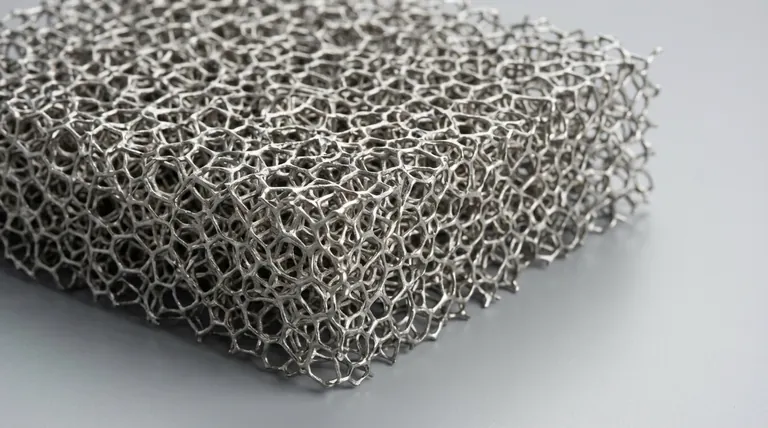

At its core, nickel foam is a highly porous metallic structure. It combines the inherent properties of nickel—such as conductivity and chemical stability—with a unique three-dimensional, sponge-like architecture. This results in a material with an exceptionally high surface area, excellent electrical conductivity, and significant empty volume, making it suitable for a wide range of advanced applications.

The true value of nickel foam lies not just in its metallic properties but in its structure. It functions as a high-surface-area, conductive scaffold, making it an ideal platform for applications that require maximum interaction between a solid material and a liquid or gas.

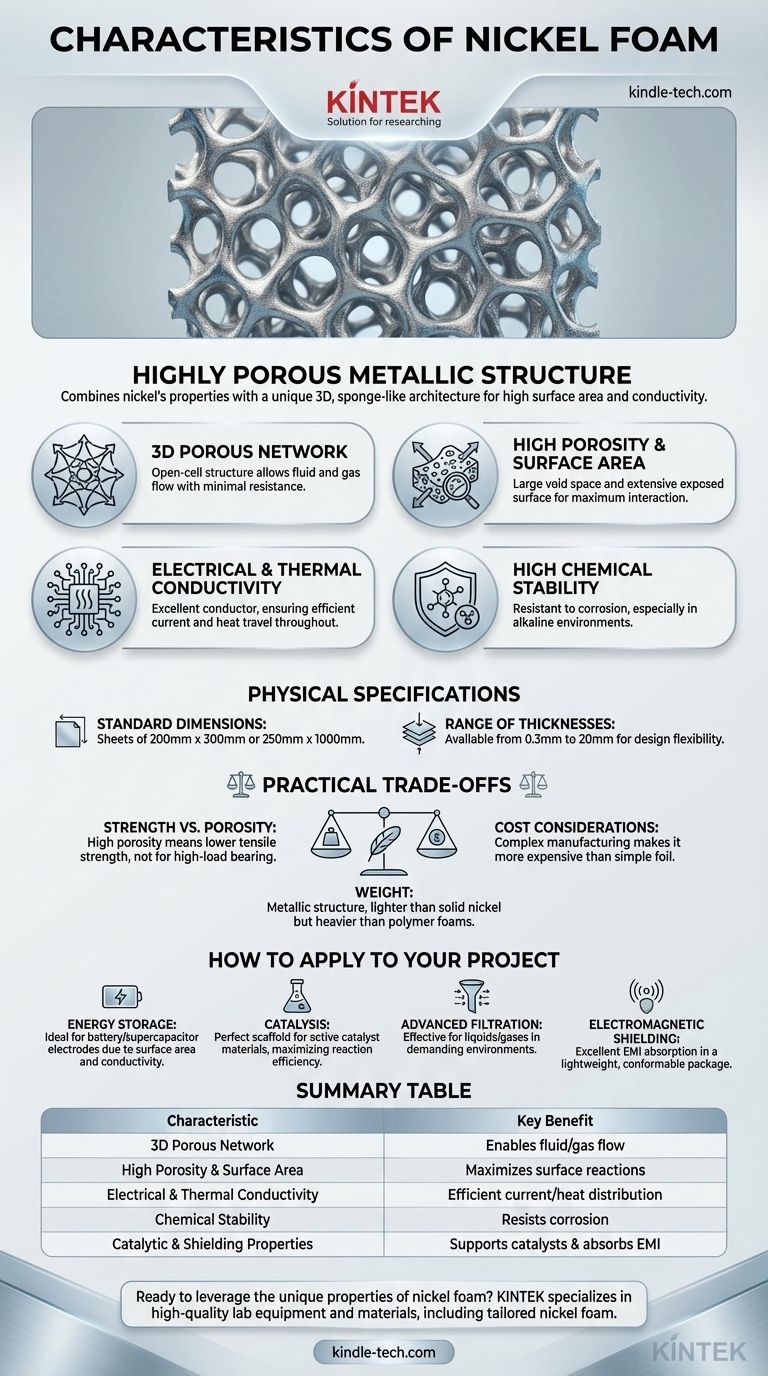

Deconstructing the Core Properties

To understand if nickel foam is the right choice for your project, it's essential to analyze its defining characteristics and what they enable.

The 3D Porous Network

This is the foundational characteristic. Unlike a perforated sheet, nickel foam is an open-cell structure, meaning its pores are interconnected in a web-like fashion. This allows fluids and gases to flow through it with minimal resistance.

High Porosity & Large Specific Surface Area

These two properties are intertwined. High porosity refers to the large percentage of void space within the material, while the large specific surface area is the total exposed surface of the nickel "skeleton" within that volume. This combination is critical for applications where surface reactions are key.

Electrical and Thermal Conductivity

As it is composed of nickel, the foam is an excellent conductor of both electricity and heat. The continuous metallic network ensures that current or heat can travel efficiently throughout the entire structure, which is vital for use in electrodes or heat exchangers.

High Chemical Stability

Nickel is inherently resistant to corrosion, especially in alkaline environments. This stability allows the foam to be used as a current collector in batteries or as a filter in chemically demanding situations without significant degradation.

Catalytic and Shielding Properties

The material serves as an excellent support for catalysts, where its vast surface area can be coated with active materials to accelerate chemical reactions. Furthermore, its conductive network is highly effective at absorbing and dissipating electromagnetic interference (EMI), making it a valuable shielding material.

Understanding the Physical Specifications

Beyond its chemical and structural properties, the physical form of nickel foam is a key practical consideration.

Standard Dimensions

Nickel foam is typically manufactured in sheets of standard sizes, such as 200mm x 300mm or 250mm x 1000mm. This allows for easier integration into manufacturing processes.

Range of Thicknesses

The availability of various thicknesses, from a very thin 0.3mm up to a robust 20mm, provides significant design flexibility. Thinner foams are ideal for compact applications like battery electrodes, while thicker versions can be used for more substantial filters or structural supports.

The Practical Trade-offs

No material is perfect for every use case. Understanding the inherent limitations of nickel foam is crucial for making an informed decision.

Strength vs. Porosity

The high porosity that makes nickel foam so useful also means it has lower tensile and shear strength compared to a solid nickel sheet of the same dimensions. It is a structural material, but not intended for high-load-bearing applications.

Cost Considerations

The complex manufacturing process required to create a metallic foam makes it more expensive than simple nickel foil or mesh. This cost must be weighed against the performance benefits it provides for a specific application.

Weight

While the foam structure reduces its density compared to solid nickel, it is still a metallic material. For applications where weight is the absolute top priority, other materials like carbon or polymer foams might be more suitable alternatives.

How to Apply This to Your Project

Your choice to use nickel foam should be directly tied to the primary goal you need to achieve.

- If your primary focus is energy storage (batteries, supercapacitors): The combination of high surface area, conductivity, and chemical stability makes it an elite choice for electrode current collectors.

- If your primary focus is catalysis: Its porous structure is a perfect scaffold for supporting active catalyst materials, maximizing reaction efficiency.

- If your primary focus is advanced filtration: The interconnected pores and chemical resistance allow for the effective filtration of liquids or gases in demanding environments.

- If your primary focus is electromagnetic shielding: The conductive 3D network provides excellent EMI absorption in a lightweight and conformable package.

Ultimately, nickel foam's unique blend of structural and chemical properties makes it a versatile and high-performance material for specialized engineering challenges.

Summary Table:

| Characteristic | Key Benefit |

|---|---|

| 3D Porous Network | Enables fluid/gas flow with minimal resistance |

| High Porosity & Surface Area | Maximizes surface reactions for efficiency |

| Electrical & Thermal Conductivity | Ensures efficient current/heat distribution |

| Chemical Stability | Resists corrosion, ideal for harsh environments |

| Catalytic & Shielding Properties | Supports catalysts and absorbs EMI effectively |

Ready to leverage the unique properties of nickel foam in your project? KINTEK specializes in high-quality lab equipment and consumables, including materials like nickel foam tailored for advanced applications in energy storage, catalysis, and filtration. Our expertise ensures you get the right materials to enhance your lab's performance and innovation. Contact us today to discuss your specific needs and discover how we can support your success!

Visual Guide

Related Products

- Copper Nickel Foam Metal Sheet

- Copper Foam

- High Purity Zinc Foil for Battery Lab Applications

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- Aluminum Foil Current Collector for Lithium Battery

People Also Ask

- Why is vacuum drying equipment used for composite sulfur cathodes? Protect Active Materials & Boost Battery Performance

- What are the advantages of a customized battery test mold with a force sensor? Master Pressure-Impedance Correlation.

- What role does the grinding process play in LAGP-IL hybrid pastes? Optimize Your Battery Intermediate Layers

- How should carbon cloth and carbon paper be cleaned after use? Preserve Material Integrity with Proper Care

- What are the critical operational considerations for mixing and grinding cathode powders in solid-state batteries?

- Why is a customized pressure device used for solid-state batteries? Master Stack Pressure for Stable Battery Cycling

- How is a high-precision electrochemical workstation utilized in cathode preparation? Precision Catalyst Deposition

- What role does a high-temperature annealing furnace play in the crystallization process of Li-argyrodite? Find out here