In essence, Physical Vapor Deposition (PVD) is a high-tech coating process used to apply an extremely thin but durable film onto a surface. Its applications are vast, spanning from aerospace components and medical implants to cutting tools and decorative finishes, with the universal goal of improving a component's surface properties like hardness, wear resistance, and corrosion resistance.

The core value of PVD is not merely cosmetic; it is a fundamental engineering tool that allows you to enhance the performance and lifespan of a material by modifying its surface at a microscopic level, without altering the properties of the underlying component.

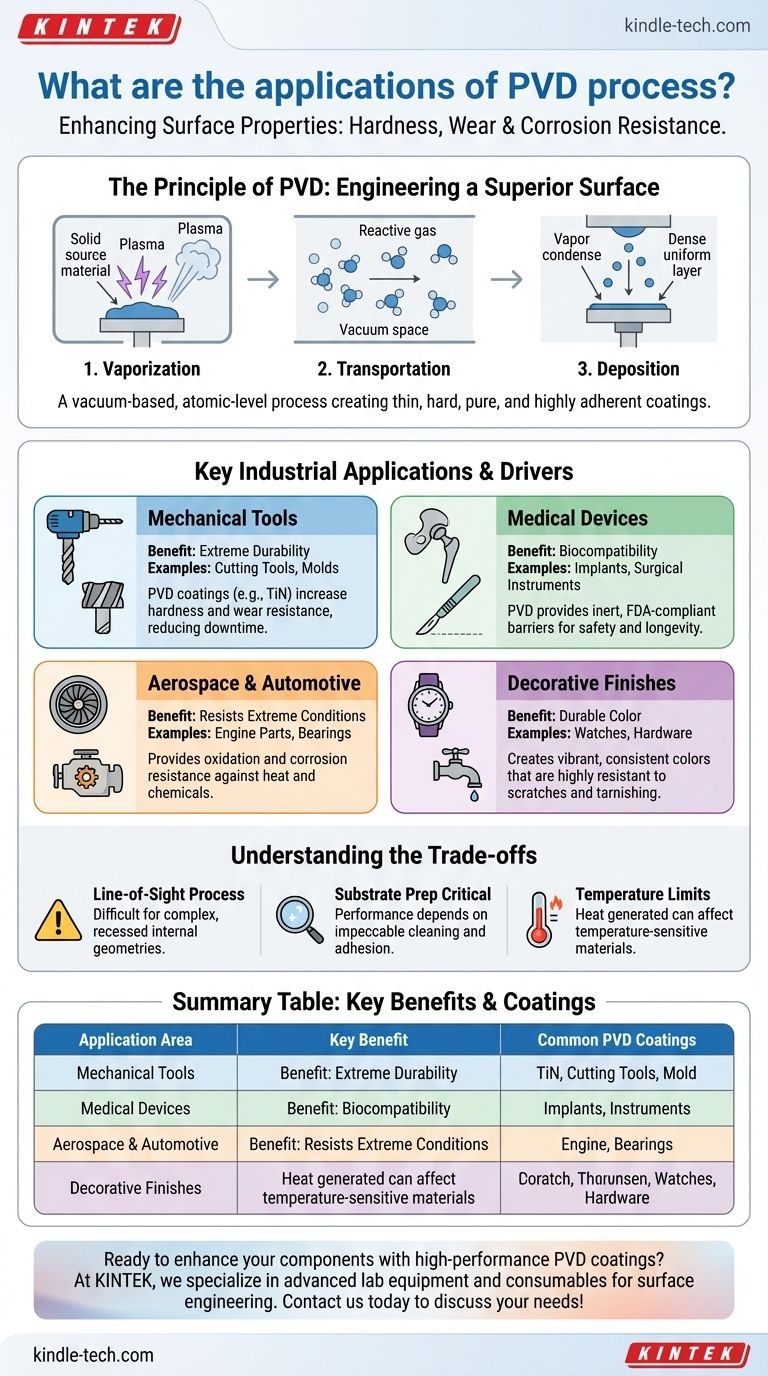

The Principle of PVD: Engineering a Superior Surface

Physical Vapor Deposition is a vacuum-based process. It fundamentally changes how a component interacts with its environment by adding a new, high-performance layer atom by atom.

How PVD Works: A Three-Step Process

The PVD process consists of three main stages conducted inside a high-vacuum chamber.

-

Vaporization: A solid source material (a metal like titanium or zirconium) is converted into a vaporous state. This is often achieved using high-energy plasma, such as through arc evaporation or magnetron sputtering.

-

Transportation: These vaporized atoms or molecules travel through the vacuum chamber, often with the help of a reactive gas (like nitrogen or oxygen) that will become part of the final coating.

