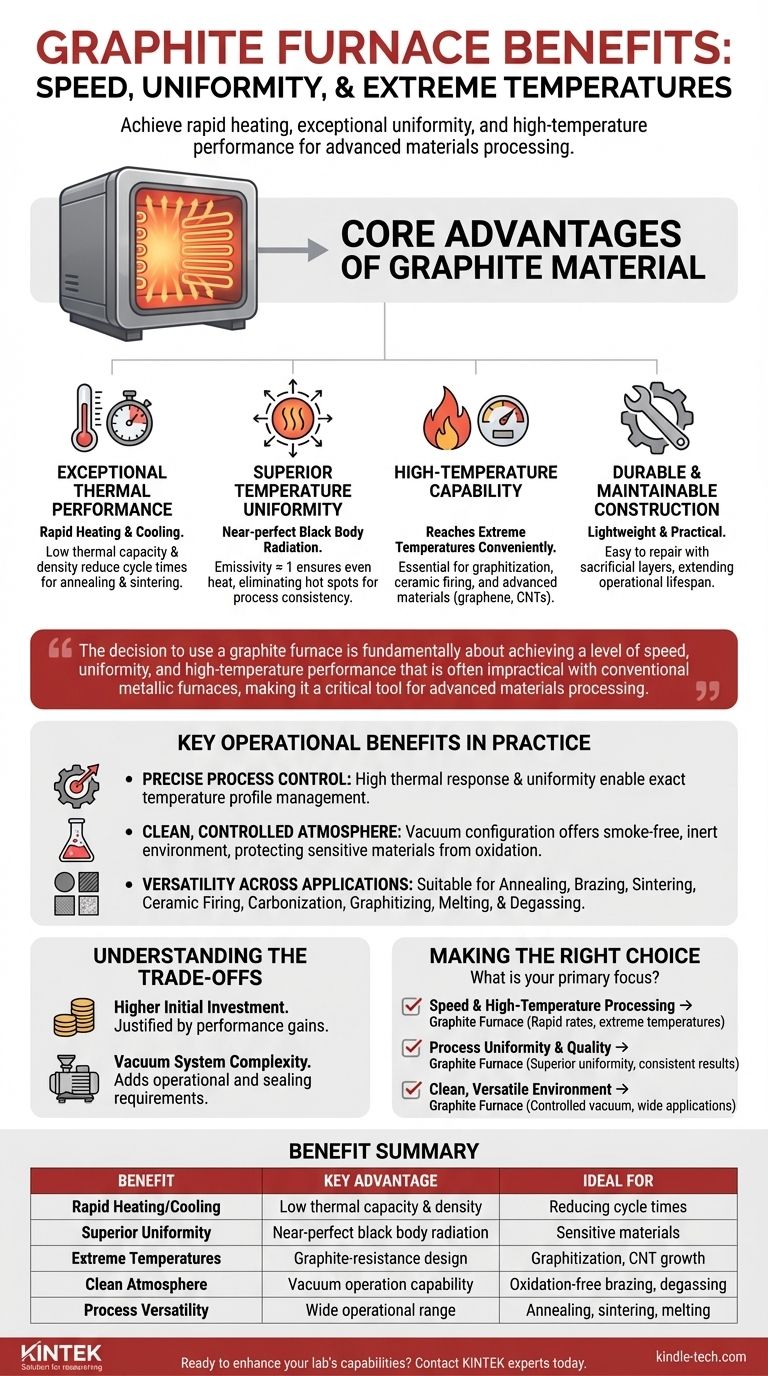

The primary benefits of a graphite furnace stem from the material's unique thermal properties, which allow for rapid heating, exceptional temperature uniformity, and the ability to reach extreme temperatures. Graphite's low density and low thermal capacity mean it heats and cools quickly, while its ability to create near-perfect black body conditions ensures heat is radiated evenly throughout the chamber.

The decision to use a graphite furnace is fundamentally about achieving a level of speed, uniformity, and high-temperature performance that is often impractical with conventional metallic furnaces, making it a critical tool for advanced materials processing.

The Core Advantages of Graphite as a Furnace Material

Graphite isn't just a convenient material; its intrinsic properties directly translate into superior performance for demanding thermal applications.

Exceptional Thermal Performance

Graphite has a very low thermal capacity and modest density.

This combination allows the furnace to heat up and cool down with remarkable speed, significantly reducing cycle times for processes like annealing or sintering.

Superior Temperature Uniformity

Graphite exhibits an emissivity of nearly 1, creating ideal black body radiation conditions inside the heating chamber.

This means heat is radiated incredibly evenly, eliminating hot spots and ensuring every part of the workload receives the same thermal energy, which is critical for process consistency.

High-Temperature Capability

Graphite furnaces, particularly graphite-resistance vacuum models, can reach higher temperatures more conveniently than many alternatives.

This makes them essential for high-temperature processes like graphitization, ceramic firing, and the growth of advanced materials like graphene or carbon nanotubes.

Durable and Maintainable Construction

Despite its high performance, graphite furnace chambers are also practical.

They are lightweight compared to metallic hot zones and are often designed to be easily repaired. Sacrificial layers can also be used to protect the core components and extend the furnace's operational lifespan.

Key Operational Benefits in Practice

These material advantages create tangible benefits in a laboratory or production environment.

Precise Process Control

The combination of rapid thermal response and high uniformity gives operators a very high degree of temperature controllability.

This precision is vital for complex processes where specific temperature profiles must be followed exactly.

Clean, Controlled Atmosphere

When used in a vacuum configuration, a graphite furnace provides a smoke-free, inert atmosphere.

This protects sensitive materials from oxidation and contamination, a requirement for applications like brazing and degassing.

Versatility Across Applications

The capabilities of graphite furnaces make them suitable for an exceptionally wide range of thermal processes.

Common applications include annealing, brazing, sintering, ceramic firing, carbonization, graphitizing, melting, and degassing of various materials.

Understanding the Trade-offs

While powerful, graphite furnaces come with specific considerations that must be weighed.

Higher Initial Investment

Graphite-resistance vacuum furnaces typically have a higher initial cost compared to simpler, lower-temperature furnace designs.

The investment is justified by the performance gains, but it is a key factor in initial planning.

Vacuum System Complexity

To achieve the cleanest atmosphere and highest temperatures, a vacuum system is often required.

This adds operational complexity, including the need to produce a vacuum and manage large, vacuum-tight seals during loading and unloading.

Making the Right Choice for Your Application

Selecting a furnace depends entirely on your process requirements and primary goals.

- If your primary focus is speed and high-temperature processing: A graphite furnace is an outstanding choice due to its rapid heating rates and ability to efficiently reach extreme temperatures.

- If your primary focus is process uniformity and quality: The superior temperature uniformity from graphite's black body conditions is essential for sensitive materials that demand consistent results.

- If your primary focus is a clean, versatile environment: The ability to operate in a controlled vacuum makes a graphite furnace ideal for a wide range of applications, from brazing metals to developing advanced carbon materials.

Ultimately, understanding these core benefits allows you to leverage the unique capabilities of graphite to master your most demanding thermal processes.

Summary Table:

| Benefit | Key Advantage | Ideal For |

|---|---|---|

| Rapid Heating/Cooling | Low thermal capacity & density | Reducing cycle times (e.g., annealing, sintering) |

| Superior Uniformity | Near-perfect black body radiation | Consistent results for sensitive materials |

| Extreme Temperatures | Graphite-resistance design | Graphitization, ceramic firing, CNT growth |

| Clean Atmosphere | Vacuum operation capability | Oxidation-free brazing, degassing |

| Process Versatility | Wide operational range | Annealing, sintering, melting, carbonization |

Master your most demanding thermal processes with a graphite furnace from KINTEK.

Our graphite furnaces are engineered to deliver the rapid heating, exceptional temperature uniformity, and high-temperature performance your advanced materials research or production requires. Whether your application involves sintering, brazing, graphitization, or ceramic firing, KINTEK's expertise in lab equipment ensures you get a reliable solution tailored to your needs.

Ready to enhance your lab's capabilities? Contact our experts today to discuss how a graphite furnace can solve your specific high-temperature challenges.

Visual Guide

Related Products

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- Why is graphite used in furnaces? For Extreme Heat, Purity, and Efficiency

- What is the purpose of a graphite furnace? Achieve Extreme Temperatures for Advanced Materials

- What are the advantages of graphite furnace? Achieve High-Temperature Precision and Purity

- Does graphite have a melting point? Unlocking the Extreme Heat Resistance of Graphite

- What is the temperature range of a graphite furnace? Unlock up to 3000°C for advanced materials processing.