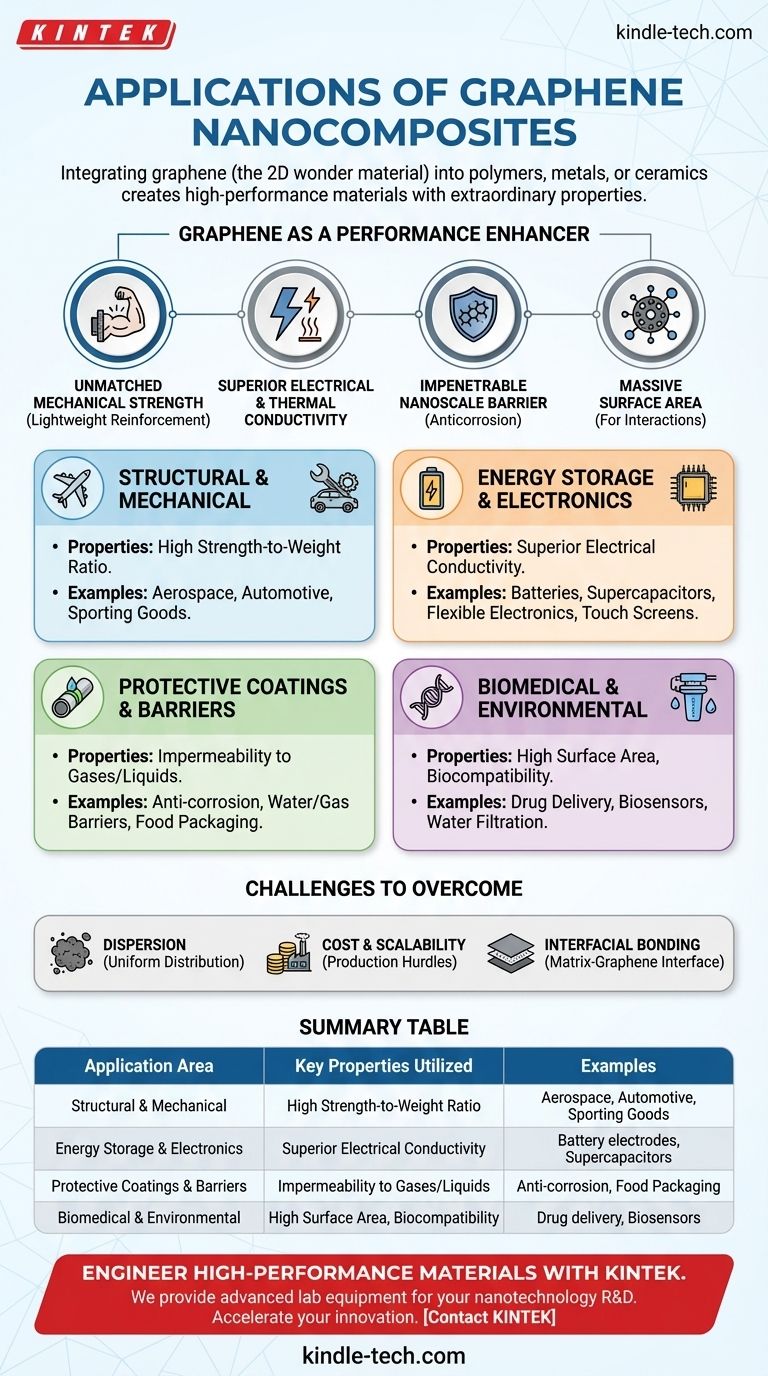

In short, graphene nanocomposites are being applied in fields ranging from aerospace engineering and electronics to energy storage and biomedicine. By integrating graphene into materials like polymers, metals, or ceramics, these composites gain extraordinary new properties, such as immense strength, high electrical conductivity, and superior chemical resistance.

The true value of graphene nanocomposites lies in their ability to combine the inherent properties of a base material with graphene's exceptional characteristics. This creates a new class of high-performance materials tailored for specific, demanding applications that were previously out of reach.

What Makes Graphene a Game-Changer in Composites?

Graphene is not simply an additive; it is a fundamental performance enhancer. Its two-dimensional, single-atom-thick structure imparts a unique combination of properties that transform the host material.

Unmatched Mechanical Strength

Graphene is one of the strongest materials ever tested. When dispersed correctly within a polymer or metal matrix, it acts as a nanoscale reinforcement, drastically increasing the composite's strength and stiffness without adding significant weight.

Superior Electrical and Thermal Conductivity

While most polymers are insulators, adding a small amount of graphene can make them electrically conductive. This is critical for applications like anti-static coatings, conductive inks, and advanced battery electrodes. Its high thermal conductivity also allows it to dissipate heat effectively.

An Impenetrable Barrier at the Nanoscale

Graphene's tightly packed carbon lattice is impermeable to almost all gases and liquids. When layered within a composite coating, it creates a tortuous path that prevents corrosive molecules from reaching the substrate, leading to exceptional anticorrosion protection.

A Massive Surface Area

Due to its single-atom thickness, graphene has an extremely high surface-area-to-volume ratio. This makes it an ideal platform for applications that depend on surface interactions, such as catalysts, sensors, and drug delivery systems where molecules can be attached to its surface.

Key Application Areas of Graphene Nanocomposites

The unique properties of graphene translate directly into a wide and growing range of practical uses.

Structural and Mechanical Reinforcement

Graphene's strength-to-weight ratio is a primary driver of its use in composites. Applications include lightweight components for aerospace and automotive industries, stronger and lighter sporting equipment, and reinforced plastics.

Energy Storage and Electronics

The high electrical conductivity of graphene is revolutionizing energy solutions. It is used to create more efficient electrodes for batteries and supercapacitors, enabling faster charging and higher capacity. It's also used in transparent conductive films for touch screens and flexible electronics.

Protective Coatings and Barriers

Leveraging its impermeability, graphene-polymer composites are used to create advanced coatings. These provide superior protection against corrosion, water, and gas penetration for everything from steel structures to food packaging.

Biomedical and Environmental Applications

Graphene's high surface area and biocompatibility (in certain forms) open doors in medicine. It is being researched for targeted drug delivery systems, highly sensitive biosensors for diagnostics, and as a membrane material for advanced water filtration.

Understanding the Trade-offs and Challenges

While the potential is immense, the practical application of graphene nanocomposites is not without its difficulties. Acknowledging these challenges is key to successful implementation.

The Challenge of Dispersion

To be effective, graphene sheets must be evenly distributed throughout the host material without clumping. Achieving this uniform dispersion on an industrial scale remains a significant technical hurdle. Poor dispersion leads to weak spots and negates the potential benefits.

Cost and Scalability

The production of high-quality, defect-free graphene is still relatively expensive compared to traditional materials. While costs are decreasing, scaling up production to meet the demands of mass-market applications is an ongoing challenge.

Interfacial Bonding

The performance of the composite depends heavily on the bond between the graphene and the matrix material. Engineering a strong interface is complex and crucial for transferring stress and other properties from the matrix to the graphene reinforcement.

Making the Right Choice for Your Goal

The optimal graphene composite depends entirely on the problem you are trying to solve.

- If your primary focus is mechanical strength: Prioritize composites with well-dispersed, high-quality graphene sheets in a robust polymer or epoxy matrix.

- If your primary focus is conductivity: Select composites where the graphene loading is sufficient to form a percolating network for electrical or thermal transfer.

- If your primary focus is barrier performance: Look for composites that create a layered, "brick-and-mortar" structure to maximize impermeability.

- If your primary focus is active surface area: Use composites based on graphene oxide or functionalized graphene designed for chemical or biological interaction.

Ultimately, graphene nanocomposites offer a powerful platform for engineering materials with precisely tailored, high-performance characteristics.

Summary Table:

| Application Area | Key Properties Utilized | Examples |

|---|---|---|

| Structural & Mechanical Reinforcement | High Strength-to-Weight Ratio | Aerospace components, automotive parts, sporting goods |

| Energy Storage & Electronics | Superior Electrical Conductivity | Battery electrodes, supercapacitors, flexible electronics |

| Protective Coatings & Barriers | Impermeability to Gases/Liquids | Anti-corrosion coatings, food packaging |

| Biomedical & Environmental | High Surface Area, Biocompatibility | Drug delivery systems, biosensors, water filtration membranes |

Ready to engineer high-performance materials with graphene nanocomposites? KINTEK specializes in providing advanced lab equipment and consumables to support your research and development in nanotechnology. Whether you're working on next-generation batteries, protective coatings, or biomedical devices, our solutions can help you achieve precise material synthesis and analysis. Contact our experts today to discuss how we can accelerate your innovation in graphene applications.

Visual Guide

Related Products

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- Electrode Polishing Material for Electrochemical Experiments

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- How long does it take to solder? A guide to timing and technique for perfect joints

- What is the maximum temperature for ceramics? Find the Right Material for Your High-Temp Application

- What are the strengths of brazing? Achieve Strong, Clean, and Precise Metal Joining

- Why is a hexagonal Boron Nitride (h-BN) layer required for LATP? Protect Your Samples from Carbon Contamination

- What are the disadvantages of brazing? Understanding the key limitations and trade-offs.