At its core, an optical thin film is an infinitesimally thin layer of material, often just a few atoms thick, applied to a surface to change how it interacts with light. These films are the invisible technology behind a vast array of modern products, including the anti-glare coatings on your eyeglasses, the energy-efficient tint on architectural glass, and the precision mirrors used in laser systems and solar panels.

The fundamental purpose of an optical thin film is to precisely control the reflection, transmission, and absorption of light. By engineering these layers at a scale smaller than a wavelength of light, we can create materials with optical properties that are impossible to achieve otherwise.

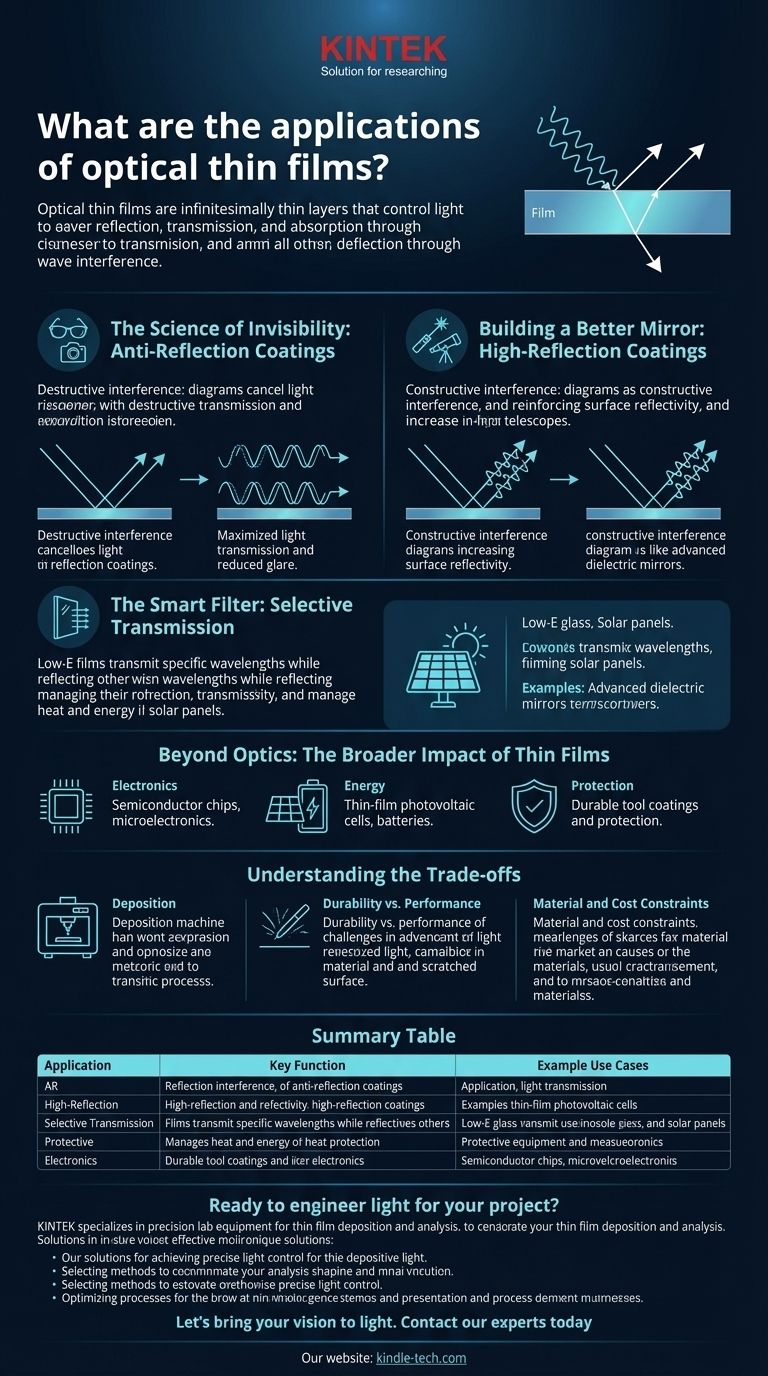

How a Thin Layer Bends Light to Our Will

The power of a thin film comes from a principle called wave interference. When light strikes a surface with a thin film, some of it reflects off the top of the film, and some reflects off the bottom surface (the substrate).

These two reflected light waves can either reinforce each other or cancel each other out, depending on the film's thickness and material.

The Science of Invisibility: Anti-Reflection Coatings

An anti-reflection (AR) coating is designed so that the two reflected light waves are perfectly out of phase, causing them to cancel each other out. This is called destructive interference.

The result is that almost no light is reflected, and nearly all of it passes through the material. This is critical for camera lenses, eyeglasses, and display screens, where maximizing light transmission and reducing glare is essential.

Building a Better Mirror: High-Reflection Coatings

Conversely, a high-reflection coating is engineered to make the reflected waves perfectly in-phase. This constructive interference dramatically increases the surface's reflectivity.

A simple household mirror uses a single metal film. However, advanced dielectric mirrors, used in lasers and scientific instruments, use dozens of alternating layers to achieve nearly 100% reflection for specific colors or wavelengths of light.

The Smart Filter: Selective Transmission

Thin films can also act as highly specific filters. They can be designed to transmit certain wavelengths of light while reflecting others.

This is the technology behind low-emissivity (Low-E) architectural glass, which allows visible light to pass through but reflects heat (infrared radiation), improving thermal insulation. It's also vital for solar cells, which need to absorb as much light as possible in a specific energy range.

Beyond Optics: The Broader Impact of Thin Films

While their optical properties are a primary application, the technology of depositing ultra-thin layers is foundational across many industries.

Electronics and Semiconductors

The entire microelectronics industry is built on thin films. The complex, layered structures of a semiconductor chip are created by depositing and etching successive thin films of conducting, insulating, and semiconducting materials.

Energy Generation and Storage

Thin-film photovoltaic cells use layers of material designed to absorb sunlight and convert it into electricity. This technology also extends to the development of next-generation thin-film batteries, enabling lighter and more flexible energy storage.

Protection and Durability

Thin films are widely used as protective coatings. Hard ceramic or metallic films can be applied to tools to increase their resistance to wear and corrosion, extending their operational life significantly.

Understanding the Trade-offs

While powerful, thin film technology is not without its challenges. The performance of a coating is directly tied to the quality of its deposition, a process that involves significant trade-offs.

The Challenge of Deposition

Creating a perfectly uniform film that is free of defects and adheres strongly to the substrate is a complex manufacturing process. Methods range from simple evaporation to highly controlled Molecular Beam Epitaxy (MBE), where layers are built one atom at a time. The chosen method directly impacts cost, speed, and final quality.

Durability vs. Performance

There is often a trade-off between a film's optical performance and its physical durability. An extremely precise multi-layer coating for a lab laser might be very sensitive to scratches or moisture, whereas a protective coating on a tool prioritizes hardness over optical purity.

Material and Cost Constraints

The choice of material dictates the achievable optical properties and the coating's durability. Some ideal materials are expensive or difficult to deposit reliably, forcing engineers to balance performance requirements with manufacturing cost and feasibility.

How to Apply This to Your Project

When specifying or evaluating a thin film, your primary goal will determine the ideal approach.

- If your primary focus is maximizing light transmission (e.g., lenses, displays): Your solution is a multi-layer anti-reflection (AR) coating designed to cancel reflections across the visible spectrum.

- If your primary focus is reflecting specific light (e.g., lasers, telescopes): You need a dielectric mirror, where alternating layers are precisely tuned to a target wavelength for maximum reflection.

- If your primary focus is managing heat and energy (e.g., smart windows, solar): The key is a selective coating that transmits visible light but blocks infrared and/or UV radiation.

- If your primary focus is durability (e.g., tools, outdoor components): Your choice will be a hard, protective coating where optical characteristics are secondary to wear and corrosion resistance.

Ultimately, mastering thin film technology is about engineering matter at the atomic level to command the flow of light.

Summary Table:

| Application | Key Function | Example Use Case |

|---|---|---|

| Anti-Reflection (AR) Coatings | Minimize light reflection | Eyeglasses, camera lenses, displays |

| High-Reflection Coatings | Maximize light reflection | Laser systems, scientific mirrors |

| Selective Transmission Filters | Transmit specific wavelengths | Low-E architectural glass, solar panels |

| Protective & Durable Coatings | Enhance wear and corrosion resistance | Industrial tools, outdoor components |

| Electronics & Semiconductors | Enable micro-scale circuitry | Semiconductor chips, microelectronics |

Ready to engineer light for your project?

KINTEK specializes in precision lab equipment and consumables for thin film deposition and analysis. Whether you are developing advanced optical coatings, semiconductor components, or durable protective layers, our solutions provide the reliability and precision required for cutting-edge research and manufacturing.

We help you:

- Achieve precise control over light reflection, transmission, and absorption.

- Select the right deposition methods and materials for durability and performance.

- Optimize your process for cost-efficiency without compromising quality.

Let’s bring your vision to light. Contact our experts today to discuss how KINTEK can support your laboratory and thin film technology needs.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Copper Foam

- Platinum Auxiliary Electrode for Laboratory Use

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is the plasma CVD process? Achieve Low-Temperature Thin Film Deposition

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition