieve analysis and dry sieve analysis? Choose the Right Method for Your Material