-

Deposition: The vapor condenses onto the target component (the substrate), forming a thin, dense, and highly-adherent coating.

The Result: Thin, Hard, and Pure Coatings

This controlled, atomic-level process creates coatings that are exceptionally pure and uniform. Because it occurs in a vacuum, there are no contaminants to weaken the film. The resulting layer is extremely hard and bonded tightly to the substrate, providing performance benefits far beyond what the base material alone could offer.

Key Industrial Applications and Their Drivers

The applications for PVD are defined by the problems it solves. Industries use it when a component's surface is its primary point of failure or limitation.

For Mechanical Tools: Increasing Durability

This is one of the most common uses for PVD. Coating drill bits, milling cutters, and industrial molds dramatically increases their lifespan.

The primary drivers are wear resistance and hardness. A PVD coating like Titanium Nitride (TiN) makes the cutting edge significantly harder, allowing it to withstand abrasion and friction for longer, leading to more precise work and less downtime.

For Medical Devices: Ensuring Biocompatibility

PVD is critical for medical implants, surgical instruments, and dental devices. The process can meet stringent FDA requirements for safety.

The key benefit here is biocompatibility. The coatings are inert and non-toxic, creating a safe barrier between a metal implant (like a hip joint) and the human body. This prevents adverse reactions and improves the device's longevity.

For Aerospace and Automotive: Resisting Extreme Conditions

Components like turbine blades, engine parts, and bearings operate under immense stress, heat, and corrosive environments.

PVD provides crucial oxidation resistance and corrosion resistance. The dense coating acts as a shield, protecting the underlying metal from high-temperature degradation and chemical attack, which is essential for safety and performance.

For Decorative Finishes: Achieving Durable Color

PVD is used to create durable and attractive finishes on watches, faucets, eyewear, and hardware. Unlike paint or traditional plating, these colors are part of a hard ceramic layer.

While the goal is aesthetic, the driver is durability. PVD decorative coatings provide vibrant, consistent colors that are also highly resistant to scratches, tarnishing, and fading, ensuring the product looks new for much longer.

Understanding the Trade-offs and Considerations

While powerful, PVD is not a universal solution. Understanding its limitations is key to using it effectively.

It's a Line-of-Sight Process

PVD travels in a straight line from the source to the substrate. This makes it difficult to evenly coat complex internal geometries or deeply recessed features without sophisticated part rotation.

Substrate Preparation is Critical

The performance of a PVD coating is entirely dependent on its adhesion to the surface. The substrate must be impeccably cleaned and free of any oils, oxides, or contaminants before entering the vacuum chamber, adding a critical step to the manufacturing process.

Temperature Can Be a Limiting Factor

The PVD process generates significant heat. While this helps create a dense coating, it can be problematic for temperature-sensitive materials like certain plastics or low-temper-point metals, which could warp or deform.

Making the Right Choice for Your Goal

Deciding whether to use PVD depends entirely on the problem you need to solve.

- If your primary focus is extending tool life: PVD is a leading solution for improving hardness and lubricity on cutting and forming tools.

- If your primary focus is biocompatibility: PVD provides an inert, FDA-compliant barrier for medical implants and instruments.

- If your primary focus is a durable decorative finish: PVD offers a wide range of colors with scratch resistance far superior to paint or traditional plating.

- If your primary focus is corrosion or heat resistance: PVD creates a dense, non-porous barrier that protects components in harsh environments.

Ultimately, PVD empowers you to select a material for its core strength and cost while precisely engineering its surface for the specific demands of its environment.

Summary Table:

| Application Area | Key Benefit | Common PVD Coatings |

|---|---|---|

| Mechanical Tools | Extreme Hardness & Wear Resistance | Titanium Nitride (TiN), Titanium CarboNitride (TiCN) |

| Medical Devices | Biocompatibility & Corrosion Resistance | Titanium, Zirconium Nitride |

| Aerospace & Automotive | High-Temperature & Oxidation Resistance | Chromium Nitride (CrN), Aluminum Titanium Nitride (AlTiN) |

| Decorative Finishes | Scratch & Tarnish Resistance | Zirconium Nitride (for gold), Titanium Carbonitride (for rose/black) |

Ready to enhance your components with high-performance PVD coatings?

At KINTEK, we specialize in advanced lab equipment and consumables for surface engineering. Whether you are developing cutting tools, medical implants, or durable decorative finishes, our PVD solutions can help you achieve superior hardness, wear resistance, and biocompatibility.

Contact us today to discuss how our expertise can extend the lifespan and performance of your products!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating