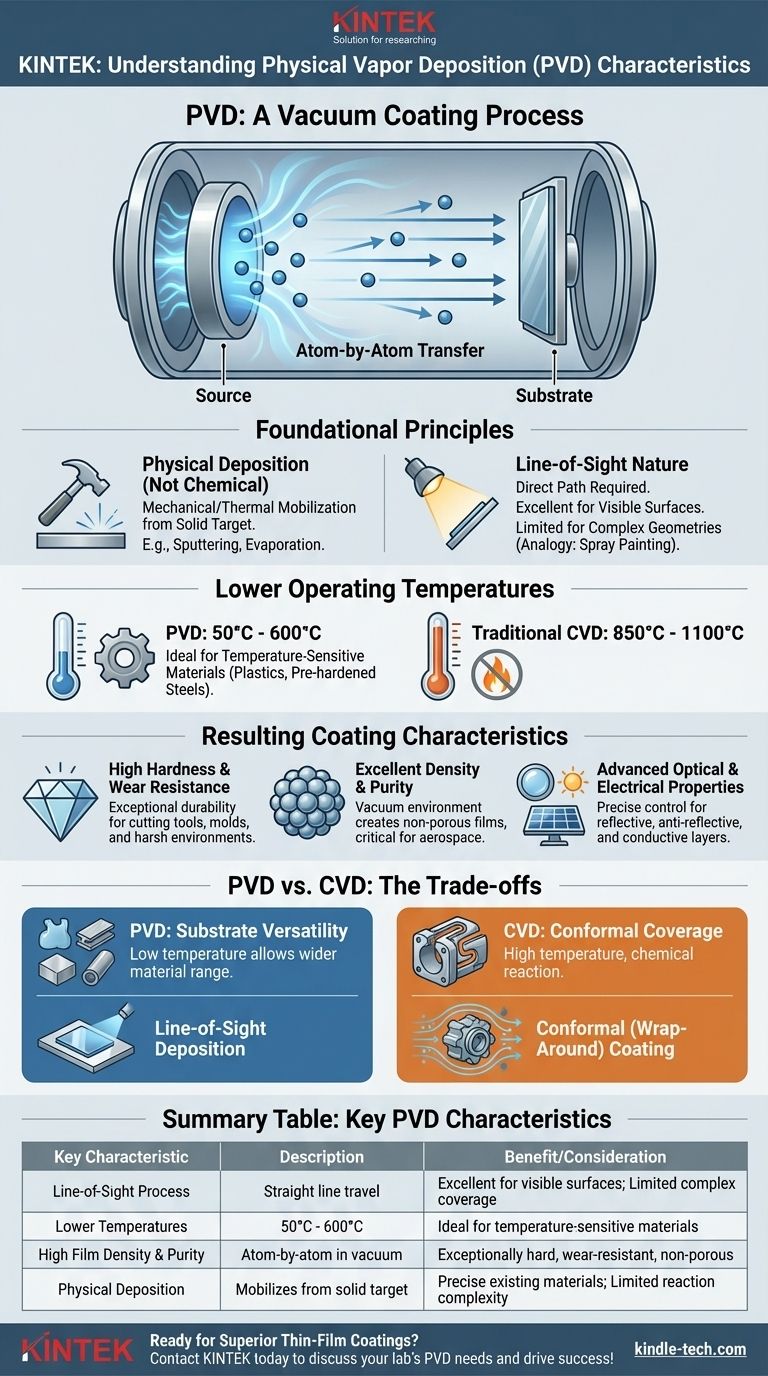

At its core, Physical Vapor Deposition (PVD) is a vacuum coating process that transfers material from a solid source, atom by atom, onto a substrate. Key characteristics include its "line-of-sight" application, its ability to operate at lower temperatures than conventional Chemical Vapor Deposition (CVD), and its capacity to produce exceptionally dense, hard, and pure thin films. This makes it ideal for applying wear-resistant or optical coatings to surfaces that directly face the deposition source.

The defining characteristic of PVD is its physical, line-of-sight nature. Unlike chemical processes that can "wrap around" an object, PVD excels at depositing high-performance coatings onto visible surfaces with precision, making the choice between PVD and other methods a question of geometry and temperature sensitivity.

The Foundational Principles of PVD

To understand PVD's characteristics, you must first grasp its fundamental mechanism. It is a physical process, not a chemical one, which dictates its primary advantages and limitations.

What "Physical" Deposition Means

PVD involves mechanically or thermally mobilizing atoms from a solid "target" material inside a vacuum chamber. Methods like sputtering (using ion bombardment) or evaporation (using heat or an electron beam) physically knock loose or boil off atoms from the source. These atoms then travel through the vacuum and condense onto the substrate, forming a thin film.

The "Line-of-Sight" Nature

Because the coating material travels in a straight line from the source to the substrate, PVD is considered a line-of-sight process. Any surface that is not in the direct path of the material vapor will not be coated effectively. This is analogous to spray painting; you cannot paint the back of an object without rotating it to face the nozzle.

Lower Operating Temperatures

PVD processes typically operate at significantly lower temperatures (often between 50°C and 600°C) than traditional Chemical Vapor Deposition (CVD), which can require temperatures of 850°C to 1100°C. This makes PVD suitable for coating materials that cannot withstand high heat, such as certain plastics, alloys, or pre-hardened steels.

Resulting Coating Characteristics

The physical, line-of-sight nature of the PVD process directly results in films with distinct and valuable properties.

High Hardness and Wear Resistance

PVD coatings are known for their exceptional hardness and resistance to wear and corrosion. This is why the technique is widely used for coating cutting tools, molds, and other components used in harsh industrial environments.

Excellent Density and Purity

The vacuum environment ensures very few impurities are incorporated into the film. The atom-by-atom deposition process results in a coating that is extremely dense and non-porous. This density is critical for applications like aerospace components, where it contributes to temperature resistance and durability.

Advanced Optical and Electrical Properties

PVD allows for precise control over film thickness and composition. This makes it a go-to method for creating optical films with specific reflective or anti-reflective properties for solar panels, glass, and semiconductors, as well as conductive layers for electronics.

Understanding the Trade-offs: PVD vs. CVD

No single technology is universally superior. The true value of PVD becomes clear when contrasted with its primary alternative, Chemical Vapor Deposition (CVD).

Advantage: Substrate Versatility

PVD's lower operating temperature is a significant advantage. It allows for the coating of a much wider range of substrate materials without risk of damage, deformation, or metallurgical changes that can be induced by the high heat of traditional CVD.

Limitation: Conformal Coverage

This is the most critical trade-off. Because PVD is line-of-sight, it struggles to provide a uniform coating on parts with complex geometries, such as internal channels, undercuts, or threaded holes. In contrast, CVD is a non-line-of-sight process where precursor gases can flow around an object, resulting in a highly uniform, or conformal, coating on all surfaces.

Material Deposition vs. Creation

PVD physically transfers a source material onto a substrate. While reactive gases can be introduced to form some compounds, it is fundamentally a process of moving an existing material. CVD relies on chemical reactions at the substrate surface to create an entirely new material, offering a different and often wider range of deposit possibilities, including multi-component alloys and complex ceramic layers.

Making the Right Choice for Your Application

Your final decision must be driven by the specific requirements of your component and its end-use environment.

- If your primary focus is coating a complex part with internal surfaces: Choose CVD for its superior "wrap-around" capability and uniform coverage.

- If your primary focus is applying a hard, durable coating to a visible surface: Choose PVD for its line-of-sight precision and excellent film density and hardness.

- If your primary focus is coating a temperature-sensitive material: PVD is the clear choice due to its significantly lower process temperatures.

Ultimately, understanding the fundamental distinction between PVD's physical transfer and CVD's chemical reaction is the key to selecting the ideal technology for your goal.

Summary Table:

| Key Characteristic | Description | Benefit/Consideration |

|---|---|---|

| Line-of-Sight Process | Coating material travels in a straight line from source to substrate. | Excellent for visible surfaces; limited coverage on complex geometries. |

| Lower Operating Temperatures | Typically operates between 50°C and 600°C. | Ideal for temperature-sensitive materials like plastics and pre-hardened steels. |

| High Film Density & Purity | Atom-by-atom deposition in a vacuum environment. | Creates exceptionally hard, wear-resistant, and non-porous coatings. |

| Physical Deposition | Mechanically or thermally mobilizes atoms from a solid target. | Deposits existing materials precisely; limited chemical reaction complexity. |

Ready to leverage PVD's precision for your lab's coating needs?

At KINTEK, we specialize in providing high-quality lab equipment and consumables, including advanced PVD systems. Our solutions are designed to help you achieve superior thin-film coatings with exceptional hardness, density, and purity—perfect for applications in tooling, optics, and electronics.

Let our experts help you select the right PVD technology to enhance your research and production. Contact KINTEK today to discuss your specific requirements and discover how our reliable lab equipment can drive your success!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is plasma CVD? Unlock Low-Temperature Thin Film Deposition for Sensitive Materials

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing

- What is the plasma CVD process? Achieve Low-Temperature Thin Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Coating Solution for Sensitive Materials

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition