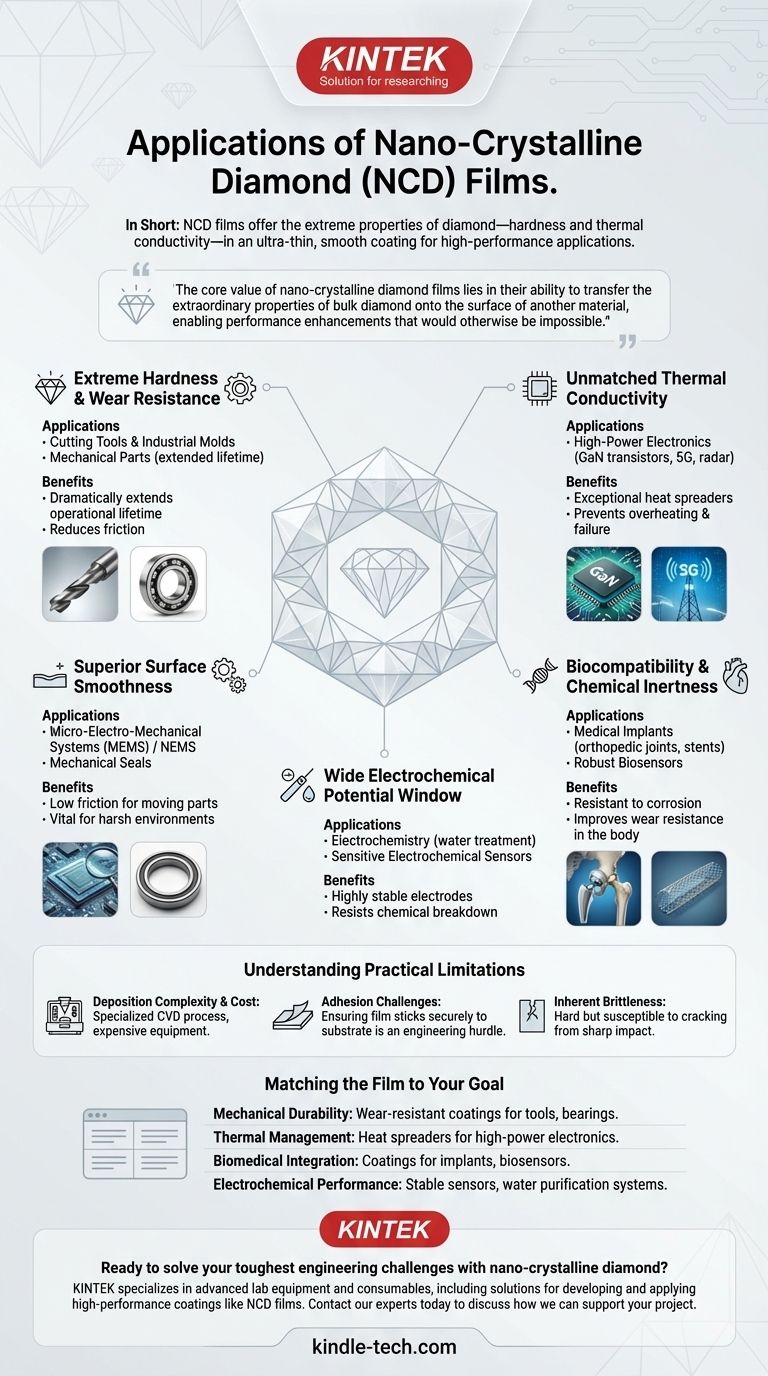

In short, nano-crystalline diamond (NCD) films are applied where a material needs the extreme properties of diamond—like hardness and thermal conductivity—but in the form of an ultra-thin, exceptionally smooth coating. This unique combination makes them critical for high-performance electronics, durable mechanical components, and advanced medical implants.

The core value of nano-crystalline diamond films lies in their ability to transfer the extraordinary properties of bulk diamond onto the surface of another material, enabling performance enhancements that would otherwise be impossible.

The Unique Properties Driving NCD Applications

To understand where NCD films are used, you must first understand the fundamental properties that make them so valuable. The applications are a direct result of the material's inherent characteristics, which are enhanced by its nano-scale crystal structure.

Extreme Hardness and Wear Resistance

Natural diamond is the hardest known material, and NCD films retain this property. The small grain size, typically less than 100 nanometers, creates an incredibly hard and tough surface.

This makes them ideal protective coatings for cutting tools, industrial molds, and mechanical parts, dramatically extending their operational lifetime and reducing friction.

Unmatched Thermal Conductivity

Diamond is the best thermal conductor known at room temperature, far surpassing materials like copper or silver. NCD films act as exceptional heat spreaders.

This is critical for managing heat in high-power electronics, such as Gallium Nitride (GaN) transistors used in 5G base stations and advanced radar systems. The NCD film efficiently pulls heat away from the active device, preventing overheating and failure.

Superior Surface Smoothness

Unlike older microcrystalline diamond films, which can be rough, the nano-scale grains of NCD create an ultra-smooth surface.

This smoothness is essential for Micro-Electro-Mechanical Systems (MEMS) and Nano-Electro-Mechanical Systems (NEMS), where low friction is required for moving parts. It is also vital for mechanical seals operating in harsh environments.

