The core benefits of microwave plasma processing are its exceptional speed, energy efficiency, and unique volumetric heating mechanism. Unlike conventional ovens that heat from the outside-in, microwaves energize the material internally, leading to a faster, cleaner, and more uniform process for applications like ceramic sintering and material synthesis.

Microwave processing fundamentally changes how materials are heated. By directly energizing a material's internal structure, it bypasses the slow, inefficient transfer of heat from an external source, leading to faster results, superior uniformity, and significant energy savings.

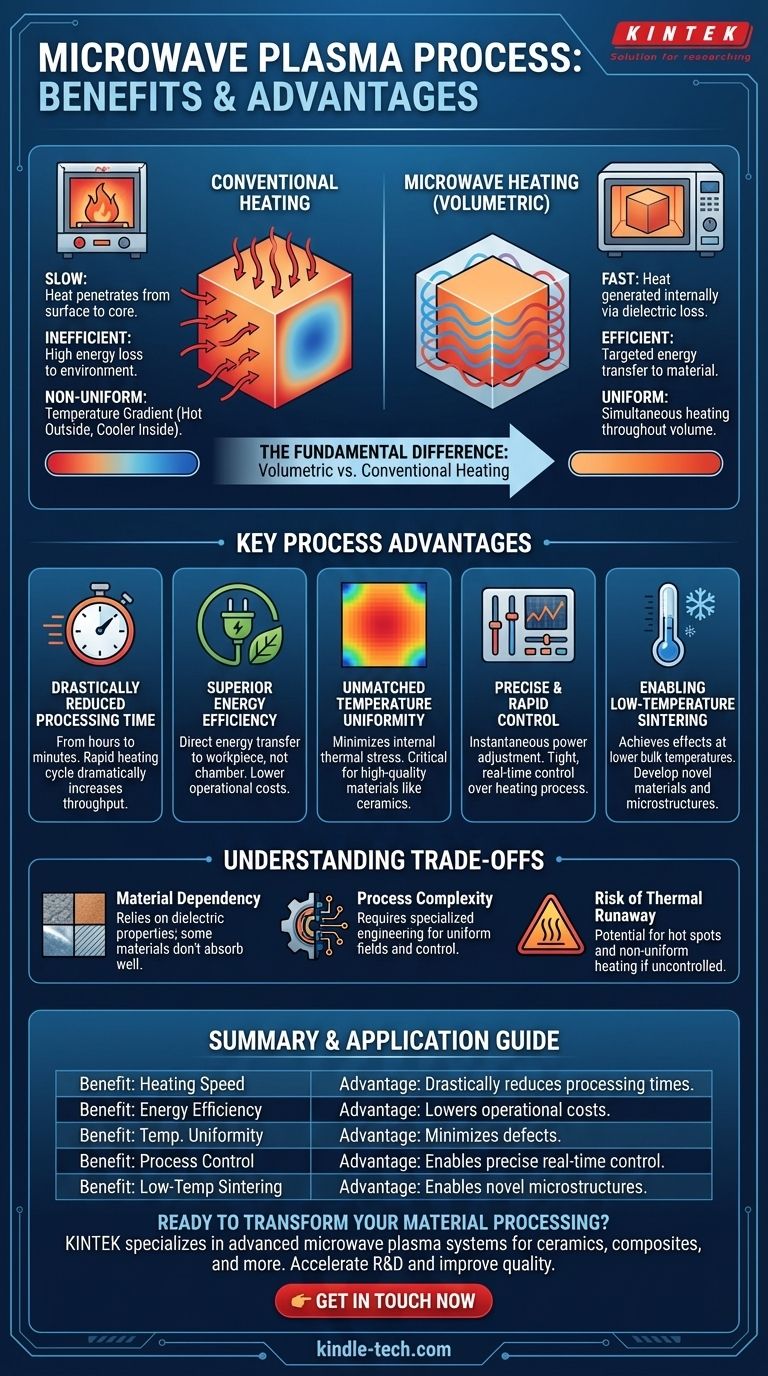

The Fundamental Difference: Volumetric vs. Conventional Heating

To understand the benefits of microwave plasma, you must first understand how it differs from traditional heating methods. The distinction lies in how energy is delivered to the material.

How Conventional Heating Works

Traditional furnaces operate via external heat sources. Energy is transferred to the material's surface through conduction, convection, and radiation.

