At its core, a vacuum furnace is used for high-temperature heat treatment processes where preventing chemical reactions with atmospheric gases is critical. Its primary applications include the brazing of complex assemblies, sintering of powdered metals, and the annealing or hardening of high-performance alloys. These processes are essential in industries like aerospace, medical device manufacturing, and high-end tool production.

A vacuum furnace is not just a hotter oven; it's a highly controlled environment. It is selected over other heat treatment methods when the absolute purity of the material and precise control over its final properties are more important than processing speed or initial equipment cost.

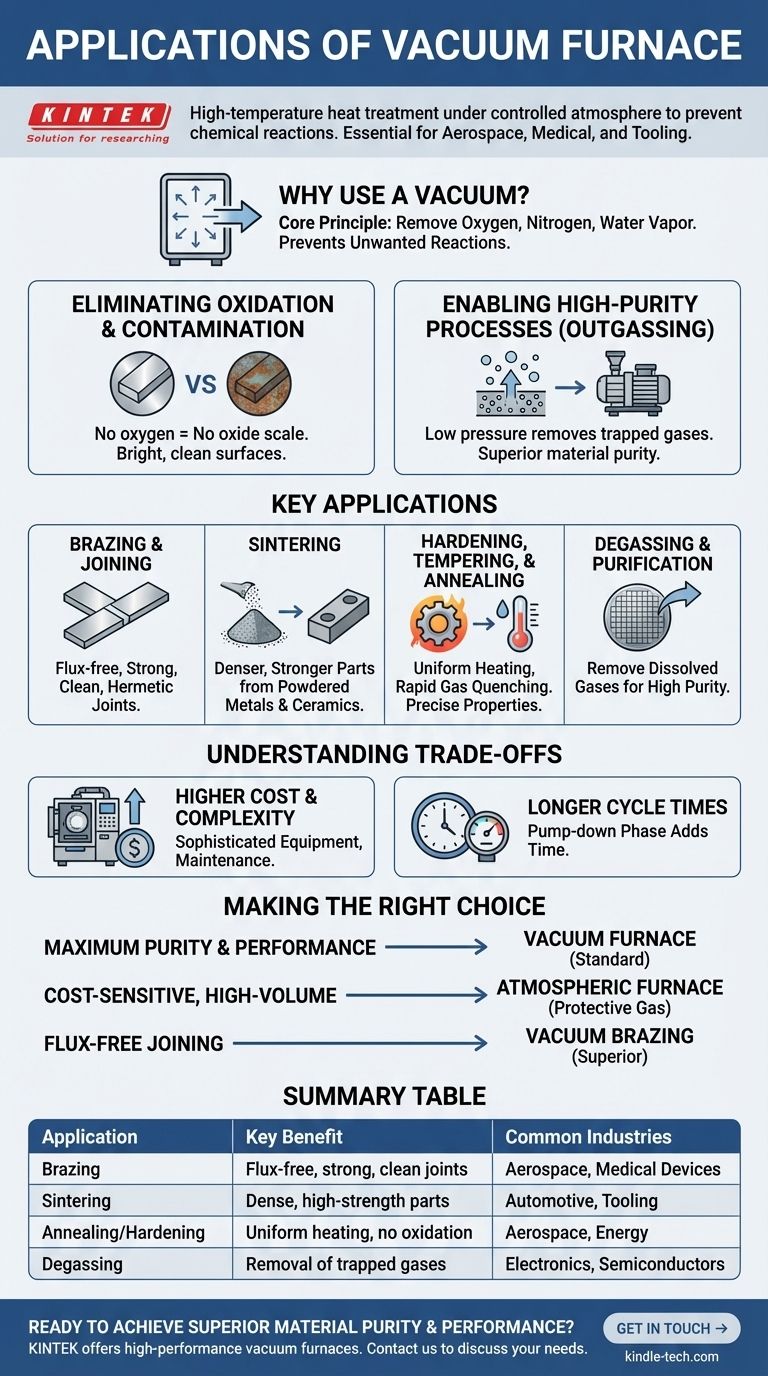

The Core Principle: Why Use a Vacuum?

The fundamental purpose of a vacuum furnace is to remove the atmosphere—primarily oxygen, nitrogen, and water vapor—from the heating chamber. This simple act of removing air unlocks several critical processing advantages by preventing unwanted chemical reactions at high temperatures.

Eliminating Oxidation and Contamination

When metals are heated, they readily react with oxygen in the air, forming a layer of oxide scale on the surface. This oxidation can ruin a part's surface finish, alter its dimensions, and create a weak point.

A vacuum environment effectively eliminates the oxygen, allowing materials to be heated to extreme temperatures while remaining bright, clean, and free from surface contamination.

Enabling High-Purity Processes

Beyond just preventing contamination, a vacuum can actively purify materials. The low-pressure environment encourages the release of trapped gases and other volatile impurities from within the material, a process known as outgassing.

These unwanted elements are then removed by the vacuum pumping system, resulting in a final product with higher purity and superior performance characteristics.

Key Applications Driven by Core Benefits

The controlled, clean environment of a vacuum furnace makes it the ideal choice for demanding applications where material integrity is non-negotiable.

Brazing and Joining

Brazing uses a filler metal to join two components. In a normal atmosphere, oxides on the component surfaces would prevent the filler metal from properly wetting and bonding, requiring aggressive chemical fluxes.

Vacuum brazing eliminates the need for flux, as the pristine, oxide-free surfaces allow the filler metal to flow freely and create an exceptionally strong, clean, and hermetic joint. This is critical for aerospace components and medical implants.

Sintering of Powdered Metals and Ceramics

Sintering is the process of fusing fine particles together using heat, just below their melting point. It's used to create solid components from powdered metals or ceramics.

Using a vacuum prevents trapped gases between the particles and ensures no impurities are introduced during heating. This results in a denser, stronger final part, essential for making cutting tools, automotive components, and porous filters.

Hardening, Tempering, and Annealing

These processes alter the microstructure of a metal to achieve desired mechanical properties like hardness, toughness, or ductility. A vacuum furnace provides two key advantages.

First, it offers exceptional temperature uniformity, ensuring the entire part is heated evenly. Second, the ability to perform rapid gas quenching (backfilling the chamber with an inert gas like argon or nitrogen) allows for precise, repeatable cooling rates without the risk of oxidation or surface decarburization.

Degassing and Purification

Some applications, particularly in electronics and scientific research, require materials that are almost completely free of dissolved gases.

Heating a material under a deep vacuum is the most effective way to pull these trapped gases out. This is essential for components used in other vacuum systems, like particle accelerators or semiconductor manufacturing equipment, where any outgassing could ruin the process.

Understanding the Trade-offs

While powerful, vacuum furnaces are not the universal solution for all heat treatment. Their benefits come with specific costs and limitations.

Higher Initial Cost and Complexity

Vacuum furnaces are sophisticated machines involving vacuum pumps, complex control systems, and specialized chamber designs. This makes them significantly more expensive to purchase and maintain than standard atmospheric furnaces.

Longer Cycle Times

Achieving a high vacuum is not instantaneous. The "pump-down" phase, where air is evacuated from the chamber before heating can begin, adds time to the overall process cycle. For high-volume production of simple parts, this can be a significant bottleneck.

Material Limitations

Not all materials are suitable for vacuum processing. Elements with a high vapor pressure, such as zinc, magnesium, cadmium, or lead, can turn into a gas (vaporize) under a combination of high heat and low pressure. This can damage the part and severely contaminate the furnace interior.

Making the Right Choice for Your Goal

The decision to use a vacuum furnace hinges on a clear understanding of your project's technical requirements and economic constraints.

- If your primary focus is maximum purity and performance: For mission-critical applications in aerospace, medical, or defense where failure is not an option, the clean, controlled environment of a vacuum furnace is the standard.

- If your primary focus is cost-sensitive, high-volume production: An atmospheric furnace using a protective gas (like nitrogen or argon) may be a more economical choice if minor surface oxidation or contamination is acceptable.

- If your primary focus is joining complex assemblies without flux: Vacuum brazing is the superior method for creating strong, clean, and void-free joints in intricate components.

Ultimately, choosing a vacuum furnace is a strategic decision to prioritize perfect metallurgical control over all other factors.

Summary Table:

| Application | Key Benefit | Common Industries |

|---|---|---|

| Brazing | Flux-free, strong, clean joints | Aerospace, Medical Devices |

| Sintering | Dense, high-strength parts from powder | Automotive, Tooling |

| Annealing/Hardening | Uniform heating, no oxidation | Aerospace, Energy |

| Degassing | Removal of trapped gases for high purity | Electronics, Semiconductors |

Ready to achieve superior material purity and performance in your lab?

At KINTEK, we specialize in high-performance vacuum furnaces designed for the most demanding applications in aerospace, medical device manufacturing, and advanced materials research. Our equipment ensures precise temperature control, contamination-free processing, and reliable results for brazing, sintering, annealing, and more.

Contact us today to discuss how a KINTEK vacuum furnace can enhance your laboratory's capabilities and deliver the quality your projects demand.

Get in touch with our experts →

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What is the primary function of a high-performance vacuum furnace? Master Precision Heat Treatment for Tool Steels

- What is the function of high vacuum furnaces for Inconel 718? Achieve Peak Superalloy Strength via Micro-Engineering

- What is a pyrolysis process? Transform Waste into Energy and Valuable Materials

- What machine is used for brazing? Choose the Right Heating Method for Your Application

- How does a vacuum drying oven contribute to the preparation of LNMO battery electrodes? Achieve Optimal Stability

- How does a sintering machine work? A Guide to Powder Metallurgy & Ceramic Fabrication

- Why is a high-vacuum environment necessary for sintering aluminum composites? Achieve Superior Bonding & Density

- Is brazing done in a vacuum furnace? Achieve Superior Joint Strength and Purity