Biocompatibility and Chemical Inertness

Diamond is essentially carbon, making it highly biocompatible and resistant to corrosion or chemical attack. The body does not recognize it as a foreign substance, and it does not degrade in harsh chemical environments.

This allows NCD films to be used as coatings on medical implants, such as orthopedic joints or cardiovascular stents, to improve wear resistance and prevent adverse reactions. It also makes them ideal for creating robust biosensors.

Wide Electrochemical Potential Window

NCD films are excellent electrical insulators but can be doped (usually with boron) to become highly conductive electrodes. These electrodes are extremely stable and resist chemical breakdown even under high voltages.

This property is leveraged in electrochemistry for water treatment applications and for creating highly sensitive and durable electrochemical sensors designed to detect specific biological or chemical agents.

Understanding the Practical Limitations

While powerful, NCD films are not a universal solution. Acknowledging their trade-offs is crucial for successful implementation.

Deposition Complexity and Cost

Growing NCD films requires a specialized process called Chemical Vapor Deposition (CVD). This involves high temperatures and vacuum chambers, making the equipment and the process itself expensive compared to conventional coating methods.

Adhesion Challenges

Ensuring the diamond film sticks securely to the underlying material (the substrate) is a major engineering challenge. Poor adhesion can cause the coating to flake off or delaminate under stress, completely negating its benefits. Significant surface preparation and interlayer materials are often required.

Inherent Brittleness

Like all ceramics, diamond is very hard but also brittle. While NCD coatings are tough for their thickness, they can be susceptible to cracking or chipping from a sharp impact. The design of the underlying part must account for this.

Matching the Film to Your Goal

The right application depends entirely on which property of nano-crystalline diamond you need to leverage most.

- If your primary focus is mechanical durability: Use NCD films as wear-resistant coatings for cutting tools, bearings, or mechanical seals to dramatically increase their service life.

- If your primary focus is thermal management: Apply NCD as a heat spreader directly on high-power electronic devices to prevent thermal throttling and improve reliability.

- If your primary focus is biomedical integration: Coat medical implants with NCD to reduce wear and improve biocompatibility, or use it to build robust, long-lasting biosensors.

- If your primary focus is electrochemical performance: Fabricate NCD electrodes for creating highly stable sensors or for use in advanced water purification systems.

By understanding these core properties and trade-offs, you can effectively leverage nano-crystalline diamond to solve engineering challenges that are beyond the reach of conventional materials.

Summary Table:

| Application Area | Key NCD Property Leveraged |

|---|---|

| High-Power Electronics | Unmatched Thermal Conductivity (Heat Spreading) |

| Cutting Tools & Mechanical Parts | Extreme Hardness & Wear Resistance |

| Medical Implants & Biosensors | Biocompatibility & Chemical Inertness |

| MEMS/NEMS & Electrochemical Sensors | Surface Smoothness & Wide Electrochemical Window |

Ready to solve your toughest engineering challenges with nano-crystalline diamond?

KINTEK specializes in advanced lab equipment and consumables, including solutions for developing and applying high-performance coatings like NCD films. Whether you're in R&D for electronics, medical devices, or industrial components, our expertise can help you leverage the extreme properties of diamond to enhance your product's performance, durability, and reliability.

Contact our experts today to discuss how we can support your project with the right tools and materials.

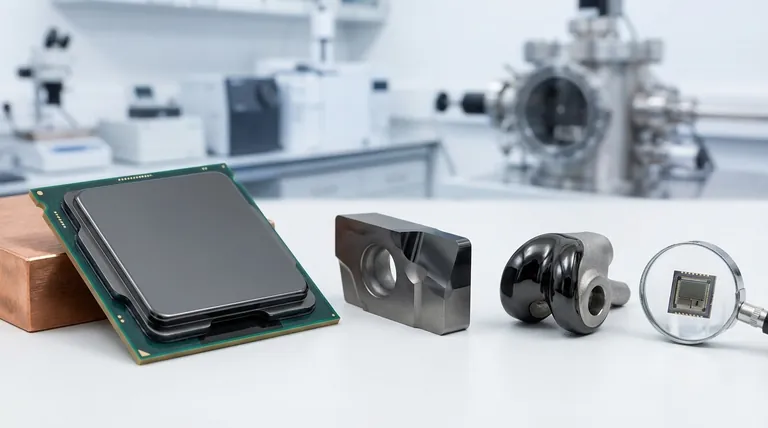

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Laboratory CVD Boron Doped Diamond Materials

- CVD Diamond Cutting Tool Blanks for Precision Machining

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Optical Windows for Lab Applications

People Also Ask

- What is the difference between CVD and original diamond? Choose the Right Diamond for Your Needs

- Can a diamond be created in a laboratory? The Science Behind Genuine Lab-Grown Diamonds

- What is microwave plasma chemical vapor deposition? A Guide to High-Purity Diamond Film Growth

- How long does it take to make a diamond in a machine? From Weeks to Billions of Years

- What are synthetic diamonds used for in industry? Powering High-Tech Tools and Electronics

- Can diamond be made artificially? Yes, with Identical Quality to Natural Diamonds

- Why is Microwave Plasma Chemical Vapor Deposition (MW-PCVD) preferred for BDD? Achieve Ultra-Pure Diamond Synthesis

- Can lab-grown diamonds be made into any shape? Discover the Limitless Possibilities of Custom Diamond Shapes