This process is inherently slow, as the heat must gradually penetrate from the surface to the core. It also creates a temperature gradient, where the outside of the material is significantly hotter than the inside.

How Microwave Heating Works

Microwave processing uses an electromagnetic field to deliver energy. The microwaves penetrate the material and interact directly with its molecules.

This interaction causes the molecules to oscillate rapidly, generating heat through a principle known as dielectric loss. In essence, the material heats itself from the inside out, a process called volumetric heating.

The Result: Uniformity and Speed

Because heat is generated throughout the entire volume of the material simultaneously, the process is incredibly fast. It also results in a much more uniform temperature profile, minimizing the internal thermal stress that can compromise material quality.

Key Process Advantages Explained

This unique heating mechanism translates into several distinct operational advantages over conventional methods.

Drastically Reduced Processing Time

By heating the material directly and volumetrically, microwave plasma systems can reduce processing times from many hours to mere minutes. This rapid heating cycle dramatically increases throughput.

Superior Energy Efficiency

Energy is delivered directly to the workpiece, not wasted on heating the furnace chamber walls and insulation. This targeted approach results in significantly higher energy efficiency and lower operational costs.

Unmatched Temperature Uniformity

Generating heat from within the material nearly eliminates the temperature gradients common in conventional heating. This uniformity is critical for producing high-quality, defect-free advanced materials like ceramics.

Precise and Rapid Control

Microwave power can be turned on, off, or adjusted instantaneously. This gives operators tight, real-time control over the heating process, unlike thermal furnaces which have significant lag time due to thermal inertia.

Enabling Low-Temperature Processing

The efficiency of microwave energy can achieve effects like sintering at a lower overall bulk temperature compared to conventional methods. This ability for low-temperature, rapid sintering is crucial for developing novel materials and microstructures.

Understanding the Trade-offs

While powerful, microwave processing is not a universal solution. Understanding its limitations is key to successful implementation.

Material Dependency

The process relies on the material's ability to absorb microwave energy (its dielectric properties). Materials with very low dielectric loss, such as certain pure polymers or metals in bulk form, do not heat effectively on their own.

Process Complexity

Microwave plasma systems are more technically complex than a simple resistance furnace. Designing a uniform electromagnetic field and preventing thermal runaway requires specialized engineering and operational knowledge.

Risk of Thermal Runaway

In materials where microwave absorption increases with temperature, a positive feedback loop can occur. If not properly controlled, this can lead to "hot spots" and non-uniform heating, potentially damaging the material.

Making the Right Choice for Your Application

Selecting the right heating technology depends entirely on your project's specific goals and materials.

- If your primary focus is rapid production and high throughput: Microwave processing is an excellent choice due to its significantly shorter cycle times.

- If your primary focus is processing advanced ceramics or composites: The uniform, controlled heating offers superior quality and can create microstructures not achievable with conventional methods.

- If your primary focus is energy savings and process sustainability: The high efficiency of direct energy transfer makes it a greener and more cost-effective choice for long-term production.

Ultimately, microwave plasma processing offers a level of speed, control, and efficiency that can unlock new possibilities in material science and advanced manufacturing.

Summary Table:

| Benefit | Key Advantage |

|---|---|

| Heating Speed | Drastically reduces processing times from hours to minutes. |

| Energy Efficiency | Direct energy transfer to material lowers operational costs. |

| Temperature Uniformity | Volumetric heating minimizes internal thermal stress and defects. |

| Process Control | Instantaneous power adjustment enables real-time, precise control. |

| Low-Temperature Sintering | Enables novel material microstructures at lower bulk temperatures. |

Ready to transform your material processing with microwave plasma technology?

KINTEK specializes in advanced lab equipment, including microwave plasma systems designed for the precise needs of laboratories working with ceramics, composites, and advanced materials. Our solutions deliver the speed, uniformity, and energy efficiency detailed in this article, helping you accelerate R&D and improve product quality.

Contact our experts today to discuss how a microwave plasma system from KINTEK can benefit your specific application. We'll help you unlock new possibilities in material science and manufacturing.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Multi-zone Laboratory Tube Furnace

- Spark Plasma Sintering Furnace SPS Furnace

People Also Ask

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition

- What is the floating catalyst method? A Guide to High-Yield CNT Production

- What role does Chemical Vapor Deposition (CVD) equipment play in the preparation of C/C composites? Expert Analysis

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit