The primary advantage of twin-screw granulation (TSG) is its unique ability to operate as a continuous manufacturing process, offering unparalleled control over granule attributes. Unlike traditional batch methods, TSG integrates multiple steps into a single, compact unit, resulting in a more efficient, consistent, and scalable operation from early development through to full-scale production.

Twin-screw granulation is not simply an alternative granulation technique; it is a foundational technology for the pharmaceutical industry's shift away from inefficient batch processing toward modern, highly controlled continuous manufacturing.

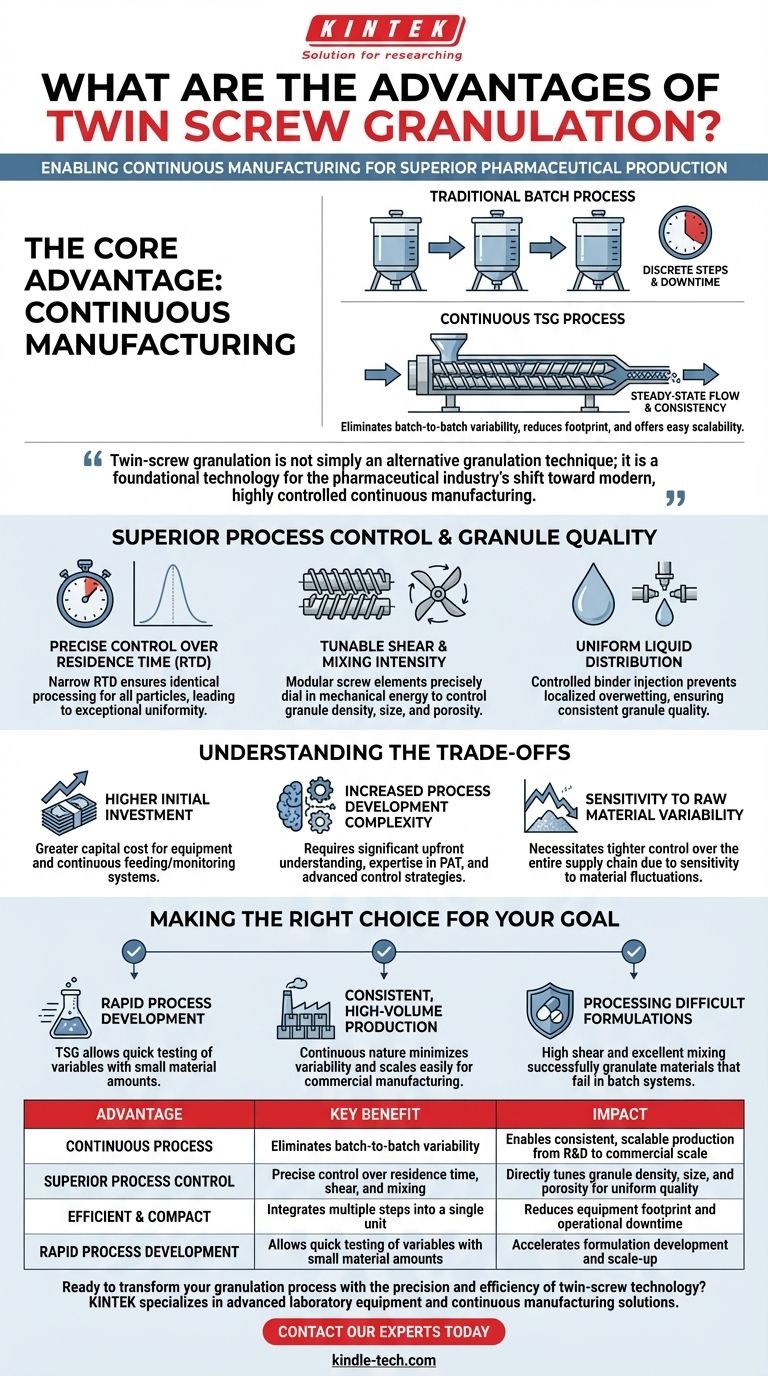

The Core Advantage: Enabling Continuous Manufacturing

Twin-screw granulation is fundamentally different from older batch technologies like high-shear or fluid-bed granulation. Its design is purpose-built for a continuous flow of material.

From Batch to Continuous

In traditional batch manufacturing, large quantities of material are processed in discrete steps, with the entire batch moving from one piece of equipment to the next. This creates significant downtime and introduces variability between batches.

Continuous manufacturing, enabled by TSG, processes a constant stream of material. Raw powders and liquid binders are fed continuously into one end of the granulator, and finished granules exit from the other in a steady state.

Why Continuous is Superior

This shift eliminates batch-to-batch variability, a major challenge in pharmaceutical quality control. It also allows for a much smaller equipment footprint and the ability to produce any amount of material needed—from a few kilograms to many tons—simply by running the process for a longer duration.

Superior Process Control and Granule Quality

The design of the twin-screw granulator provides a level of process control that is impossible to achieve in batch systems. The two co-rotating screws inside the barrel create a highly controlled environment.

Precise Control Over Residence Time

The screw configuration and rotation speed precisely determine the Residence Time Distribution (RTD)—the amount of time the material spends inside the granulator. A narrow RTD means all particles undergo nearly identical processing, leading to exceptional product uniformity.

Tunable Shear and Mixing Intensity

The screws are modular and can be assembled with different types of "elements" (e.g., conveying, kneading, mixing). By changing these elements, formulators can precisely dial in the amount of mechanical energy (shear) and mixing intensity applied to the powder, directly controlling granule density, size, and porosity.

Uniform Liquid Distribution

Liquid binder is introduced through one or more injection ports along the barrel. This allows for extremely uniform distribution and prevents the localized overwetting that often plagues batch processes, resulting in more consistent granule quality.

Understanding the Trade-offs

While powerful, TSG is not a universal solution. Adopting this technology requires a clear understanding of its demands and limitations.

Higher Initial Investment

The initial capital cost for a twin-screw granulator and the associated continuous feeding and monitoring systems is typically higher than for traditional batch equipment.

Increased Process Development Complexity

Developing a robust continuous process requires significant upfront investment in process understanding. It demands expertise in Process Analytical Technology (PAT) to monitor the process in real-time and establish advanced control strategies.

Sensitivity to Raw Material Variability

Continuous processes, including TSG, can be more sensitive to fluctuations in the physical properties of incoming raw materials (like particle size or density). This necessitates tighter control over the entire supply chain.

Making the Right Choice for Your Goal

Adopting twin-screw granulation depends entirely on your strategic objective.

- If your primary focus is rapid process development: TSG is ideal because it allows you to test numerous formulation and process variables quickly using very small amounts of material.

- If your primary focus is consistent, high-volume production: The continuous nature of TSG minimizes variability and scales easily, making it the superior choice for commercial manufacturing.

- If your primary focus is processing a difficult or sensitive formulation: The high shear and excellent mixing control of TSG can successfully granulate materials that fail in lower-energy batch systems.

Ultimately, twin-screw granulation represents a more deliberate, data-driven, and controllable approach to creating high-quality pharmaceutical products.

Summary Table:

| Advantage | Key Benefit | Impact |

|---|---|---|

| Continuous Process | Eliminates batch-to-batch variability | Enables consistent, scalable production from R&D to commercial scale |

| Superior Process Control | Precise control over residence time, shear, and mixing | Directly tunes granule density, size, and porosity for uniform quality |

| Efficient & Compact | Integrates multiple steps into a single unit | Reduces equipment footprint and operational downtime |

| Rapid Process Development | Allows quick testing of variables with small material amounts | Accelerates formulation development and scale-up |

Ready to transform your granulation process with the precision and efficiency of twin-screw technology? KINTEK specializes in providing advanced laboratory equipment and consumables to meet your specific needs. Whether you are developing a new formulation or scaling up production, our expertise in continuous manufacturing solutions can help you achieve superior control, consistency, and scalability. Contact our experts today to discuss how twin-screw granulation can benefit your laboratory or production facility!

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

- Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

People Also Ask

- Why are high-pressure autoclaves essential for preparing bio-based polyamide curing agents from dimeric acid?

- What is the contribution of a hydrothermal reactor to graded pore construction? Precision Templates for TAS

- How does a high-pressure reactor demonstrate its value in accelerated aging? Predict Catalyst Durability Fast

- What is the role of high-pressure reactors in the study of alloy oxidation? Essential Tools for Supercritical Research

- What is the purpose of using a high-temperature hydrothermal reactor? Enhance Iodine@Activated Carbon Cathode Synthesis