In essence, radioactivity is used in industry as a unique and powerful tool for measurement, imaging, sterilization, and tracing where conventional methods are impractical or impossible. Common applications range from ensuring the structural integrity of welds and pipelines through radiography, to verifying the fill level of canned goods, to sterilizing medical equipment on a massive scale.

The core value of radioactivity in industry is its ability to provide precise, non-contact information from within sealed objects or complex processes. By harnessing the predictable behavior of radioactive decay, we gain an unparalleled ability to see, measure, and modify materials in ways that would otherwise be destructive or inefficient.

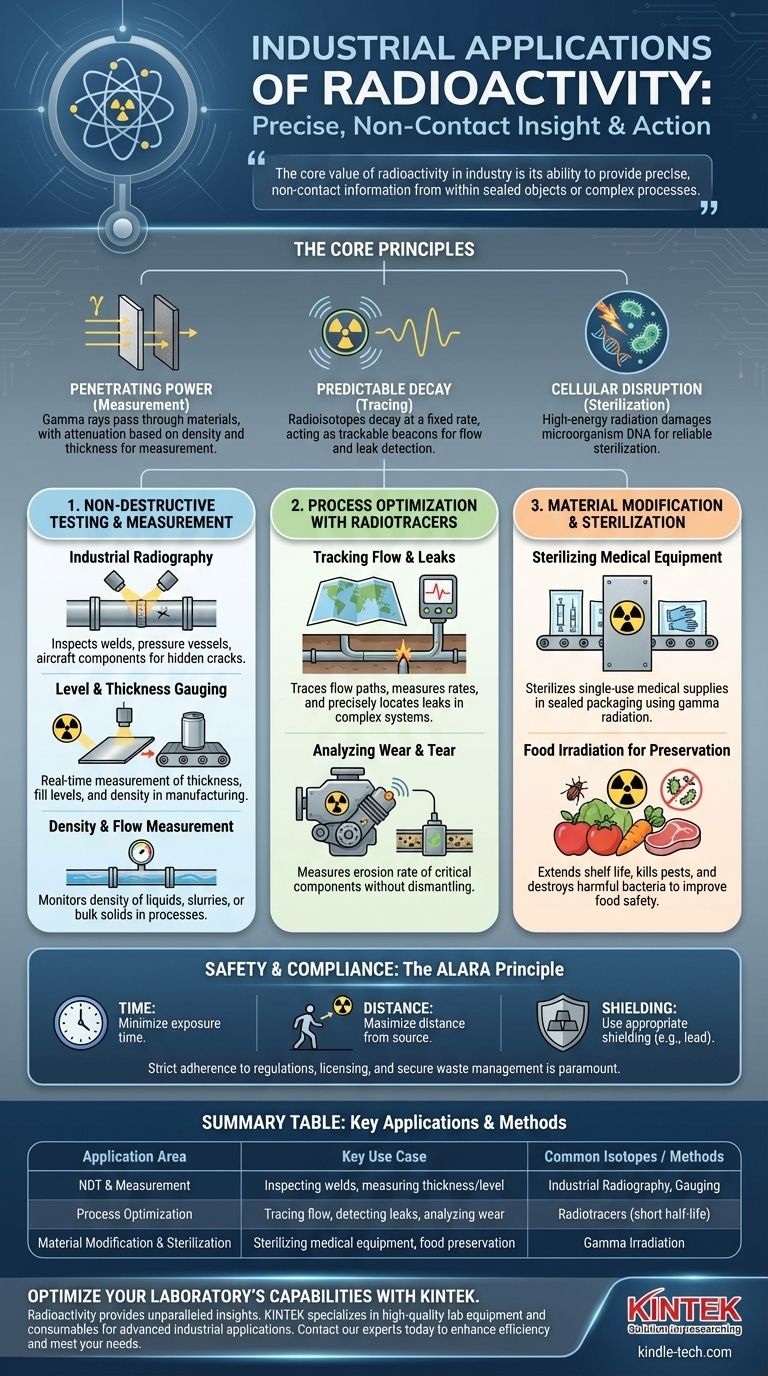

The Core Principle: How Radioactivity Enables Industrial Insight

To understand the applications, it's essential to grasp the fundamental properties of the radiation being used. Industrial uses primarily rely on gamma rays, which are high-energy photons.

Penetrating Power for Measurement

Gamma rays can pass through solid materials like steel, concrete, and product packaging. As they pass through, some are absorbed or scattered, a process called attenuation.

The denser or thicker the material, the more the gamma radiation is attenuated. By placing a radioactive source on one side of an object and a detector on the other, we can precisely measure thickness, density, or level based on how much radiation gets through.

Predictable Decay for Tracing

Radioactive isotopes, or radioisotopes, decay at a perfectly predictable rate. They act as microscopic beacons that can be tracked with sensitive detectors.

By introducing a small, safe amount of a specific radioisotope into a system—like a pipeline, a chemical reactor, or a machine component—we can trace its path, measure its flow rate, or detect leaks with extreme precision.

Cellular Disruption for Sterilization

High-energy radiation damages the DNA and other cellular structures of microorganisms like bacteria, viruses, and molds.

When applied in a controlled, high dose, this radiation can reliably sterilize objects without using high heat or harsh chemicals, which might damage the product itself.

Key Application 1: Non-Destructive Testing and Measurement

This is arguably the most widespread industrial use of radioactivity. It allows for quality control checks without damaging the final product, a practice known as non-destructive testing (NDT).

Industrial Radiography

Similar to a medical X-ray, industrial radiography uses a gamma source (like Iridium-192 or Cobalt-60) to create an image of the internal structure of a solid object.

This is critical for inspecting the integrity of welds in pipelines, pressure vessels, and aircraft components, revealing hidden cracks, voids, or flaws that could lead to catastrophic failure.

Level and Thickness Gauging

In manufacturing, consistency is key. Radioactive gauges provide continuous, real-time measurements. A source and detector are mounted across a moving sheet of metal, paper, or plastic to ensure its thickness remains within tight specifications.

This same principle is used to verify the fill level of cans, bottles, and packages on a high-speed production line, rejecting any that are under-filled without ever touching them.

Density and Flow Measurement

A nuclear density gauge can measure the density of liquids, slurries, or bulk solids moving through a pipe or on a conveyor belt. This is vital in mining, dredging, and food processing to monitor and control product consistency.

Key Application 2: Process Optimization with Radiotracers

Radiotracers provide insights into dynamic systems that are impossible to obtain otherwise. The amount of radioactive material used is typically minuscule and has a short half-life, ensuring it decays to background levels quickly.

Tracking Flow and Leaks

To find a leak in a vast network of underground pipes, a small amount of a gaseous or liquid radiotracer is injected into the system. Operators then scan the ground above the pipes with detectors, which will register a spike in radiation exactly where the material is escaping.

Analyzing Wear and Tear

To measure the erosion of critical engine components or the interior lining of a blast furnace, engineers can make a tiny spot on the surface radioactive. By monitoring the downstream fluid or material for traces of radioactivity, they can precisely calculate the rate of wear without dismantling the machinery.

Key Application 3: Material Modification and Sterilization

Here, the goal is not to measure but to use the energy of radiation to cause a specific physical or biological change.

Sterilizing Medical Equipment

A huge portion of single-use medical supplies—syringes, surgical gloves, sutures, and implants—are sterilized using gamma radiation from Cobalt-60.

The products are fully packaged and loaded onto a conveyor that passes them through a chamber with a powerful radiation source. The penetrating gamma rays sterilize the product inside its sealed packaging, a process that is more effective and less damaging for heat-sensitive plastics than steam sterilization.

Food Irradiation for Preservation

Irradiation is used to extend the shelf life of food and improve its safety. It can kill insects in grains and spices, inhibit the sprouting of potatoes and onions, and destroy harmful bacteria like Salmonella and E. coli in meat and poultry. The food itself does not become radioactive.

Understanding the Trade-offs and Safety Imperatives

While incredibly useful, the use of radioactive materials requires a strict and unwavering commitment to safety. The risks are well-understood and managed through robust protocols.

The Hazard of Ionizing Radiation

The same properties that make radiation useful can also make it dangerous. Ionizing radiation can damage living tissue, and exposure must be meticulously controlled.

The Principle of ALARA

The guiding philosophy of radiation safety is ALARA: As Low As Reasonably Achievable. This principle is implemented through three core actions:

- Time: Minimize the time spent near a radiation source.

- Distance: Maximize the distance from the source. Radiation intensity decreases dramatically with distance.

- Shielding: Use appropriate shielding (like lead or concrete) to block radiation.

Regulatory Oversight and Licensing

The use, transport, and disposal of radioactive sources are heavily regulated by national and international bodies (such as the Nuclear Regulatory Commission in the U.S.). Facilities must be licensed and are subject to regular inspections to ensure compliance with all safety procedures.

Waste Disposal and Source Management

Radioactive sources eventually decay to a point where they are no longer useful, becoming disused sources. These must be managed and disposed of according to strict federal regulations to prevent them from becoming an environmental or public health hazard.

How to Apply This to Your Goal

Your interest in industrial radioactivity likely stems from a specific professional context. Use these points to frame your understanding.

- If your primary focus is quality control and manufacturing: Concentrate on industrial radiography and nuclear gauging as essential tools for ensuring product integrity and consistency.

- If your primary focus is process engineering and efficiency: Understand that radiotracers are a diagnostic tool for optimizing flow, identifying inefficiencies, and performing predictive maintenance in complex systems.

- If your primary focus is public health and product safety: Recognize the critical role of gamma irradiation in sterilizing the vast majority of medical devices and enhancing food safety.

- If your primary focus is risk management and compliance: The ALARA principle and strict regulatory frameworks are the foundations that make the industrial use of these powerful materials safe and viable.

Radioactivity is an invisible but indispensable tool that underpins the quality, safety, and efficiency of countless industrial processes we rely on every day.

Summary Table:

| Application Area | Key Use Case | Common Isotopes / Methods |

|---|---|---|

| Non-Destructive Testing & Measurement | Inspecting welds, measuring thickness/level | Industrial Radiography (Iridium-192, Cobalt-60), Gauging |

| Process Optimization | Tracing flow, detecting leaks, analyzing wear | Radiotracers (short half-life isotopes) |

| Material Modification & Sterilization | Sterilizing medical equipment, preserving food | Gamma Irradiation (Cobalt-60) |

Optimize Your Laboratory's Capabilities with KINTEK

Radioactivity provides unparalleled insights for quality control, process efficiency, and product safety. Whether your lab focuses on materials testing, process engineering, or product sterilization, having the right equipment is crucial.

KINTEK specializes in providing high-quality lab equipment and consumables to support these advanced industrial applications. Our products help ensure precision, safety, and compliance in your operations.

Contact our experts today to discuss how KINTEK's solutions can enhance your laboratory's efficiency and meet your specific industrial needs.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Laboratory Horizontal Autoclave Steam Sterilizer Lab Microcomputer Sterilizer

People Also Ask

- What is the primary function of a laboratory Autoclave in seaweed hydrolysates? Sterilize and Optimize Fermentation

- What is the necessity of using an autoclave for pre-treating culture media? Ensure Accurate Ag2O/TiO2 Testing

- How does a laboratory autoclave ensure the success of long-cycle continuous fermentation processes? Secure Pure Strains

- Why is a laboratory autoclave necessary for Postgate Medium B (PMB)? Ensure Pure SRB Cultures & Accurate MIC Research

- How is an autoclave utilized in antimicrobial experiments? Ensure Precise Nanoparticle Research Integrity