At its core, a hydraulic press is a tool for applying immense, controlled force. Its applications span nearly every major industry, used for everything from shaping metal parts for aerospace and automotive manufacturing to crushing cars for recycling and compressing powders for pharmaceuticals and food production. The machine's versatility comes from its simple yet powerful principle: using fluid pressure to multiply a small input force into a powerful output.

The true value of a hydraulic press lies not in a single function, but in its fundamental ability to shape, compress, form, or crush almost any material with precision. This makes it one of the most foundational and adaptable machines in modern manufacturing and industrial processing.

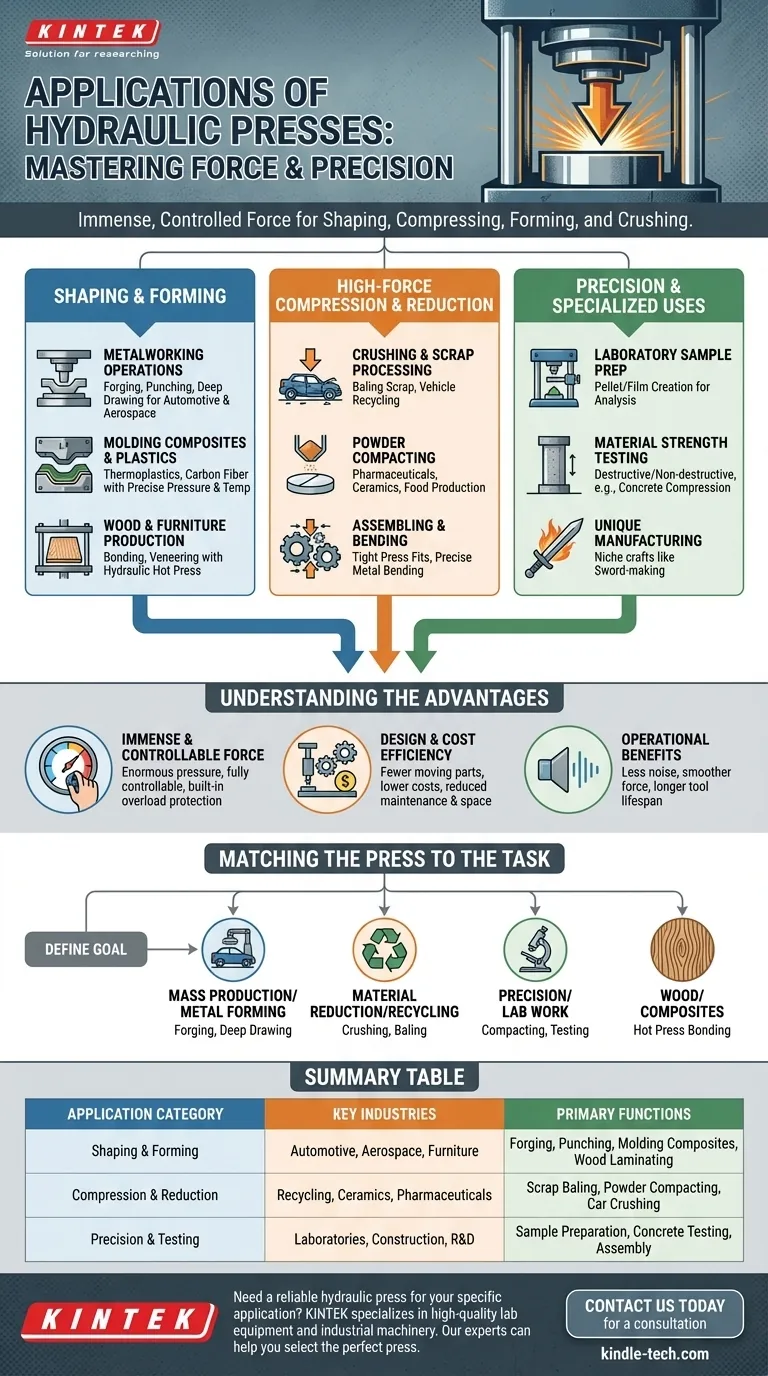

Core Industrial Applications: Shaping and Forming

The most common use of hydraulic presses is to shape and form raw materials into finished or semi-finished parts. This is the bedrock of heavy manufacturing.

Metalworking Operations

A hydraulic press is essential for manipulating metal. It is used for forging, punching, blanking, clinching, and deep drawing operations, transforming flat sheets of metal into complex components like car body panels.

Molding Composites and Plastics

In industries like aerospace and automotive, hydraulic presses are used for molding advanced materials. This includes thermoplastics, composites, and carbon fiber components, where precise pressure and temperature are critical.

Wood and Furniture Production

A specialized hydraulic hot press is used in woodworking. It bonds materials together by applying heat and pressure, essential for creating furniture, wooden doors, and applying decorative veneers and laminates.

High-Force Compression and Reduction

The immense tonnage a hydraulic press can generate makes it the ideal tool for processes that require reducing the size of an object or compacting loose material.

Crushing and Scrap Processing

One of the most well-known applications is crushing cars and other large metal objects. Hydraulic presses are also used for scrap baling, compressing discarded metal into dense, manageable blocks for recycling.

Powder Compacting

Many industries rely on presses to create solid forms from powders. This is seen in ceramics manufacturing, pharmaceuticals, and even food production, such as making fat-free cocoa powder.

Assembling and Bending

The controlled force of a hydraulic press is perfect for assembling parts that require a tight press fit. It is also used for precise bending of metal bars, plates, and structural components.

Precision and Specialized Uses

Beyond raw power, the control offered by a hydraulic system allows for its use in highly precise and specialized fields.

Laboratory Sample Preparation

In scientific and quality control labs, small hydraulic presses are used to prepare samples for analysis. This often involves pressing a material into a thin, uniform pellet or film.

Material Strength Testing

Engineers use hydraulic presses for destructive and non-destructive testing. A key example is concrete compression testing, where a press determines the load-bearing capacity of a concrete cylinder to ensure it meets safety standards.

Unique Manufacturing

The adaptability of the press allows for niche applications. Historically and in modern craft, it is used in processes like sword-making, where it helps forge and shape the blade with precision.

Understanding the Advantages

The widespread adoption of the hydraulic press is due to a clear set of technical and operational advantages over other machine types, like mechanical presses.

Immense and Controllable Force

The primary advantage is the ability to generate enormous pressure from a simple design. Importantly, this force is fully controllable throughout the stroke, and the machine has built-in overload protection, preventing damage.

Design and Cost Efficiency

Hydraulic presses have a simpler design with fewer moving parts than mechanical alternatives. This leads to lower initial and production costs, reduced maintenance, and a smaller required floor space.

Operational Benefits

These machines operate with less noise than mechanical stamping presses. The smooth application of force also results in a longer lifespan for the tools and dies used in the pressing operations.

Matching the Press to the Task

To select or understand a hydraulic press, you must first define the goal of the operation.

- If your primary focus is mass production and metal forming: The press is a cornerstone for forging, punching, and deep drawing parts in the automotive and appliance industries.

- If your primary focus is material reduction or recycling: Its immense power is perfectly suited for crushing vehicles and baling scrap metal efficiently.

- If your primary focus is precision or laboratory work: The controlled pressure is ideal for powder compacting, sample preparation, and material strength testing.

- If your primary focus is working with wood or composites: A hydraulic hot press is the essential tool for bonding, molding, and applying veneers with both heat and pressure.

Ultimately, the hydraulic press is an indispensable tool of modern industry, valued for its unparalleled ability to deliver massive, controlled force for a vast array of tasks.

Summary Table:

| Application Category | Key Industries | Primary Functions |

|---|---|---|

| Shaping & Forming | Automotive, Aerospace, Furniture | Forging, Punching, Molding Composites, Wood Laminating |

| Compression & Reduction | Recycling, Ceramics, Pharmaceuticals | Scrap Baling, Powder Compacting, Car Crushing |

| Precision & Testing | Laboratories, Construction, R&D | Sample Preparation, Concrete Testing, Assembly |

Need a reliable hydraulic press for your specific application?

KINTEK specializes in high-quality lab equipment and industrial machinery, including hydraulic presses tailored for metalworking, recycling, R&D, and more. Our experts can help you select the perfect press to enhance your productivity and precision.

Contact us today for a consultation and discover the KINTEK difference!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System